Circulating pipe network water quality integrative simulation test system

A simulation test system and circulation pipe technology, applied in the field of water quality comprehensive simulation test system of circulation pipe network, can solve problems such as difficult to study working conditions and internal habitat, influence on circulation water quality, and inability to simulate pressurized operating environment of main water supply pipe network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

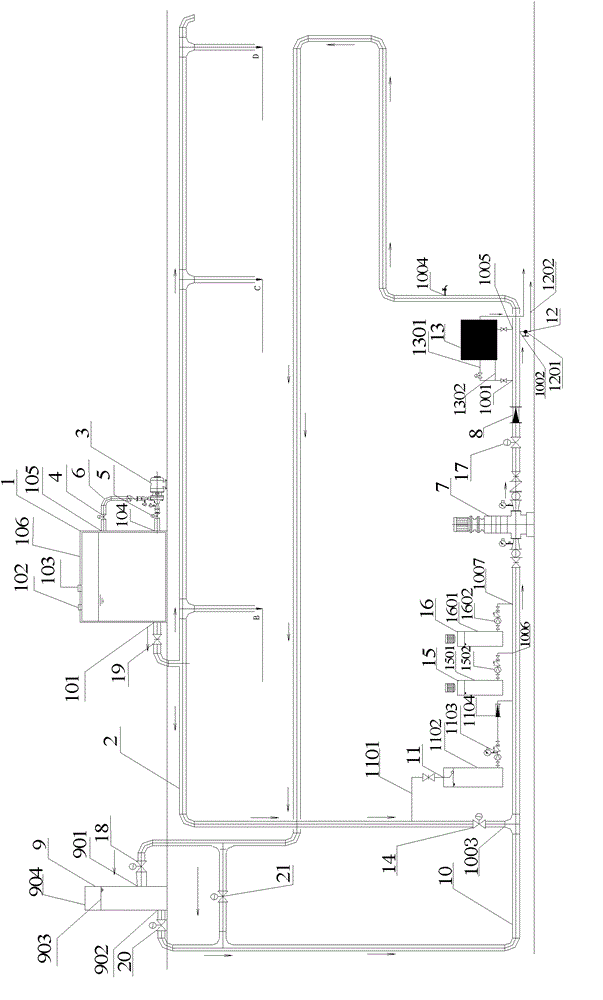

[0040] like figure 1 As shown, the circulation pipe network water quality comprehensive simulation test system of the present invention consists of 1 water supply subsystem and 4 independent circulation pipe network subsystems connected to the water supply subsystem by the pipeline 2 (hereinafter referred to as pipeline 2) of the water supply subsystem.

[0041] The water supply subsystem includes a water supply tank 1, a pipeline 2, a mixing circulation pump 3, a valve 4, a valve 5, a valve 19 and a pipeline 6. The water supply tank 1 is cylindrical and has a volume of 6000L. The water supply tank 1 includes a water outlet 101 of the water supply tank 1 , the water inlet 102 of the water supply tank 1, the medicament injection port 103 of the water supply tank 1, the outlet 104 of the water supply tank 1, the inlet 105 of the water supply tank 1 and the dustproof cover 106 of the water supply tank, the water outlet 101 of the water supply tank 1 is located near the water supply ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com