Alignment stage

A technology of alignment table and table top, applied in the field of alignment table, can solve problems such as thermal deformation and position deviation, and achieve the effect of improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

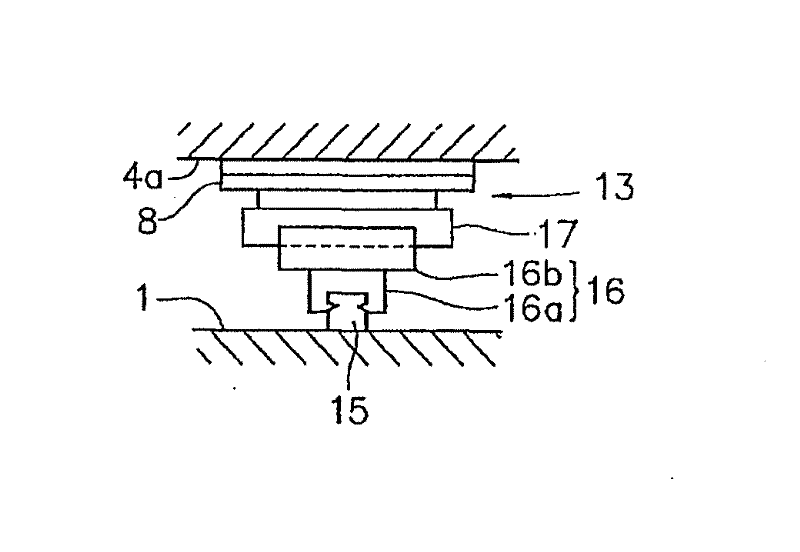

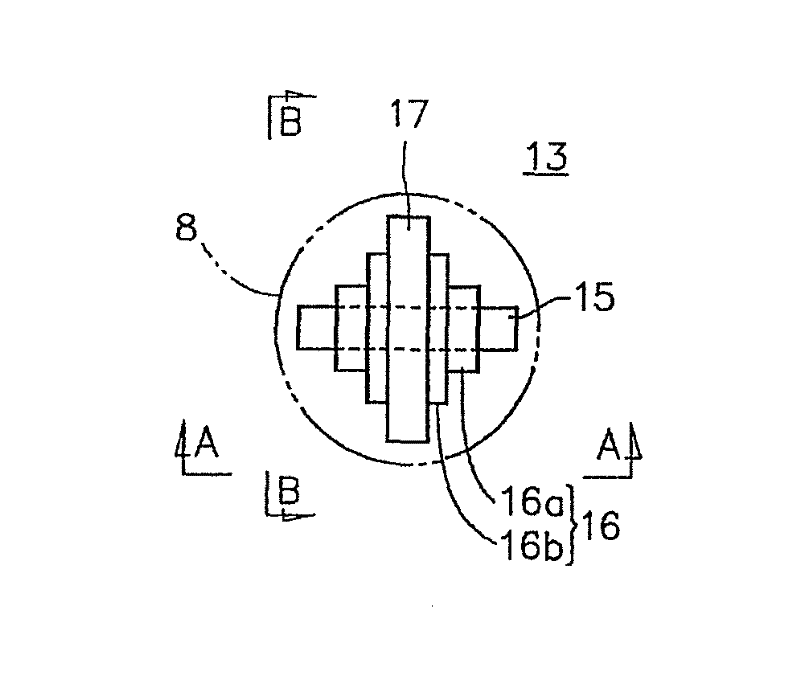

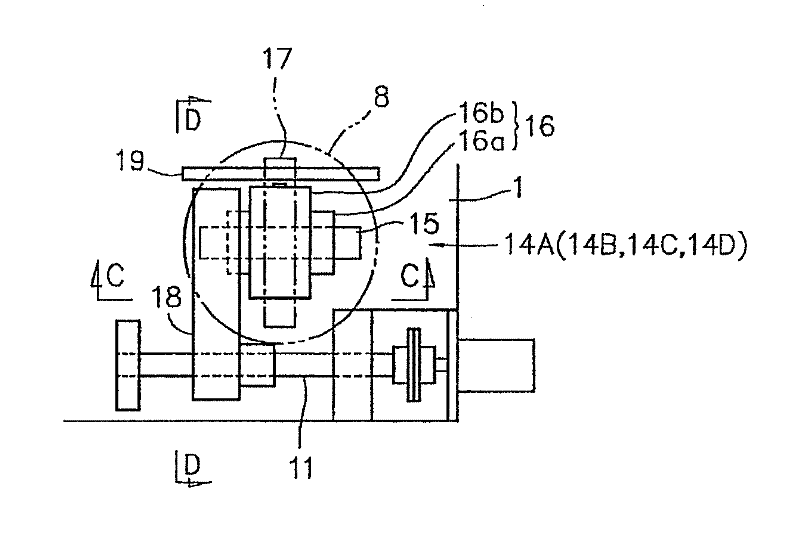

[0073] Hereinafter, embodiments for carrying out the present invention will be described with reference to the drawings.

[0074] exist Figure 1 to Figure 5 One embodiment of the alignment stage of this invention is shown in .

[0075] The table top 4a is arranged above the required size of the base 1 as the fixed side. The table top 4 a holds a workpiece (not shown) to which a moving load acts, for example, a plate or a printing object to which a moving load acts by moving a rotating squeegee while pushing against it during offset printing. Between the above-mentioned base 1 and the table 4a, the moving direction of the moving load (hereinafter referred to simply as the load moving direction) acting on the workpiece not shown in the above-mentioned figure is indicated by an arrow L in the figure. Image 6 , Figure 7 The same is true in ) where the required parts are arranged in a staggered manner, for example, from the upstream side of the load moving direction L, in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com