An automatic capping machine

A capping machine and automatic technology, applied in the direction of hand-held tools, manufacturing tools, etc., can solve the problems of low product qualification rate, low work efficiency, high labor intensity, etc., and achieve low labor intensity, high work efficiency, and high pass rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

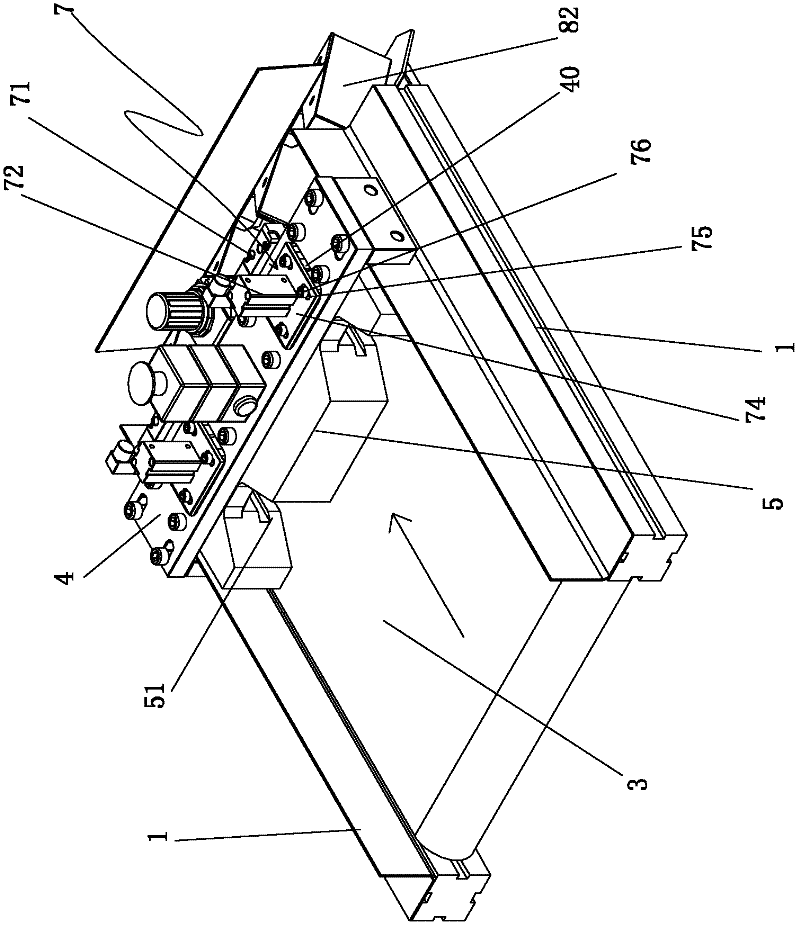

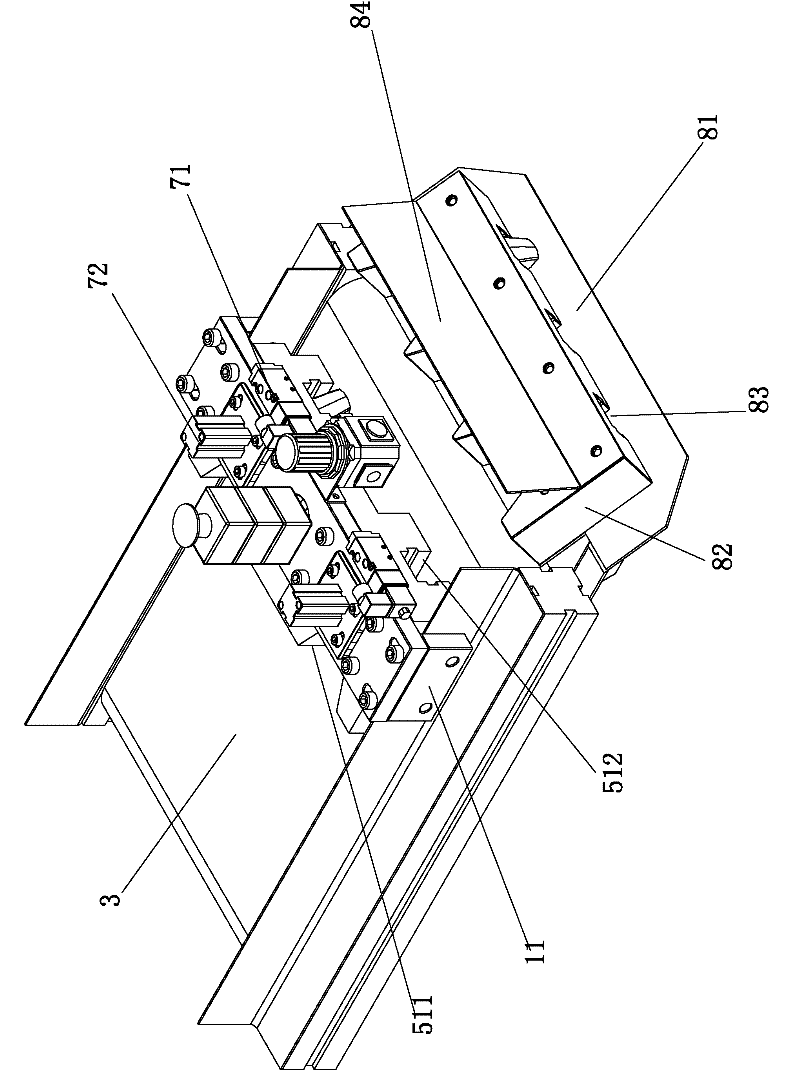

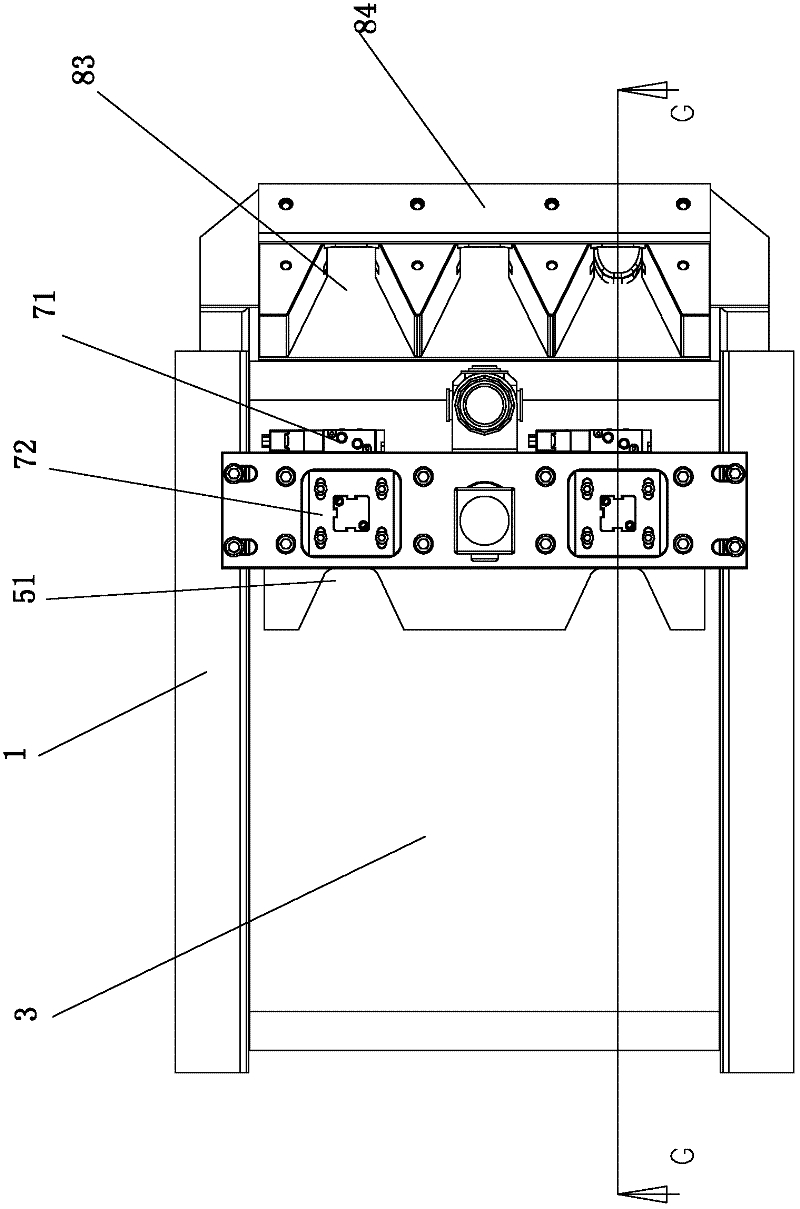

[0021] The present invention is an automatic capping machine, which includes two left and right wing plates 1 and a main controller 2, and a feeding belt 3 is installed between the two wing plates 1, and the feeding belt 3 is controlled by the main controller 2 to rotate to carry out To transport bottle caps, a transverse base plate 4 is fixed on the two wing plates 1. The transverse base plate 4 is located above and close to the feeding belt 3. At the bottom of the transverse base plate 4, there are two bottle caps arranged along the conveying direction of the feeding belt 3. The channel 51 is equipped with a detection device 6 in the bottle cap channel 51. When a bottle cap passes through, the detection device 6 will detect and send the detection signal to the main controller 2. A capping device 7 is provided on the transverse substrate 4. After the main controller 2 receives the signal from the detection device 6 , it immediately controls the capping device 7 to extend downw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com