Curvature radius measuring method

A technology of curvature radius and measurement method, applied in the field of measurement, can solve the problems of not being able to find an autocollimation image, not suitable for the on-site working environment, and taking a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] specific implementation plan

[0020] The present invention will be described in detail below with reference to the drawings and embodiments.

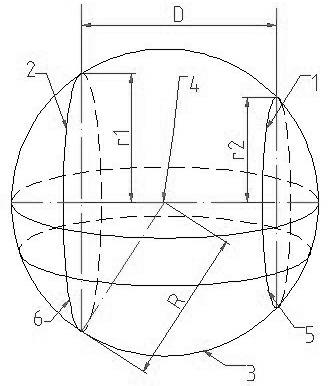

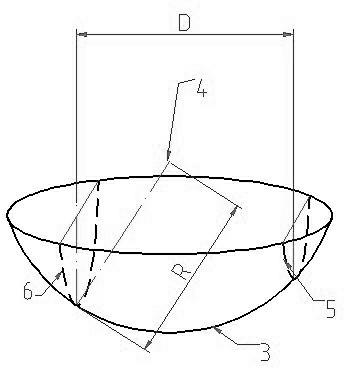

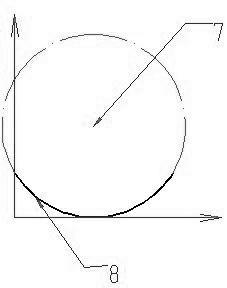

[0021] The design principle of the present invention is: the spherical surface to be measured of any optical spherical lens can be considered to be obtained by cutting from a complete spherical surface, so the measurement of the radius of curvature of the spherical surface can be attributed to measuring the spherical radius of the complete spherical surface. ( ) Two known parallel planes (the distance is less than the diameter of the ball) cut the ball, and the intersection line with the surface of the ball forms two circles, through non-contact measurement methods (such as triangulation, laser ranging, optical fiber Displacement sensing distance measurement method, super life distance measurement method, and distance measurement method based on the principle of capacitive transformation) to obtain the radius of the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com