Clamping device

A clamping device and clamping piece technology, applied in the direction of chucks, manipulators, manufacturing tools, etc., can solve the problems of large size, uncompact structure, and large space occupation of the clamping device, so as to reduce the size and achieve sufficient structure. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

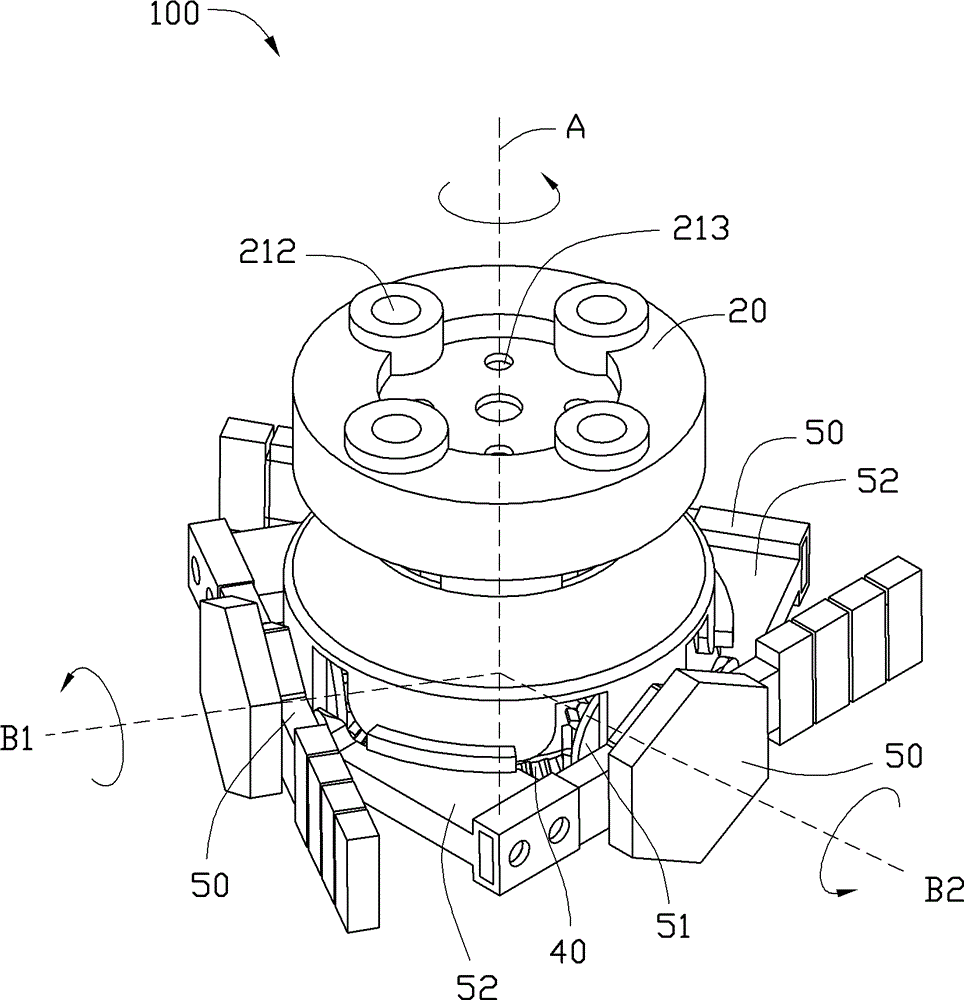

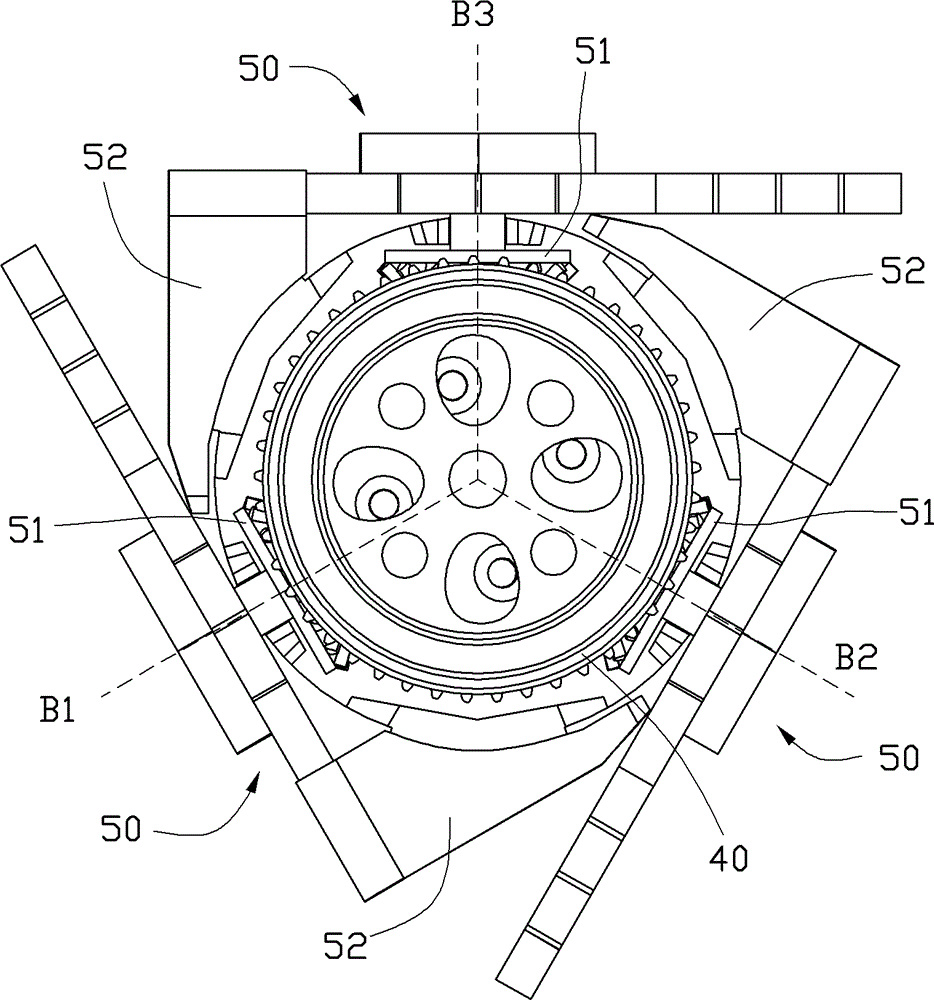

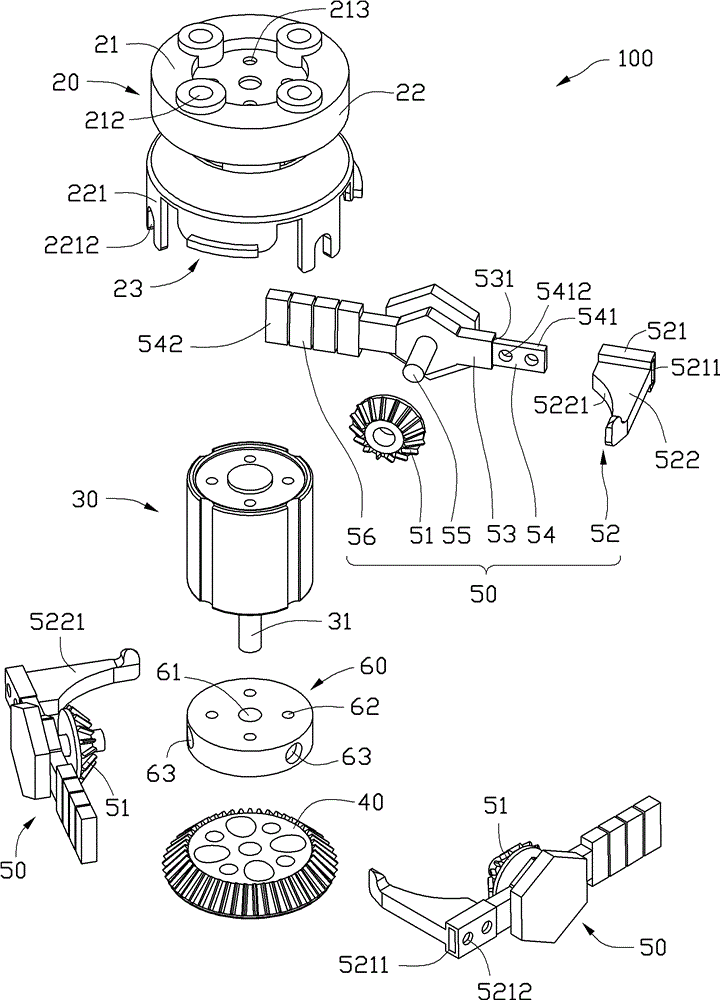

[0013] see Figure 1 to Figure 3 , The clamping device 100 according to the embodiment of the present invention includes a mounting base body 20 , a rotating driving member 30 disposed on the mounting base body 20 , a driving bevel gear 40 driven by the rotating driving member 30 and three clamping jaw assemblies 50 .

[0014] Each jaw assembly 50 includes a driven bevel gear 51 meshing with the driving bevel gear 40 and a clamping member 52 driven by the driven bevel gear 51 . The three jaw assemblies 50 surround the mounting base body 20 and are arranged at equal intervals in the circumferential direction. When the rotary driving member 30 drives the driving bevel gear 40 to rotate, the driven bevel gear 51 rotates accordingly, so that the clamping member 52 is relatively closed or opened to clamp or loosen the workpiece to be clamped.

[0015] In this embodiment, the driving bevel gear 40 rotates around the axis A, and the three driven bevel gears 51 respectively rotate ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com