A coal seam hydraulic fracturing simulation experiment method

A technology for hydraulic fracturing and simulation experiments, which is applied in the direction of applying stable tension/pressure to test the strength of materials, which can solve the problems of difficult to identify small hydraulic fractures, difficult to distinguish between natural fractures and hydraulic fractures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

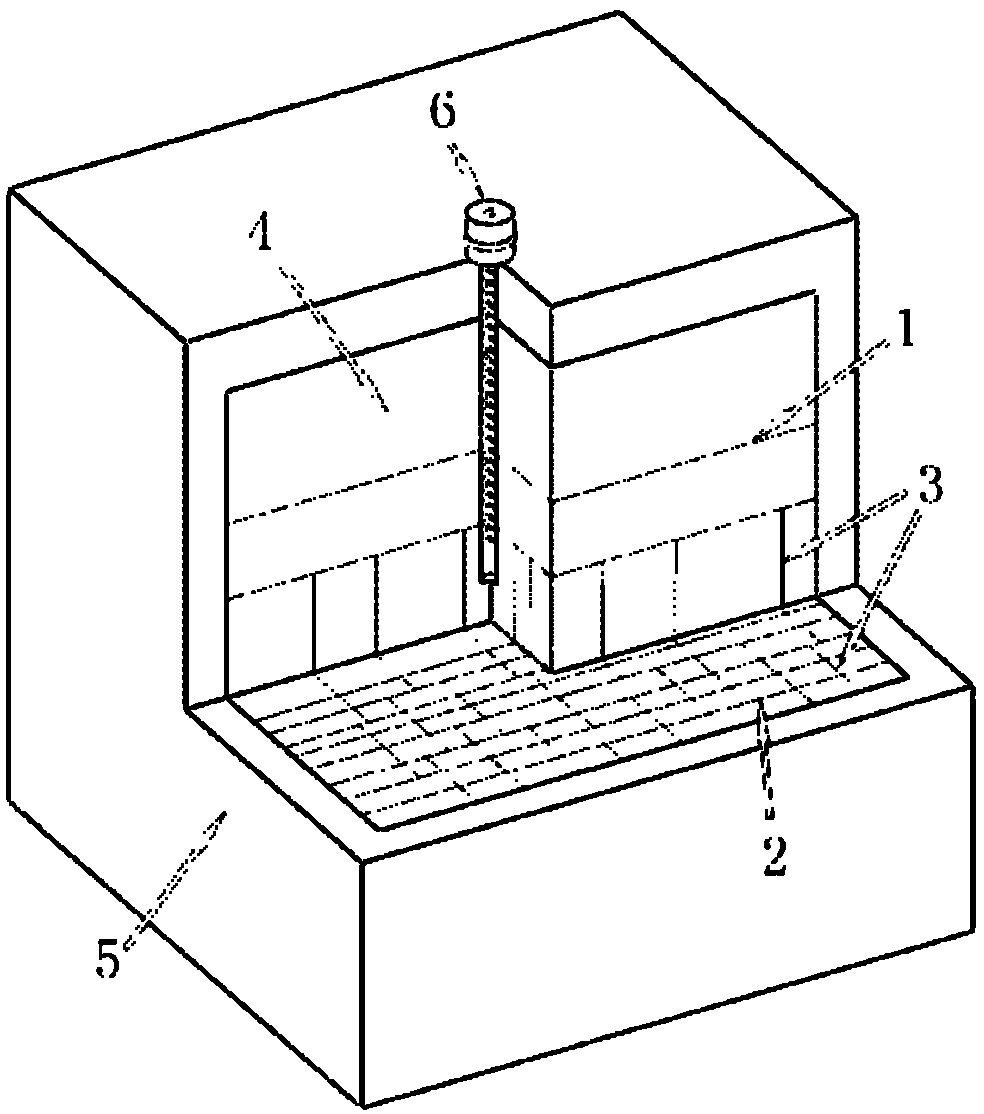

[0020] In order to make the objectives, technical solutions, and advantages of the embodiments of the present invention clearer, the following further describes the embodiments of the present invention in detail with reference to the accompanying drawings. Here, the illustrative embodiments of the present invention and the description thereof are used to explain the present invention, but not as a limitation to the present invention.

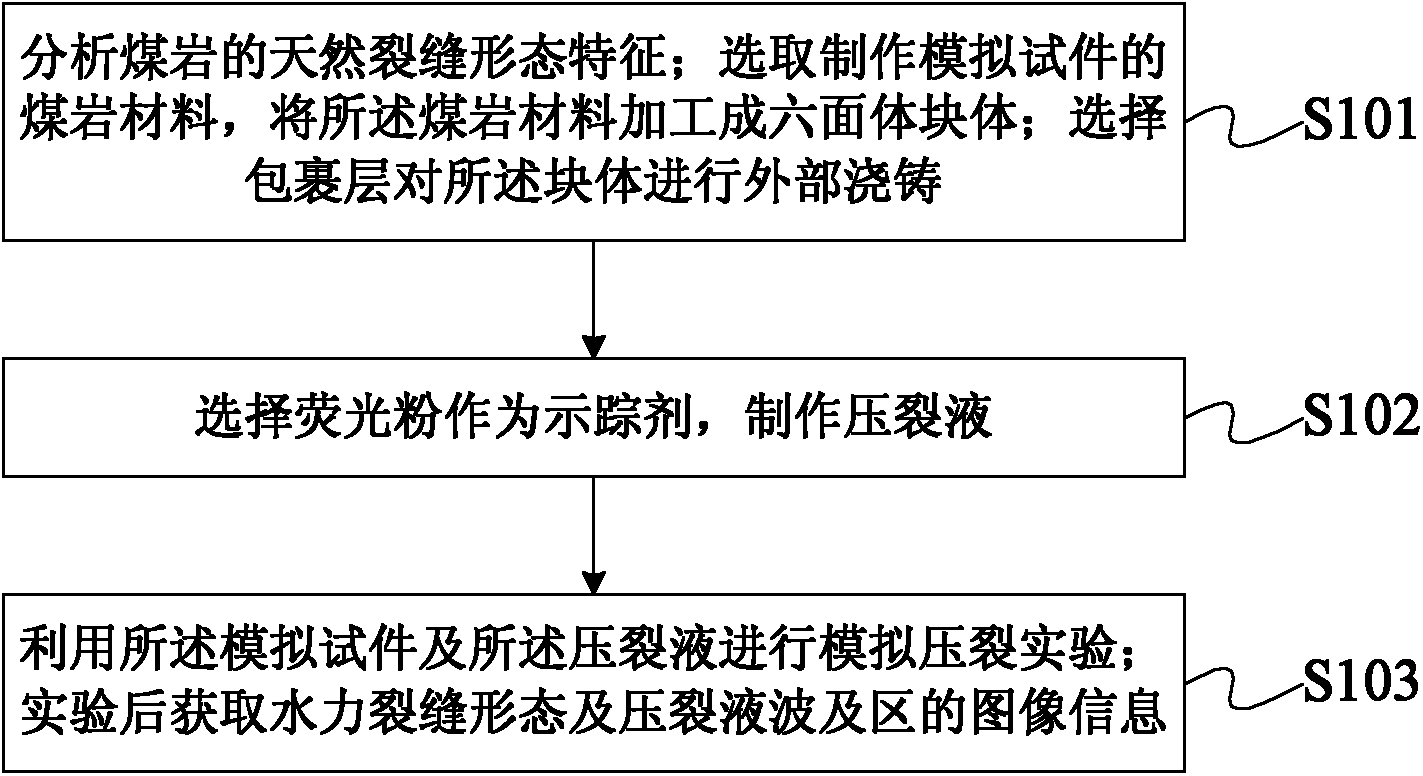

[0021] In order to perform hydraulic fracturing simulation experiments on coal seams, and to observe the shape and geometric size of hydraulic fractures more effectively in the experiments, and overcome the shortcomings of the prior art in distinguishing hydraulic fractures from natural fractures and displaying micro-cracks, the present invention provides a coal seam Hydraulic fracturing test methods, such as figure 1 As shown, the method includes the following steps:

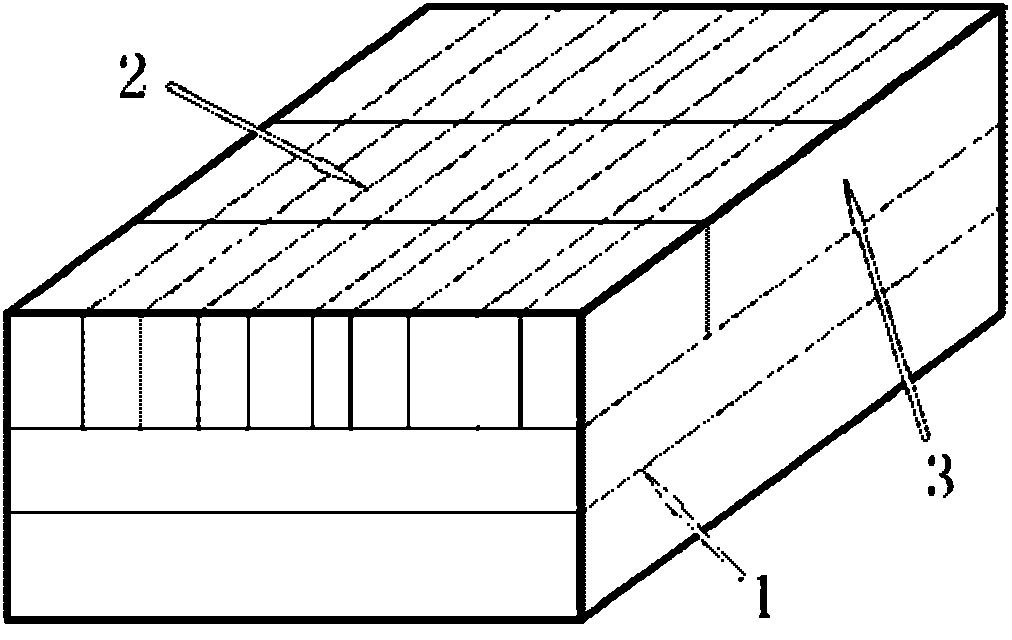

[0022] Step S101: Analyze the natural fracture morphology characteristics of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com