Novel structure of convection heating surface of corner tube hot-water boiler

A hot water boiler and heating surface technology, applied in fluid heaters, lighting and heating equipment, etc., can solve problems such as uneven flow rate, avoid sudden changes in cross-section, prevent serious deposition, and save heating surface materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

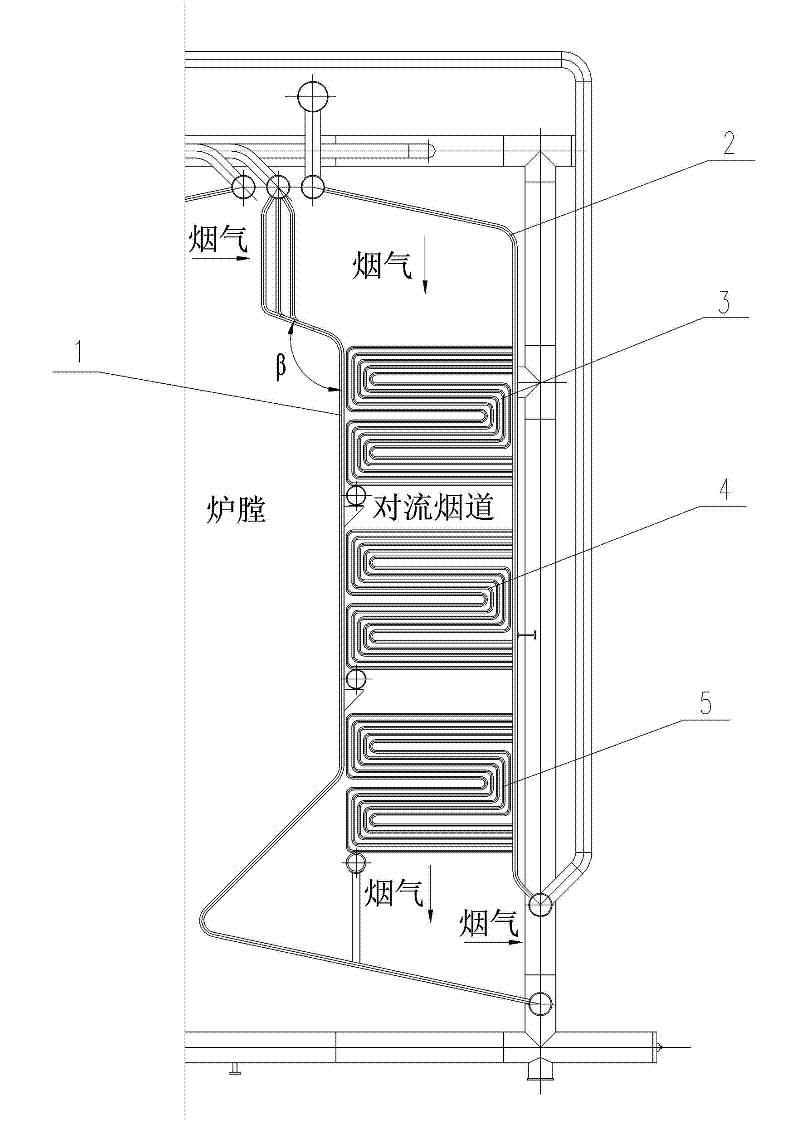

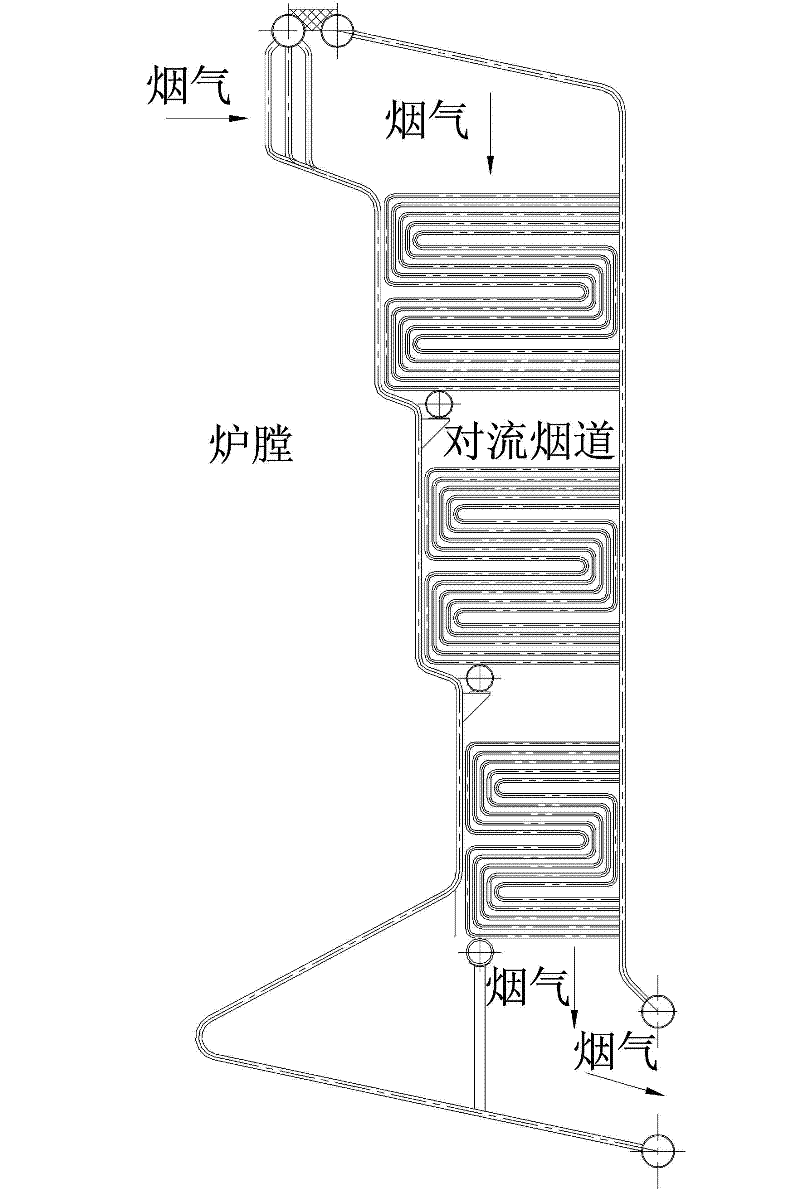

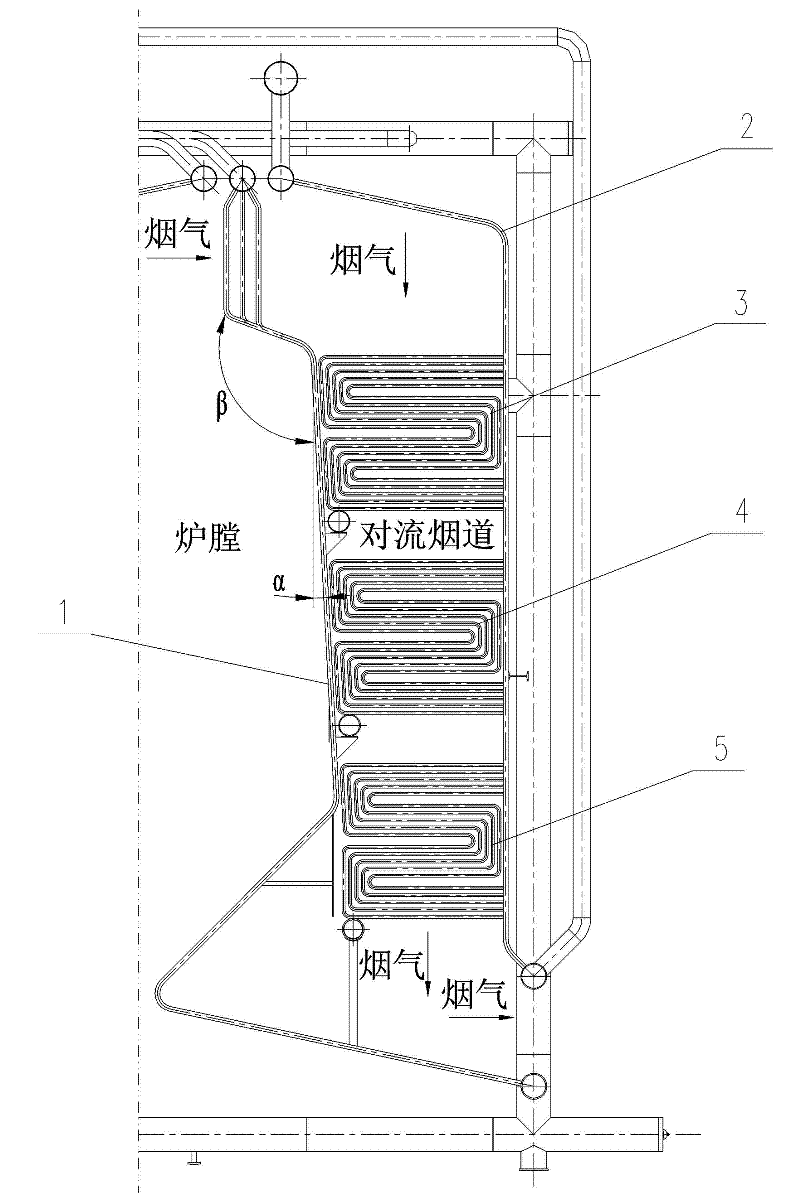

[0024] Such as image 3 Shown: the structure of the convection heating surface of a new type of corner tube hot water boiler of the present invention includes a furnace rear wall 1, a channel rear wall 2, a first-stage flag-type heating surface 3, a second-stage flag-type heating surface 4, The third-stage flag-type heating surface 5 is characterized in that the rear wall of the furnace is simply inclined at an angle α, so that the flue gas flow cross-sectional area of each level of convection heating surface in the convection flue is steadily reduced, so as to realize the flag-type heating of each level in the convection flue. The smoke velocity on the heating surface tends to be consistent. In the specific construction, it is only necessary to add an angle α to the original bending angle β when bending the membrane wall of the rear wall of the furnace. The rest of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com