Fiber body strain gauge

A technology of body strain and strain gauge, applied in instruments, optical devices, measuring devices, etc., can solve problems such as electromagnetic interference, lightning protection, zero drift, etc., and achieve the effect of reducing zero drift problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

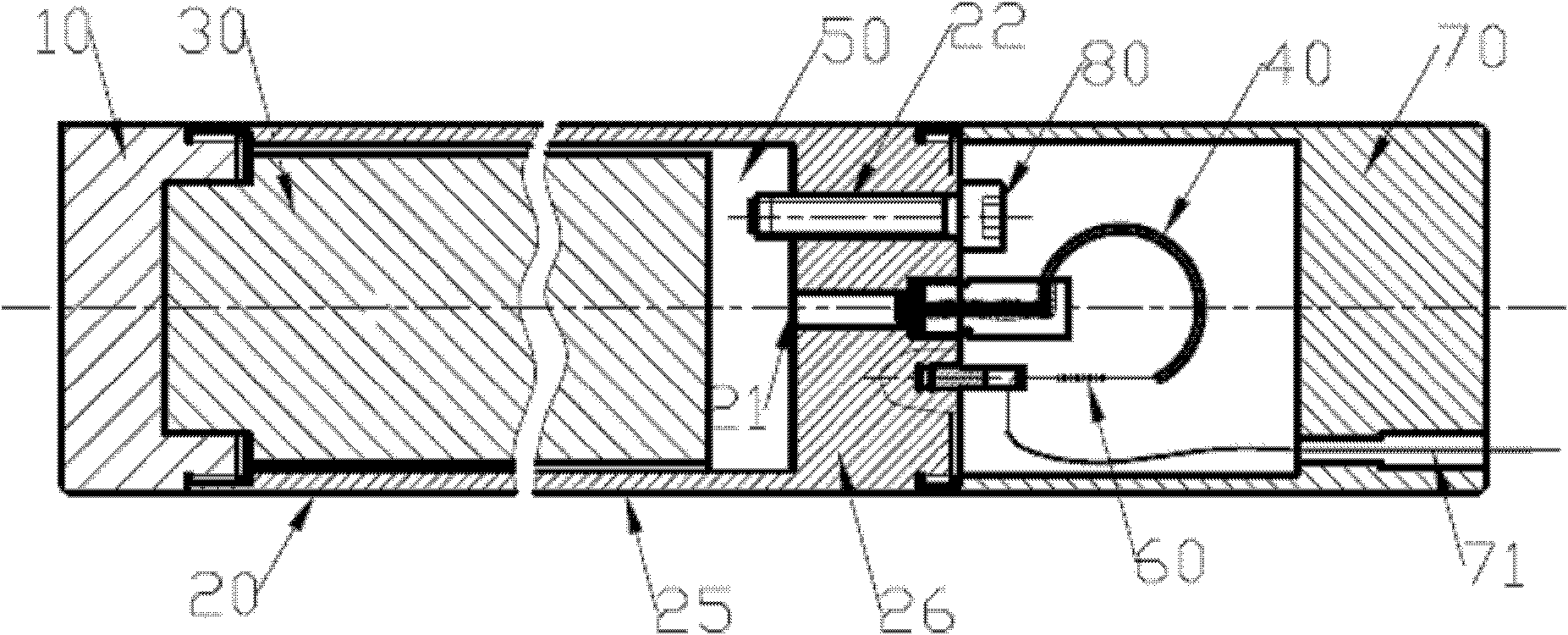

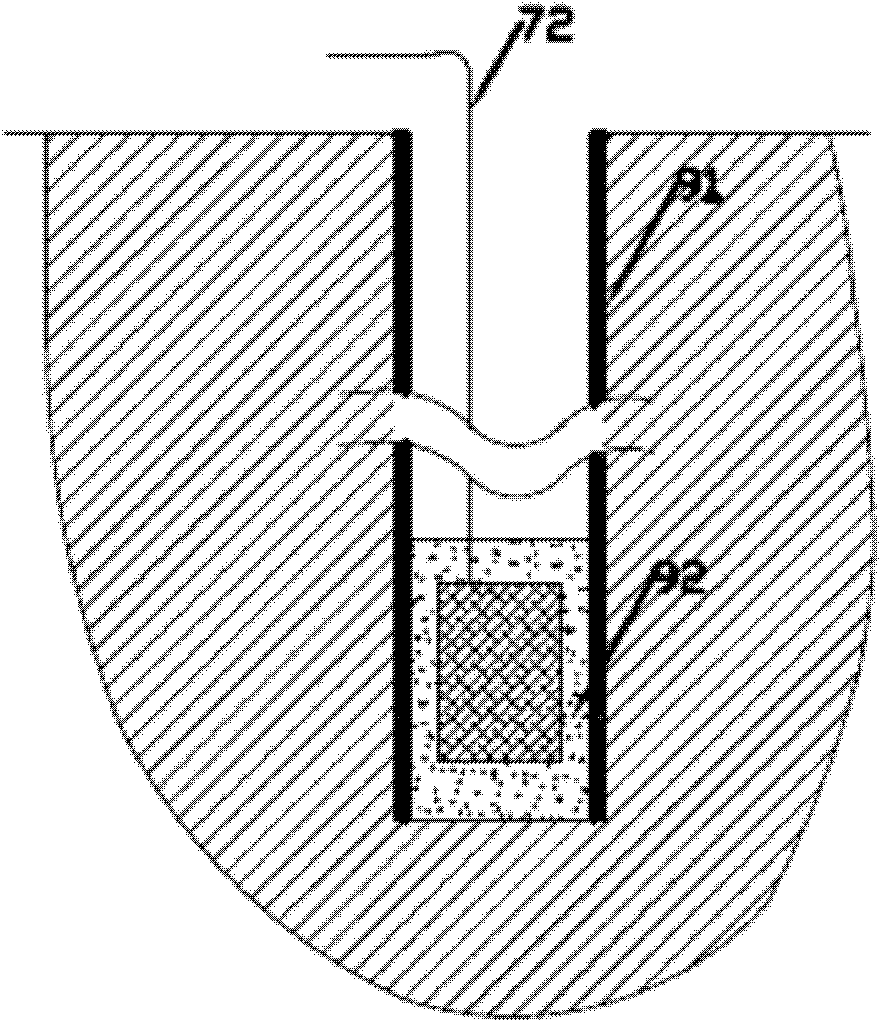

[0025] Please refer to Figure 1-Figure 2 , the optical fiber body strain gauge provided by the present invention includes: a strain cylinder 20 for sensing body strain; filling the liquid 50 in the strain cylinder 20 for transmitting the body strain felt by the strain cylinder 20; an end cap 10 for sealing; The spring tube 40 installed at the bottom of the strain tube 20 is used to sense the pressure change in the strain tube 20; the bolt 80 installed at the bottom of the strain tube 20 is used for filling the liquid 50 and sealing it; it is fixed at the bottom of the spring tube 40 and the strain tube 20 The fiber grating 60 at the end is used to measure the end displacement of the spring tube 40; the protective cover 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com