Steaming boiler with built-in water container capable of generating steam quickly

A water container and steam technology, which is applied to heating devices, steam cooking utensils, etc., can solve the problems of wasting time and large heat energy consumption, and achieve the effect of obvious energy saving and shortening the time of steaming rice or vegetables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is further described below in conjunction with embodiment; The following embodiment is not for the limitation of the present invention, only as the mode of supporting the realization of the present invention, any equivalent structural replacement within the technical framework disclosed in the present invention, all is the present invention. the scope of protection of the invention;

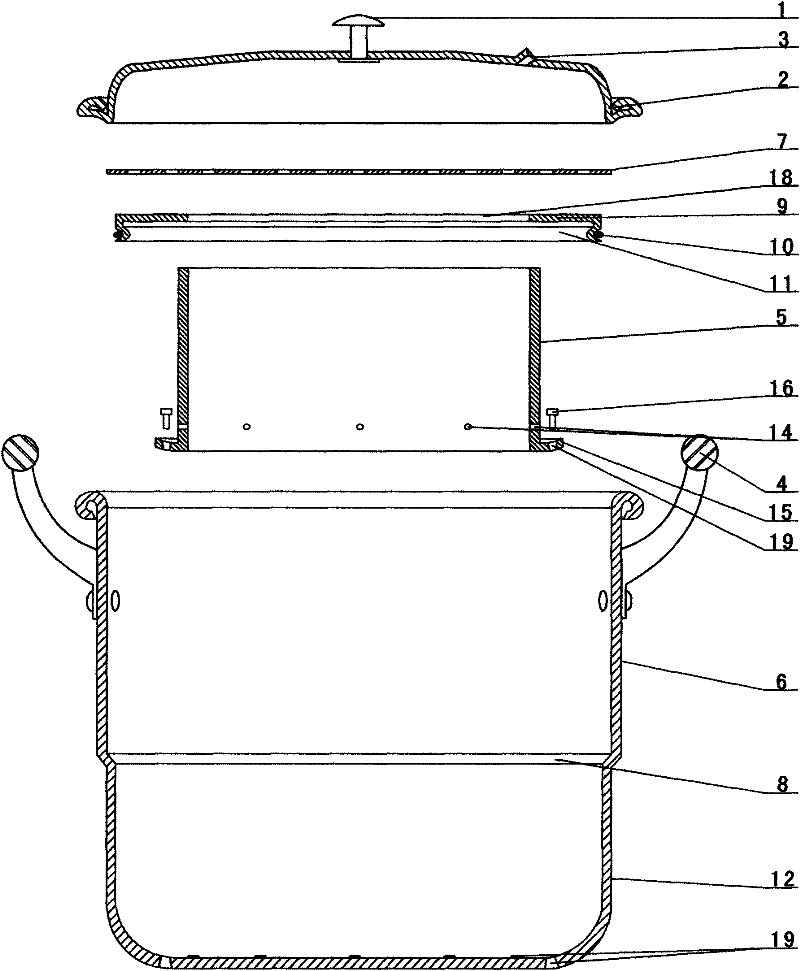

[0015] combined with figure 1 Or the steamer with the built-in water container described in 2 to quickly generate steam, comprising a pot cover 2, a pot body, a steamer grate 7 and an annular tube 5, the top of the pot cover 2 is provided with a pot cover handle 1, and the pot cover handle 1 is optional The pot cover 2 on one side is provided with a steam outlet 3; the upper pot body 6 of the pot body is provided with a pot body handle 4 respectively on both sides, and a step 8 is arranged in the middle of the pot body, and the steamer grate 7 is pressed on the step 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com