Method for preparing small crystal grain molecular sieve

A technology of molecular sieves and small crystals, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of high production cost, difficult product separation, long production cycle, etc., and achieve the effect of strong activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

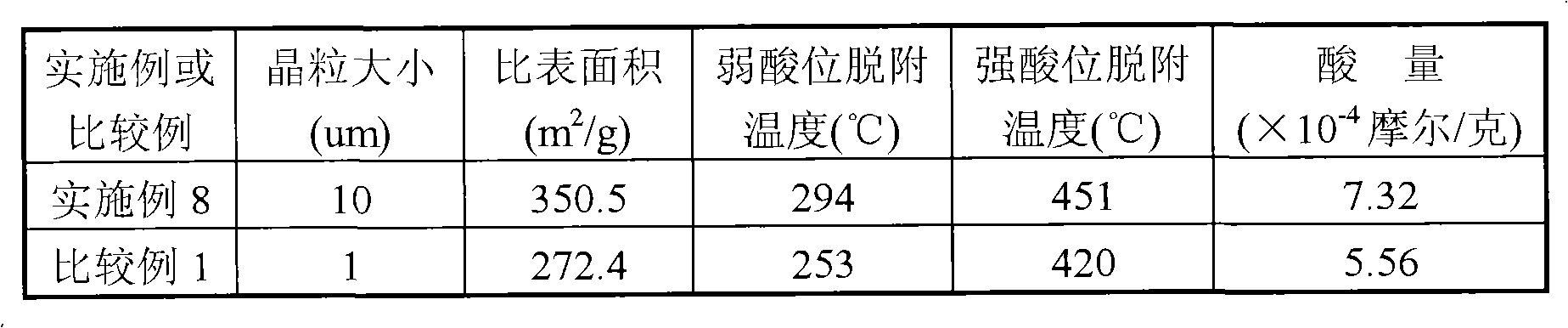

Embodiment 1

[0016] Take 500 grams of SiO with a grain size of 10um 2 / Al 2 O 3 ZSM-5 molecular sieve of 40 is placed in the feeder of the supersonic jet mill, the feed rate of the feeder is adjusted to 1 kg / h, and the air inlet air pressure of the jet mill is set to 2Mpa. After crushing, the cyclone separation is large. The granular crystals were newly put into the feeder for airflow crushing, and after repeated two times, a small crystal ZSM-5 molecular sieve with an average particle size of 1um was obtained.

Embodiment 2

[0018] Take 500 grams of mordenite with a grain size of 5um and put it into the feeder of the supersonic jet mill, adjust the feed rate of the feeder to 0.5 kg / h, and set the supersonic jet mill inlet air pressure to 3Mpa for crushing Afterwards, the large-particle crystals separated by the cyclone were newly put into the feeder for airflow crushing, and after repeated twice, small-crystal mordenite with an average particle size of 0.5um was obtained.

Embodiment 3

[0020] Take 200 grams of mordenite with a grain size of 5um and put it into the feeder of the supersonic jet mill. Adjust the feed rate of the feeder to 0.2 kg / h. Set the air inlet air pressure of the jet mill to 5Mpa. After crushing, The large-particle crystals separated by the cyclone are newly put into the feeder for airflow crushing. After repeating 3 times, all the obtained small-crystal molecular sieves are put into the feeder. After repeating the above process twice, the average particle size is 0.1um. Of small grains of mordenite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com