An inner support body of a safety tire

An inner support, safety tire technology, applied in tire parts, transportation and packaging, vehicle parts, etc., can solve the problems of not finding the inner support, damage to the wheel rim, uncontrolled overturning, etc., to solve the problem of high temperature heat dissipation , cost saving, and the effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

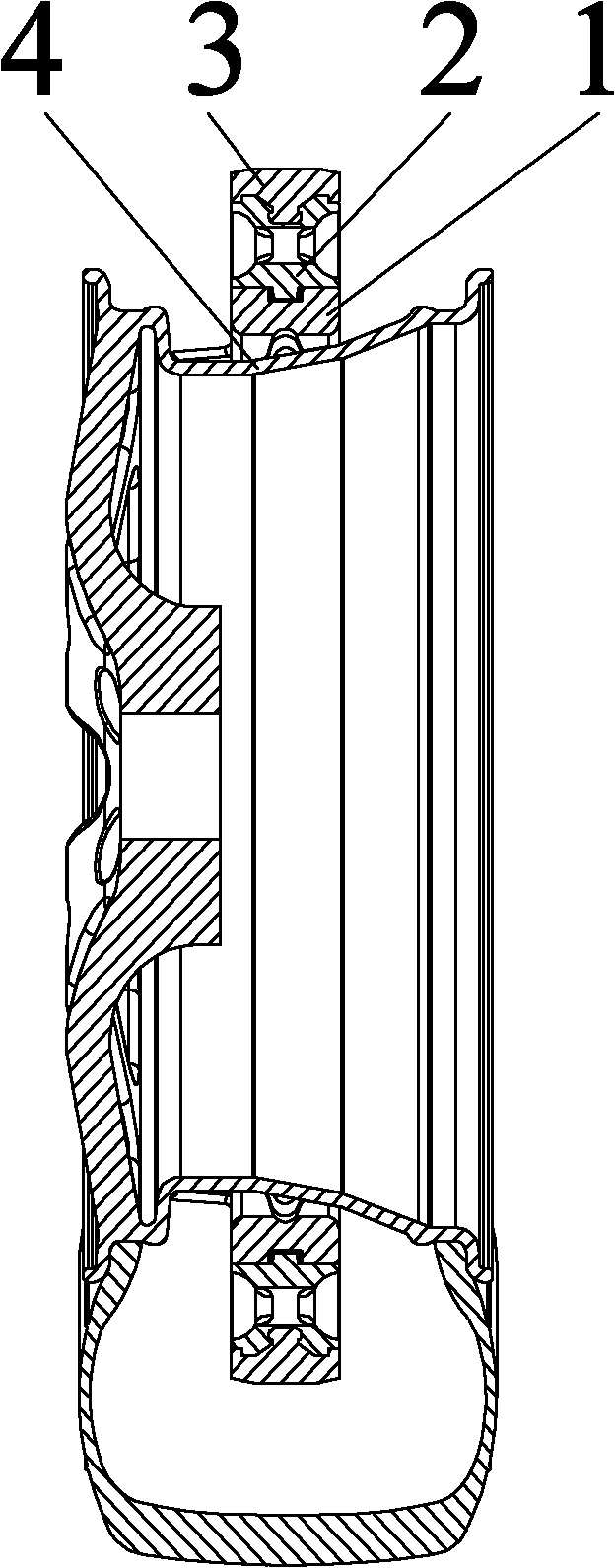

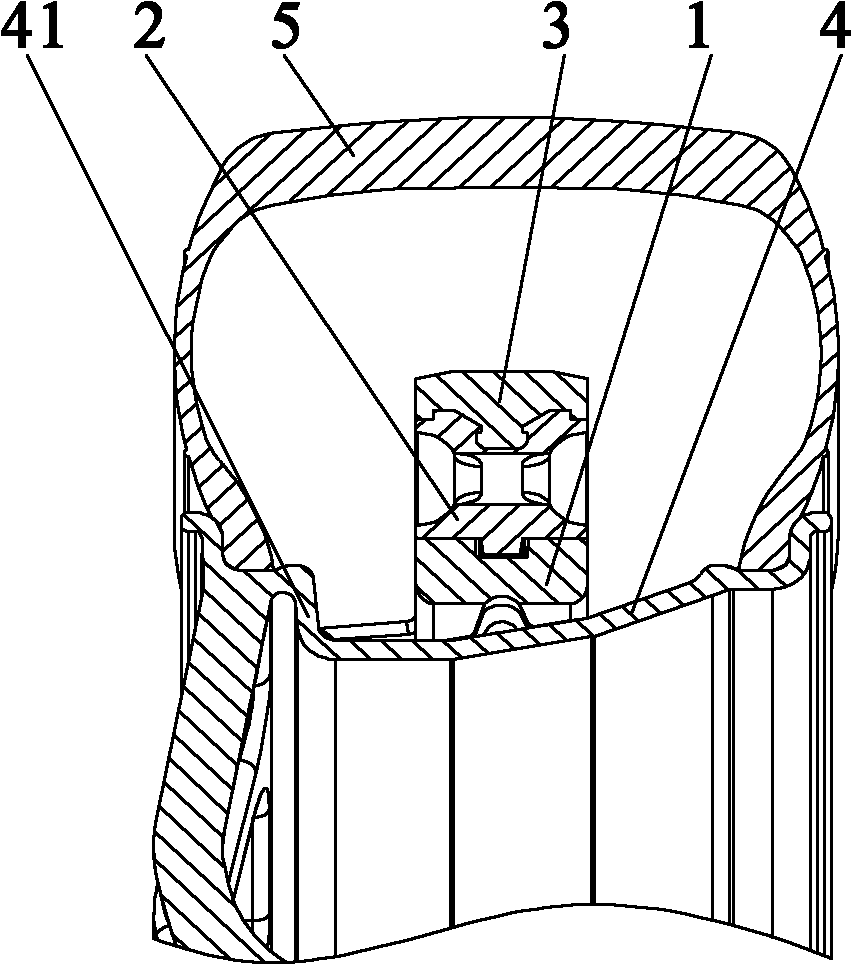

[0029] Such as Figures 1 to 10 As shown, the inner support body of the safety tire of the present invention includes an inner ring 1, a metal ring 2 and a buffer ring 3 arranged sequentially from the hub steel rim toward the outer tire direction, and the inner ring surface of the inner ring 1 is fitted with a rim pattern. Surface 11, which surrounds the rim pattern of the wheel hub steel ring 4, the outer ring surface of the inner ring 1 is the metal ring matching surface 12, the inner ring surface of the metal ring 2 surrounds the metal ring matching surface 12 of the inner ring, and the metal ring The outer ring surface of the buffer ring 2 is provided with a buffer ring installation groove 21 and a buffer ring limit groove 22, and the inner ring surface of the buffer ring 3 is provided with a limit rib 31 and a limit platform 32, and the limit rib 31 is correspondingly embedded in the metal ring 2 In the buffer ring installation groove 21 of the outer annulus of the metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com