Ten-in-one low-carbon circular ecological greenhouse model

A ten-in-one, carbon cycle technology, applied in the field of agriculture, can solve the problems of simplicity, single biological population, limited use of solar energy, etc., and achieve the effect of simple labor procedures and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

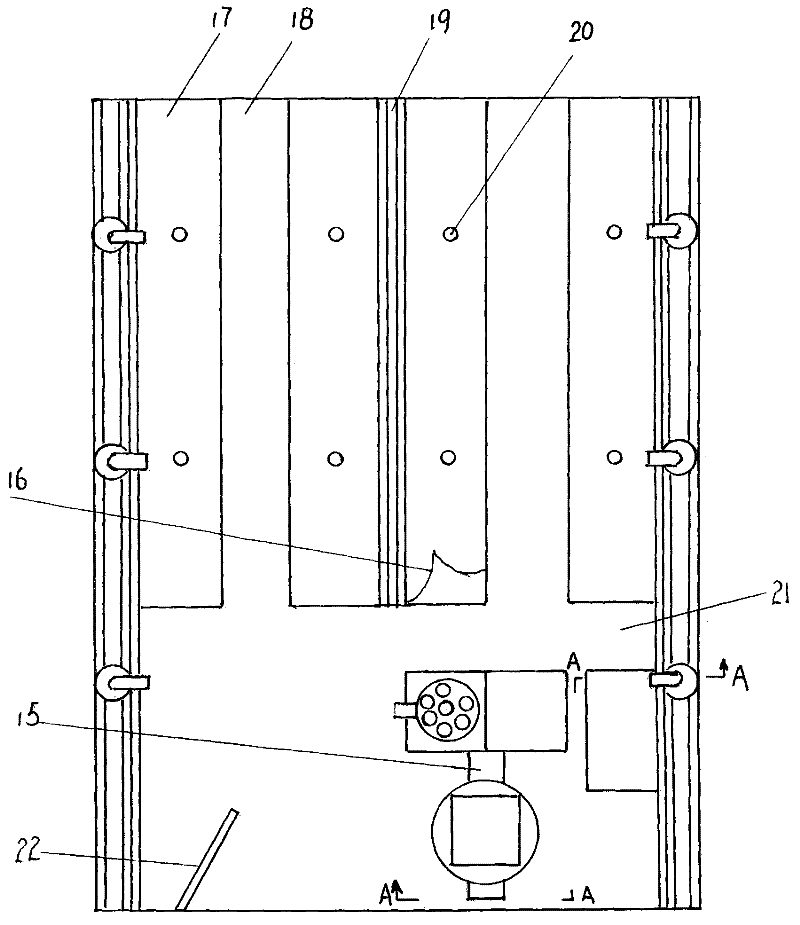

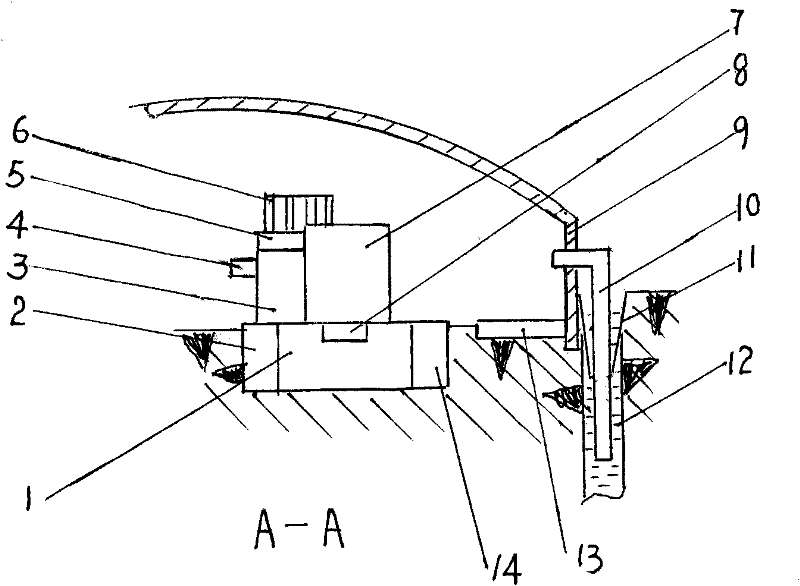

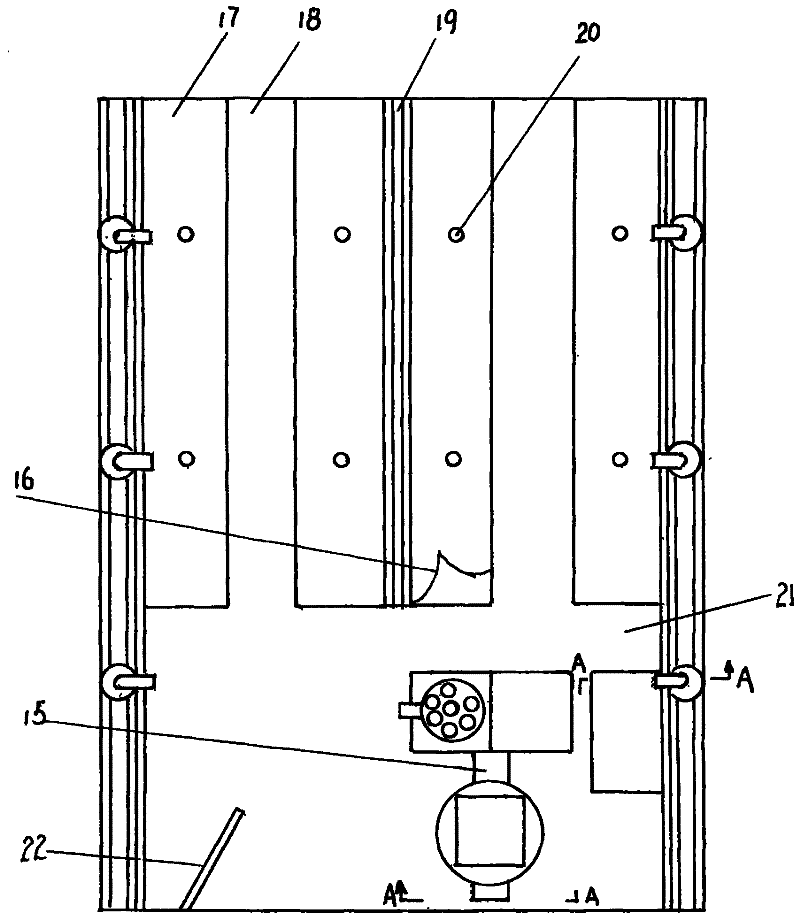

[0008] Below in conjunction with accompanying drawing, the present invention will be further described;

[0009] The ten-in-one low-carbon circular ecological greenhouse mode is composed of organic soilless cultivation tanks 17, animal biological beds 13, and biogas digesters 1. It is characterized in that several wells are evenly distributed in the two temperature-adjusting and high-yield ditch 11 12. On the well 12, there is a pipeline 10 leading to the steel frame greenhouse 9, and the opening and closing are controlled by a valve; a steel frame greenhouse 9 is arranged in the center of the two temperature-adjusting high-yield ditches 11, and the steel frame greenhouse 9 is surrounded by The mud dug out of the two temperature-adjusting and high-yield ditches 11 is used as a wall, and a fully enclosed black and white plastic film is arranged on the steel frame greenhouse 9 in winter, and a black sunshade net for sun protection is arranged in summer; the right side of the stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com