Switching mechanism used in car roof die

A switching mechanism and roof cover technology, which is applied in the field of auto parts processing, can solve the problems of time-consuming and labor-intensive, increase the workload of maintenance personnel, increase human errors, etc., to reduce the probability of human errors, shorten production switching time, The effect of avoiding work equipment accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

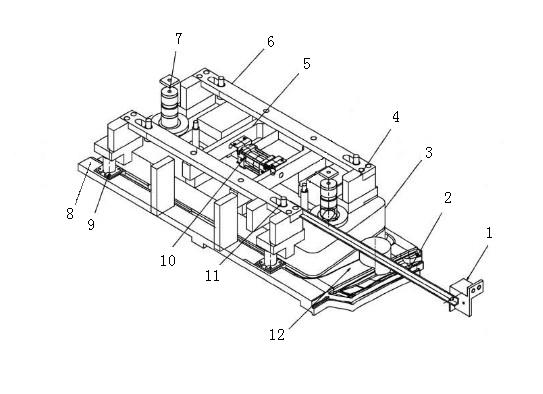

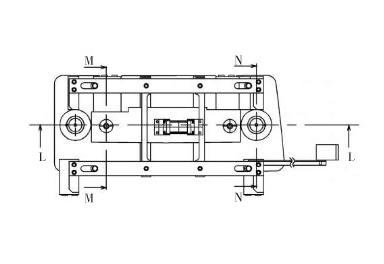

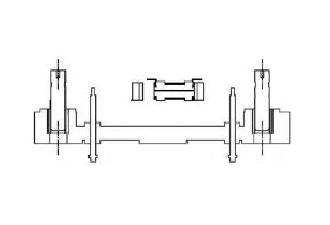

[0014] Such as Figure 1-5 As shown, the present invention includes a die 8, a base 3 fixed with a punch, and a mechanism group consisting of a support plate 5, a support plate 4, and a connecting plate 6. The support plate 5 is located in the middle of the base 3, and the support plate 4 is located in the middle of the base 3. On both sides of the base 3, the connecting plate 6 connects the supporting plate 5 and the supporting plate 4 as a whole, the working screw 11 on the base 3 is installed in the connecting plate 6, and the mechanism group is connected with a cylinder 10, and the activity of the cylinder 10 The end is connected on the support plate 5, and after the cylinder 10 is subjected to the action of air, due to the action of the working screw 11, it can only pull the mechanism group to move left and right. A guide column and guide sleeve 7 is installed on the top, so that the base 3 can move vertically up and down. One end of the mechanism group is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com