Method for determining tempering temperature

A technology of tempering temperature and tempering hardness, applied in the field of computer-aided heat treatment process design, can solve the problems of poor consistency and standardization, complexity and low efficiency of tempering process, low efficiency of process selection, etc. Improve process design efficiency and select reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

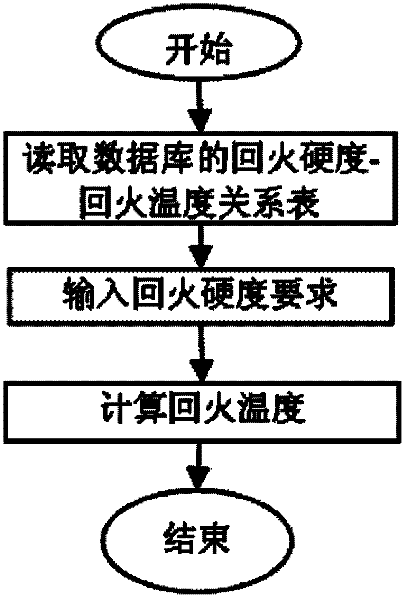

[0031] Such as figure 1 and figure 2 As shown, this embodiment includes the following steps:

[0032] (1) The parts material of the present embodiment is 40Cr, read the tempering hardness-tempering temperature relational table in the database, as shown in table 1, the tempering hardness-tempering temperature relational table in the database is selected from Wang Xiankui, "Material and Its Heat Treatment", Machining Handbook (Single Book) ISBN 978-7-111-24249-9: Page 265, 2008.6.1.

[0033] (2) Determine the tempering temperature according to the tempering hardness requirement input by the user as HRC42-52, including:

[0034] 1) Standardized tempering hardness requirements: the tempering hardness input by the user is required to span 3 intervals or more intervals;

[0035] Take the original tempering hardness range, that is, the intermediate value HRC47 of the tempering hardness requirement input by the user, as the normalized tempering hardness;

[0036] 2) Compare the t...

Embodiment 2

[0050](1) the parts material of the present embodiment is Cr12, read the tempering hardness-tempering temperature relational table in the database, as shown in table 1, the tempering hardness-tempering temperature relational table in the database is selected from Wang Xiankui, "Material and Its Heat Treatment", Machining Handbook (Single Book) ISBN 978-7-111-24249-9: Page 265, 2008.6.1.

[0051] (2) Determine the tempering temperature according to the tempering hardness requirement input by the user as HRC47-53, including:

[0052] 1) Standardized tempering hardness requirements: take the original tempering hardness range, that is, the intermediate value HRC50 of the tempering hardness requirements input by the user, as the standardized tempering hardness;

[0053] 2) Compare the tempering hardness after normalization with the tempering hardness upper limit and tempering hardness lower limit in the tempering hardness-tempering temperature relationship table in order to determi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com