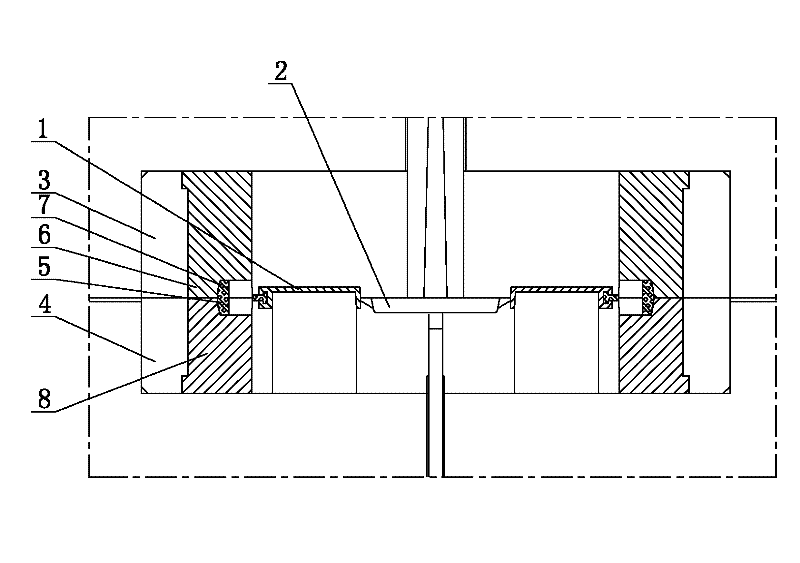

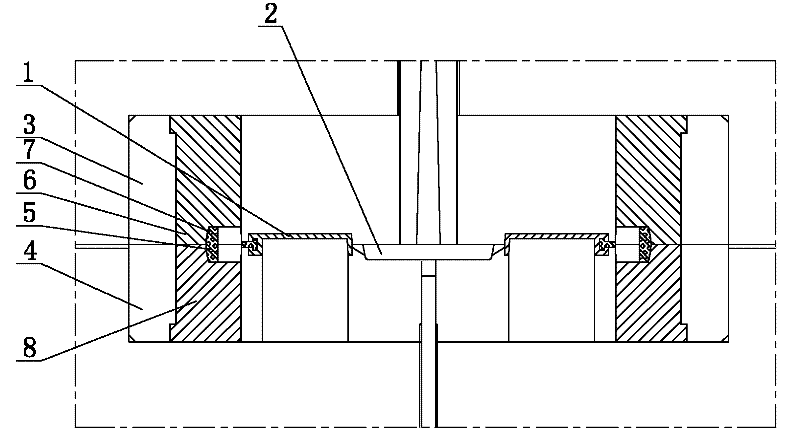

Structure of protecting appearances of metal inserts in mould

A technology of metal inserts and appearance, applied in the direction of coating, etc., can solve the problems of high cost, surface strain of metal inserts, mold core strain, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] See figure 1 , which includes product cavity 1, runner 2, front mold core 3, rear mold core 4, metal insert 5, flow channel 2 connected to product cavity, metal insert 5 connected to product cavity 1, and metal insert 5 outside An engineering plastic sleeve is installed between the surface and the inner surface of the front mold core 3 and the rear mold core 4, the outer surface of the metal insert 5 fits the installation groove 7 on the inner surface of the engineering plastic sleeve, and the outer surface of the engineering plastic sleeve The surface fits the inner surfaces of the front mold core 3 and the rear mold core 4. The engineering plastics sleeve is formed by joining the upper sleeve 6 and the lower sleeve 8, and the installation groove 7 on the inner surface is formed by joining the upper sleeve 6 and the lower sleeve 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com