Palm hammer nailing depth adjustment mechanism

A technology of depth adjustment and palm hammer, which is applied in the direction of nailing tools and manufacturing tools, can solve the problems of small control panel and cannot meet actual needs, and achieve the effect of compact structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

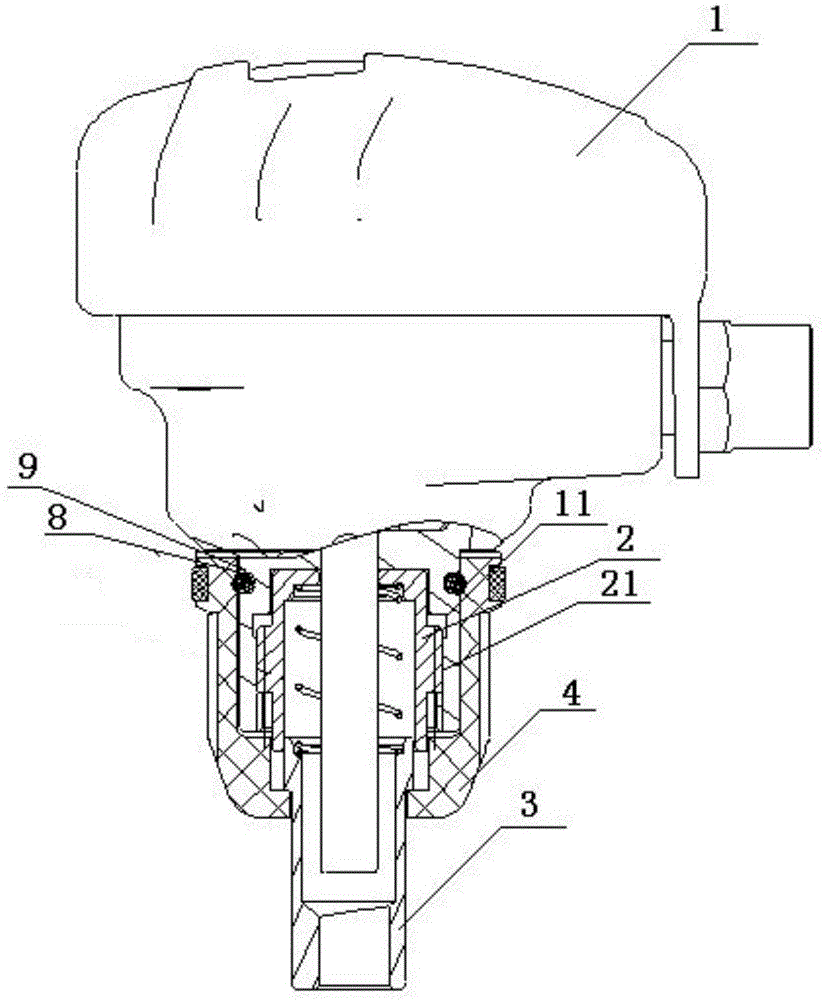

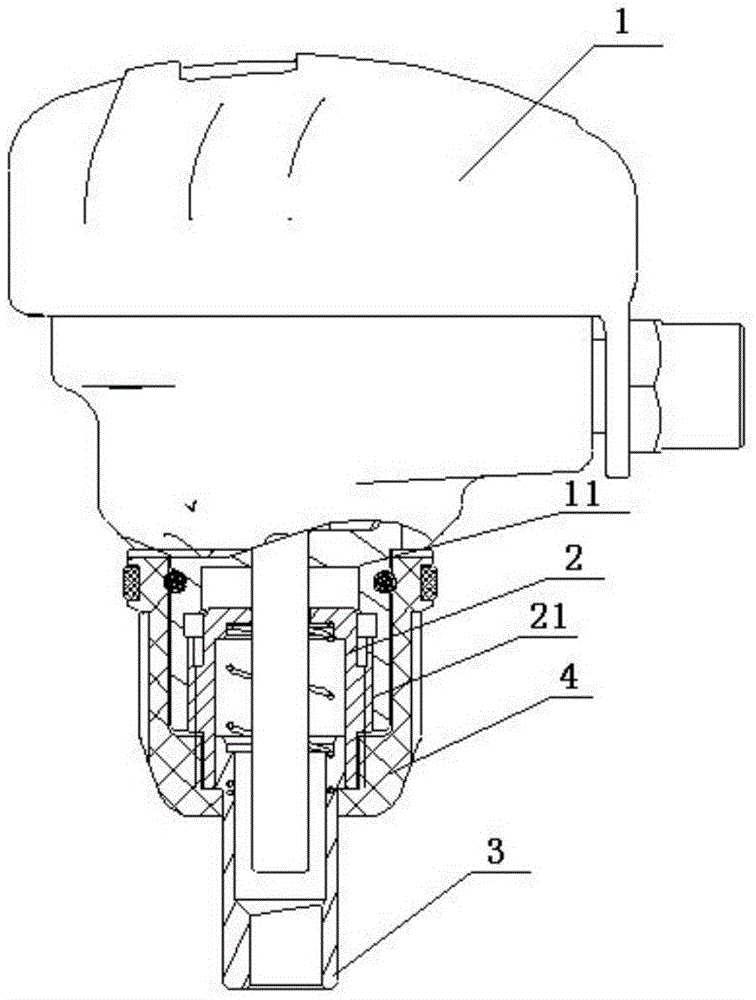

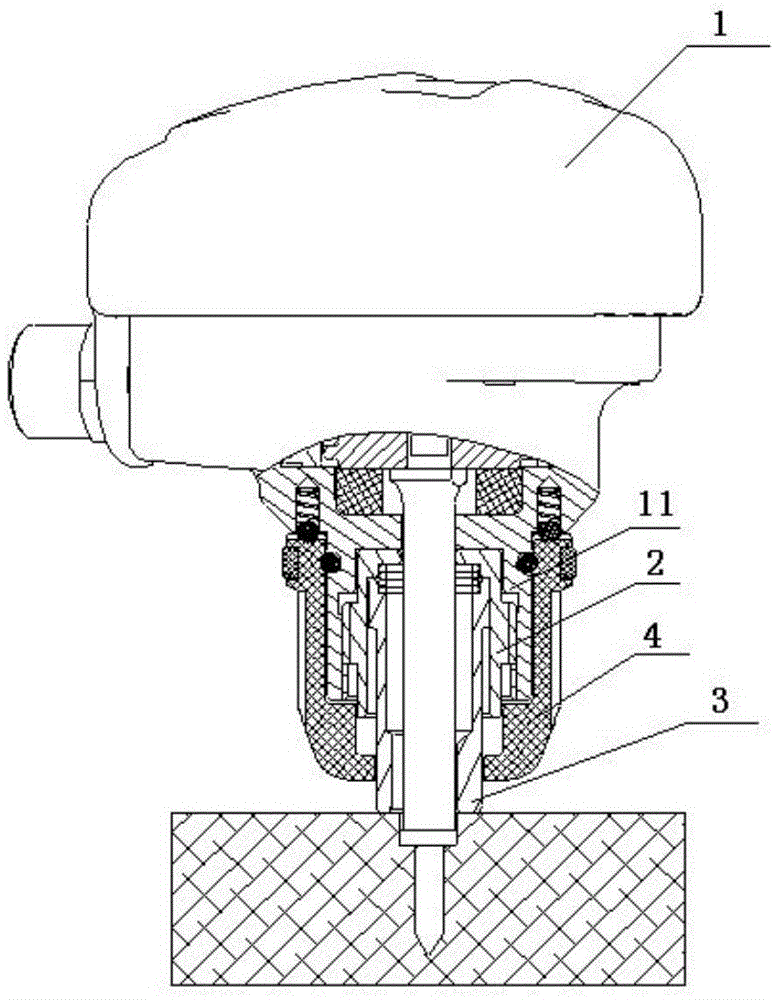

[0017] Referring to the attached picture:

[0018] The palm hammer nailing depth adjustment mechanism of the present invention includes a hammer body 1, a guide sleeve 3, and an adjustment seat 4. The cylindrical body 11 below the hammer body 1 is connected to the pin 8 through a horizontal annular groove 12 for adjustment. Seat 4, the contact position between the adjusting seat 4 and the hammer body 1 is provided with a rotating gear mechanism, and the rotating gear mechanism includes a top ball 6 provided with a spring 5, and the top ball 6 cooperates with the pit 41 to form an adjustment The rotation gear of the seat 4; the guide sleeve 3 used to cover around the nail, the lower end of the guide sleeve 3 passes through the bottom of the adjustment seat 4; the striker used to hit the nail, the striker along the guide The axis line of cover 3 and adjustment seat 4 strikes the nail, and the inner surface of cylinder 11 below the hammer body 1 is threaded with a screw sleeve 2;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com