An electronically controlled reversing valve

A reversing valve, electronic control technology, applied in valve details, multi-port valves, valve devices, etc., can solve the problems of reversing valve failure, easy inhalation, piston cavity blockage, etc., to achieve low power consumption, good sealing performance, The effect of improving service life and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] specific implementation plan

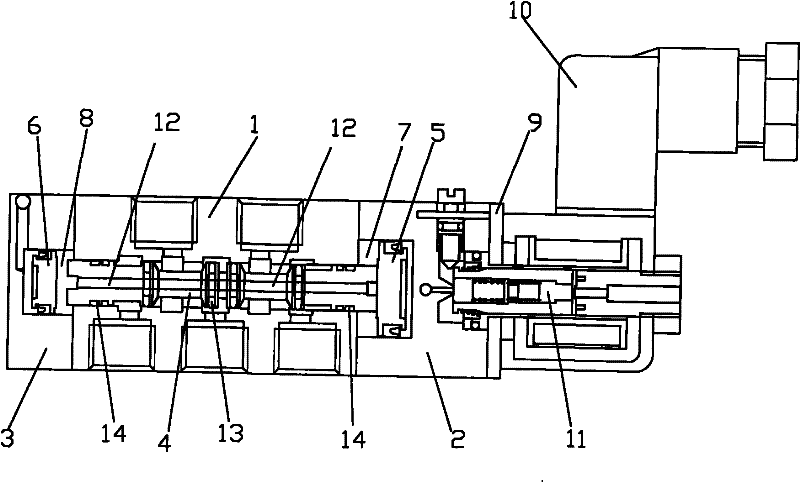

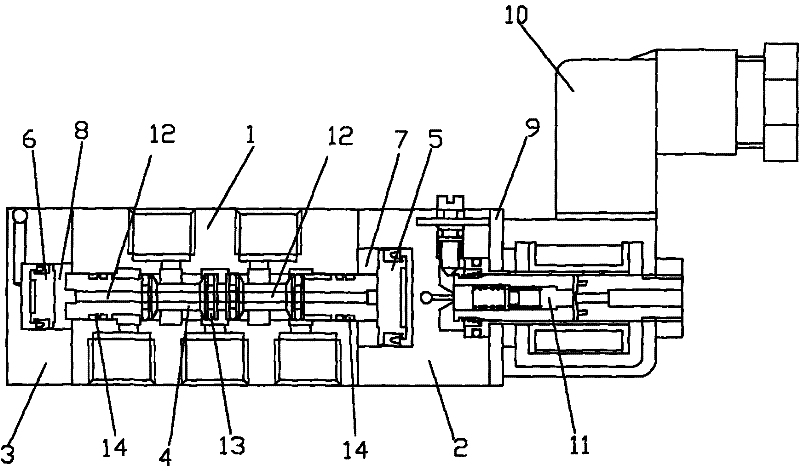

[0010] Refer to attached figure 1 and specific embodiments to illustrate the present invention.

[0011] An electronically controlled reversing valve, comprising a valve body 1, front and rear covers 2 and 3 at both ends of the valve body 1, a sliding valve stem 4 is arranged inside the valve body 1, and large and small pistons are respectively arranged at both ends of the sliding valve stem 4 5, 6, on the front and back covers 2, 3, there are large and small piston cavities 7, 8 corresponding to the large and small pistons, and a gland 9 and a coil assembly 10 are arranged in sequence at the end of the front cover 2, and the coil assembly 10 is provided with There is a sleeve assembly 11 for opening and closing the air circuit and moving the piston. The sliding valve rod 4 is provided with a hollow groove 12, and the two ends of the hollow groove 12 communicate with the large and small piston chambers 7 and 8 respectively. The valve ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com