Injection mold screw thread core pulling mechanism

A core-pulling mechanism and injection mold technology, which is applied to threaded products, other household appliances, household appliances, etc., can solve the problems of large power and volume of servo motors, increase the volume occupied by molds, and difficulty in ensuring accuracy, and achieve push-out resistance Stable and uniform, easy to ensure manufacturing accuracy, and simplified mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

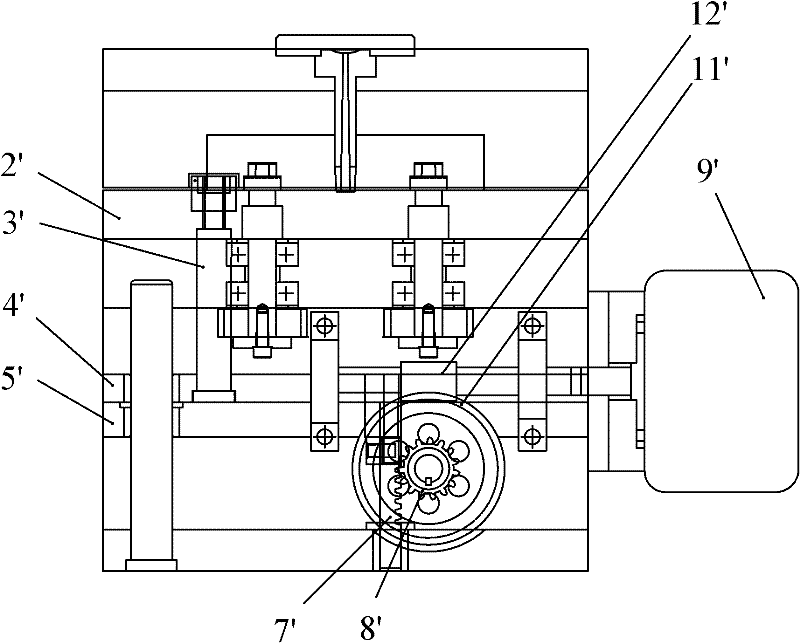

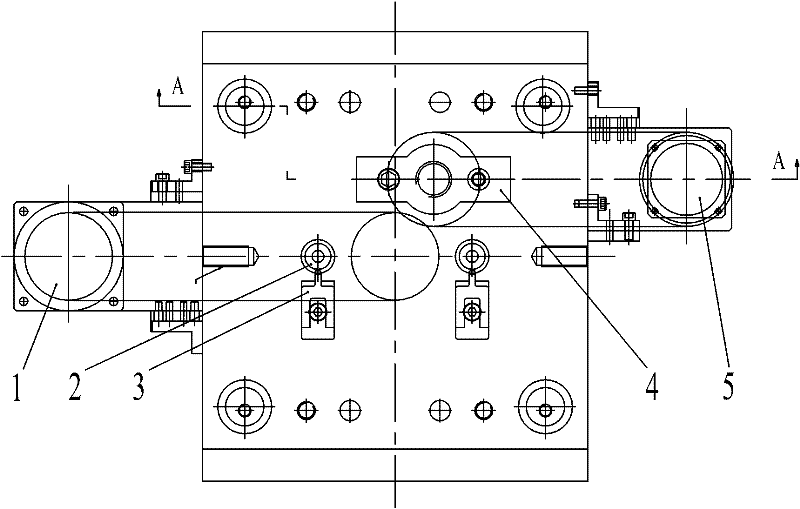

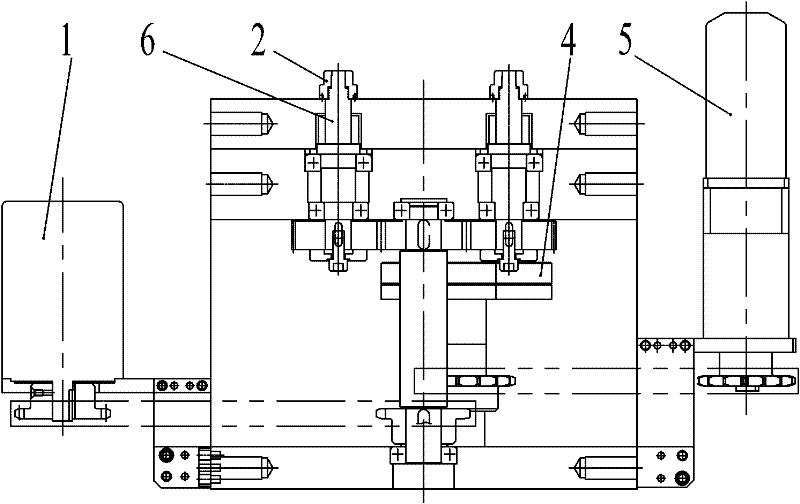

[0027] see figure 2 one Figure 4 , the threaded core-pulling mechanism of the injection mold includes a fixed template, a movable template, an injection molded part 2 and a threaded core 6 in the mold cavity, and a core-pulled mechanism for the threaded core 6, which is located at the bottom of the plastic injection molded part 2 and The push plate 11 and the push plate synchronous ejection mechanism for synchronous ejection during thread core pulling, the thread core 6 is connected with the core pulling mechanism, the push plate 11 is connected with the synchronous ejection mechanism, and the control system controls the motor speed of the two mechanisms so that the thread The stroke of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com