Integrated hydroprocessing method

A technology for hydrotreating and treating zone, applied in hydrotreating process, treating hydrocarbon oil, petroleum industry, etc., can solve the problems of complicated operation, low total income, high energy consumption and material consumption, etc., to simplify the process flow, reduce The effect of low total consumption and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

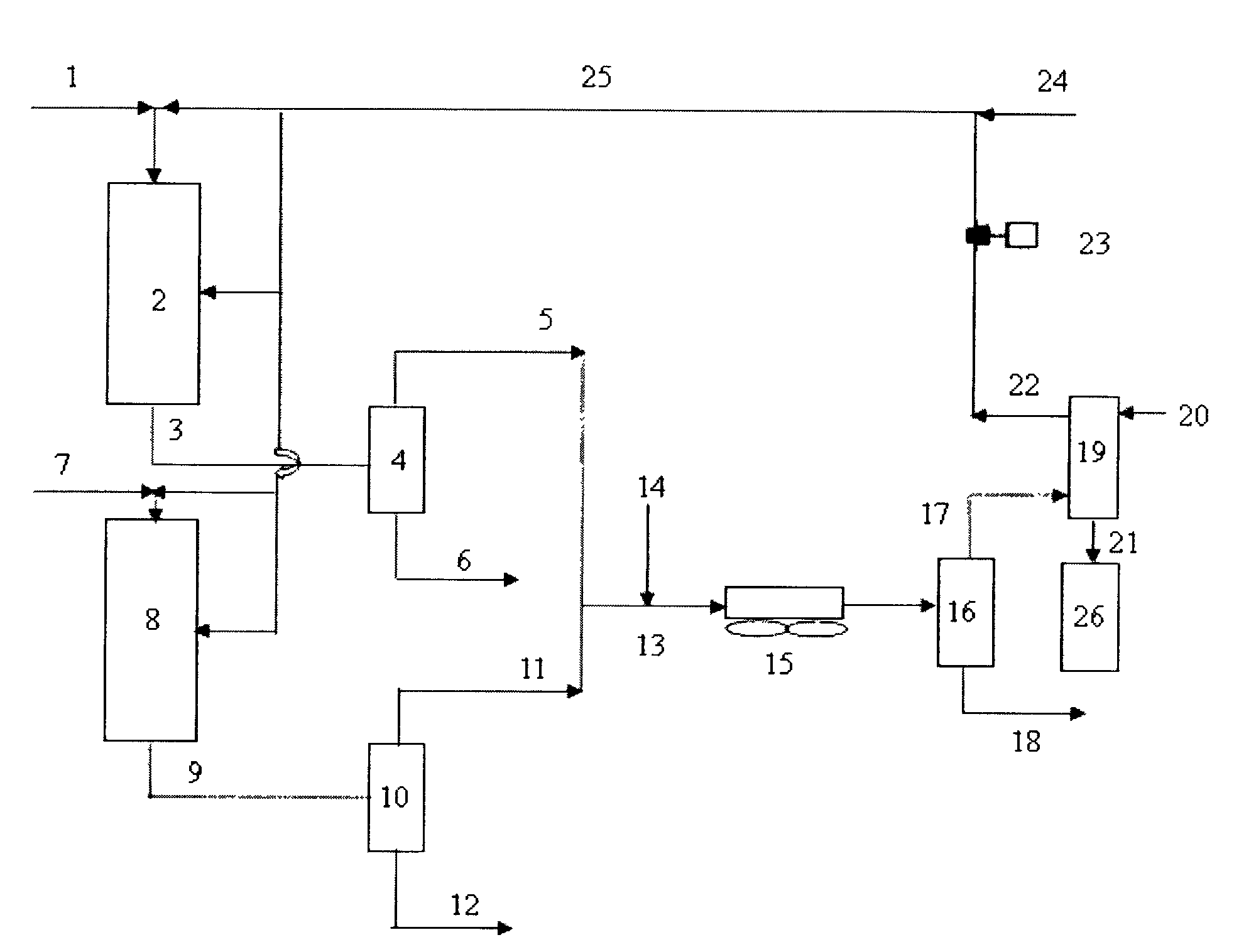

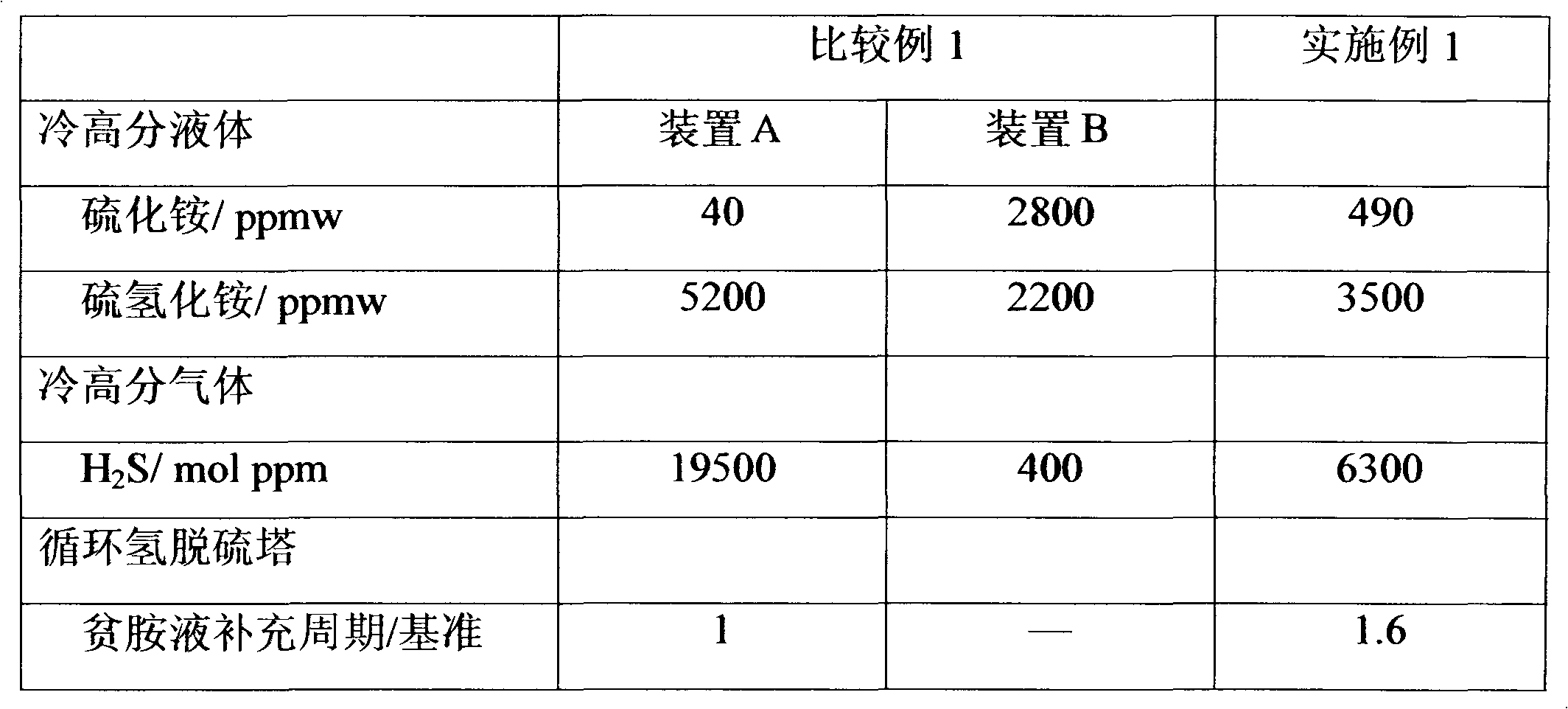

[0030] use figure 1 In the process flow shown, the circulating hydrogen paths of hydrotreating units A and B are organically combined. The properties of the catalysts used in the examples are listed in Table 1. The catalyst is a commercial catalyst developed and produced by Fushun Petrochemical Research Institute.

[0031] The properties of raw oil are shown in Table 2, the operating conditions of hydrotreating are shown in Table 3, and the gas composition and the replenishment period of lean amine solution after mixing high-fraction gas with water are shown in Table 3.

[0032] Table 1 Main physicochemical properties of the catalyst

[0033] catalyst

FF-14

FF-46

Physical properties:

Pore volume, mL / g

0.341

>0.33

Specific surface, m 2 / g

167

>160

Packing density, g / cm 3

0.955

~0.90

Compressive strength, KN / grain

15.9

≥150

Chemical composition, wt%:

...

Embodiment approach

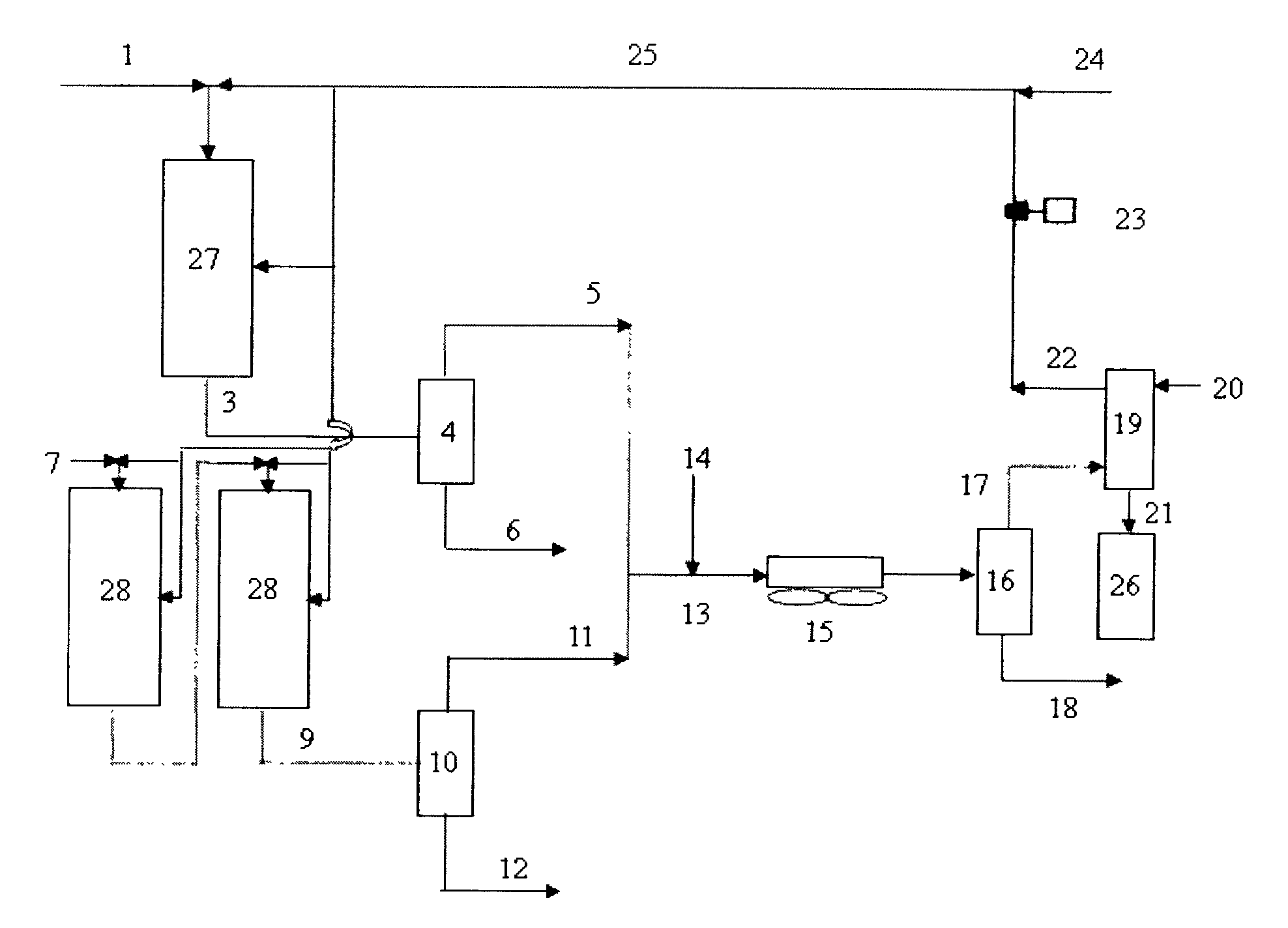

[0040] Such as figure 2 As shown, another embodiment of the combined hydroprocessing method of the present invention is as follows:

[0041] The high-sulfur diesel raw material 1 is mixed with hydrogen 25 and enters the hydrotreating unit 27, and the reaction effluent 3 enters the thermal high-pressure separator 4 (referred to as thermal high-resolution), and the liquid 6 obtained by the thermal high-resolution is sent to the fractionation tower; the high-nitrogen raw material 7 is mixed with After the hydrogen gas 25 is mixed, it enters the hydrocracking unit 28, and the obtained reaction effluent 9 enters the heat fraction 10 for separation, and the obtained liquid 12 goes to the fractionation tower; the gas 5 obtained from the heat fraction 4 is mixed with the gas 11 obtained from the heat fraction 10 Afterwards, gas 13 is formed, and the gas 13 is injected into the washing water 14. After passing through the high-pressure air cooler 15, it enters the cold high-pressure se...

Embodiment 2

[0046] use figure 2 In the process flow shown, the circulating hydrogen paths of the hydrorefining unit A and the hydrocracking unit B are organically combined. The properties of the catalysts used in the examples are listed in Table 5. The catalyst is a commercial catalyst developed and produced by Fushun Petrochemical Research Institute.

[0047] The properties of raw oil are shown in Table 6, the operating conditions of hydrotreating are shown in Table 7, and the gas composition after mixing high-fraction gas and washing with water and the replenishment cycle of lean amine solution are shown in Table 8.

[0048] Table 5 Main Physicochemical Properties of Catalysts

[0049] project

FF-36

FC-14

Appearance shape

Clover Strips

Cylindrical bar

Particle diameter, mm

1.1~1.3

1.5~1.7

Strip length, mm

3~8

3~8

Crushing strength, N / cm

≥180

>185

Chemical composition, m%:

M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com