Air compressor, and flow control method for an air compressor

A technology of gas compressors and control components, which is applied in pump control, machine/engine, liquid fuel engine, etc. It can solve the problems of inability to completely close the impeller outlet, stall and surge limitations, and expand the controllable maximum flow range , Ease of making and assembling parts, and simplifying the structure of the mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings, so that those skilled in the art can easily implement them. The present invention can be implemented in various forms, and is not limited to the following examples.

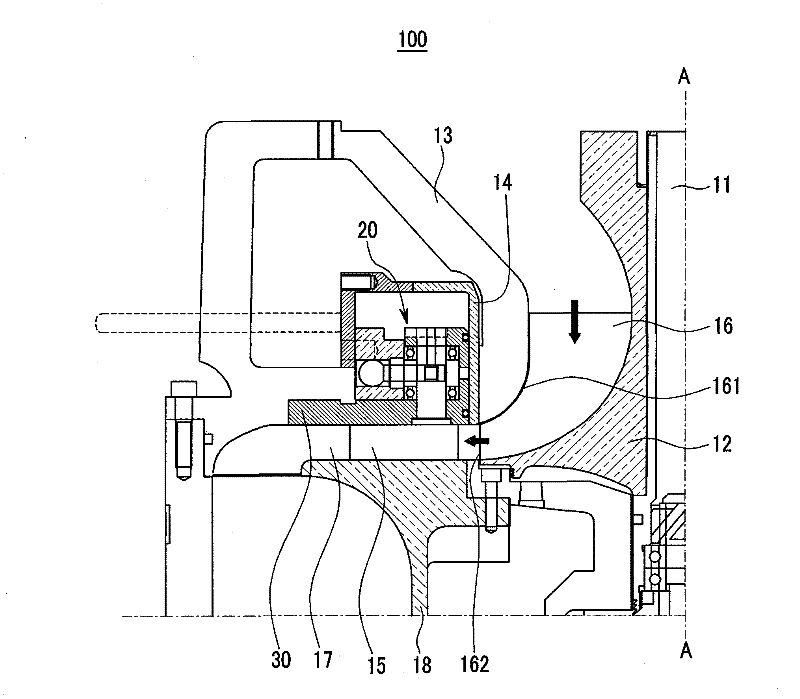

[0058] figure 1 is a partial sectional view of the gas compressor 100 according to the first embodiment of the present invention.

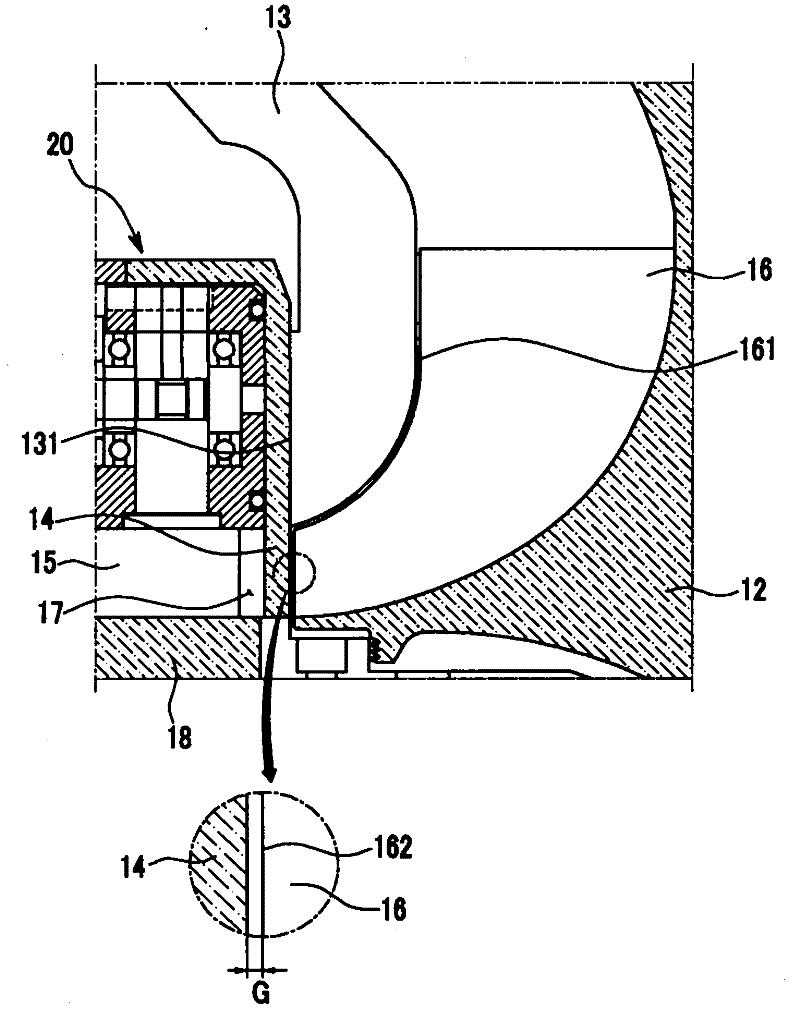

[0059] Please refer to figure 1 , the gas compressor 100 of the first embodiment includes: a rotating shaft 11, an impeller 12, a shroud 13, an annular valve 14, a plurality of vanes 15 ( figure 1 One fin is shown in ) and actuator 20. figure 1 The gas compressor 100 shown is bilaterally symmetrical with respect to the center line (A-A line) of the rotary shaft 11 .

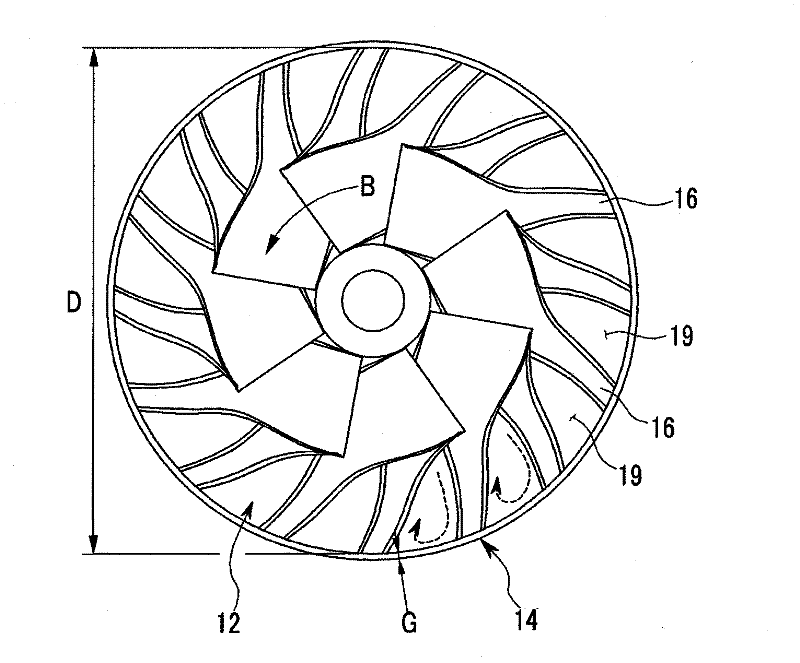

[0060] The impeller 12 is fixed to the rotary shaft 11, and the rotary shaft 11 is coupled to a not-shown motor rotary shaft. A plurality of curved and radial blades 16 are formed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com