A fault detection method for cage-type asynchronous motor rotor broken bars based on esprit and psa

An asynchronous motor and rotor broken bar technology, applied in the field of detection, can solve problems such as failure, deterioration of rotor broken bar fault detection performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

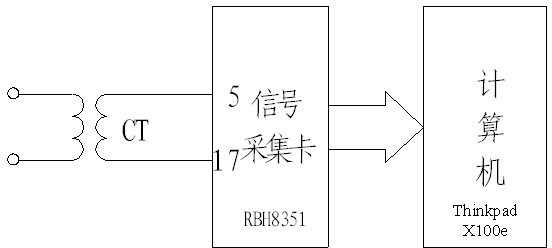

[0086] The present invention adopts image 3 The circuit shown is for detection. The circuit is composed of a current transformer CT, a signal acquisition card and a portable computer. The current transformer is connected to a phase line of the stator winding of an asynchronous motor, and its signal output terminal is connected to the analog signal of the signal acquisition card. Input channel 5 (input terminals 5 and 17), the output port of the signal acquisition card is connected to the USB port of the portable computer. The signal acquisition card adopts Ruibohua RBH8351 signal acquisition card, and the model of the portable computer is Thinkpad X100e. The signal acquisition card integrates low-pass filter, signal acquisition and hold, analog / digital conversion and other circuits. The instantaneous stator current signal is sent to the signal acquisition card, and the signal acquisition card is connected to the portable computer through the USB interface. The portable compu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com