Method and device for actively suppressing pressure oscillations in a hydraulic system

A hydraulic system and pressure technology, applied in the field of actively suppressing pressure fluctuations and devices in hydraulic systems, to achieve the effect of suppressing pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

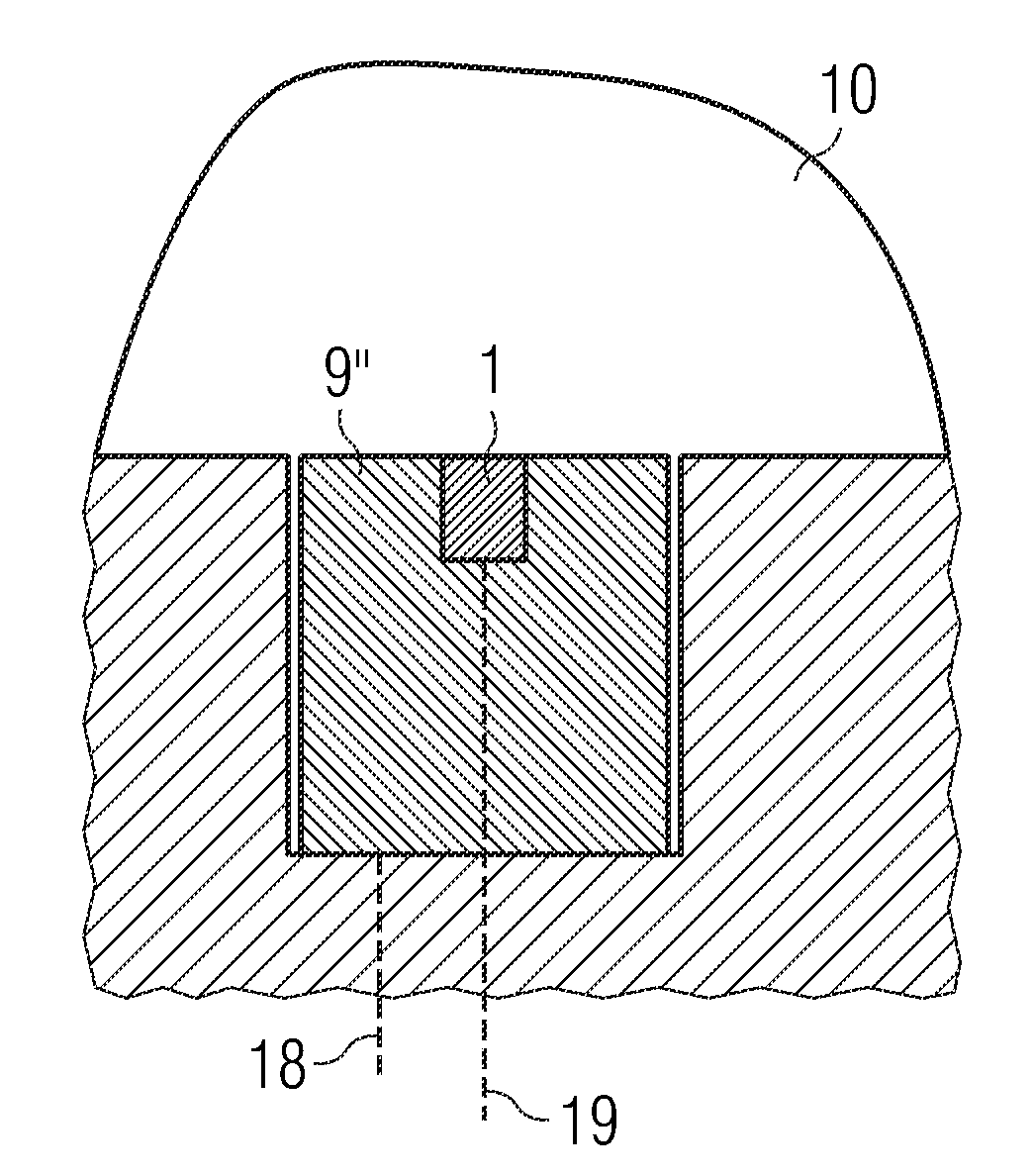

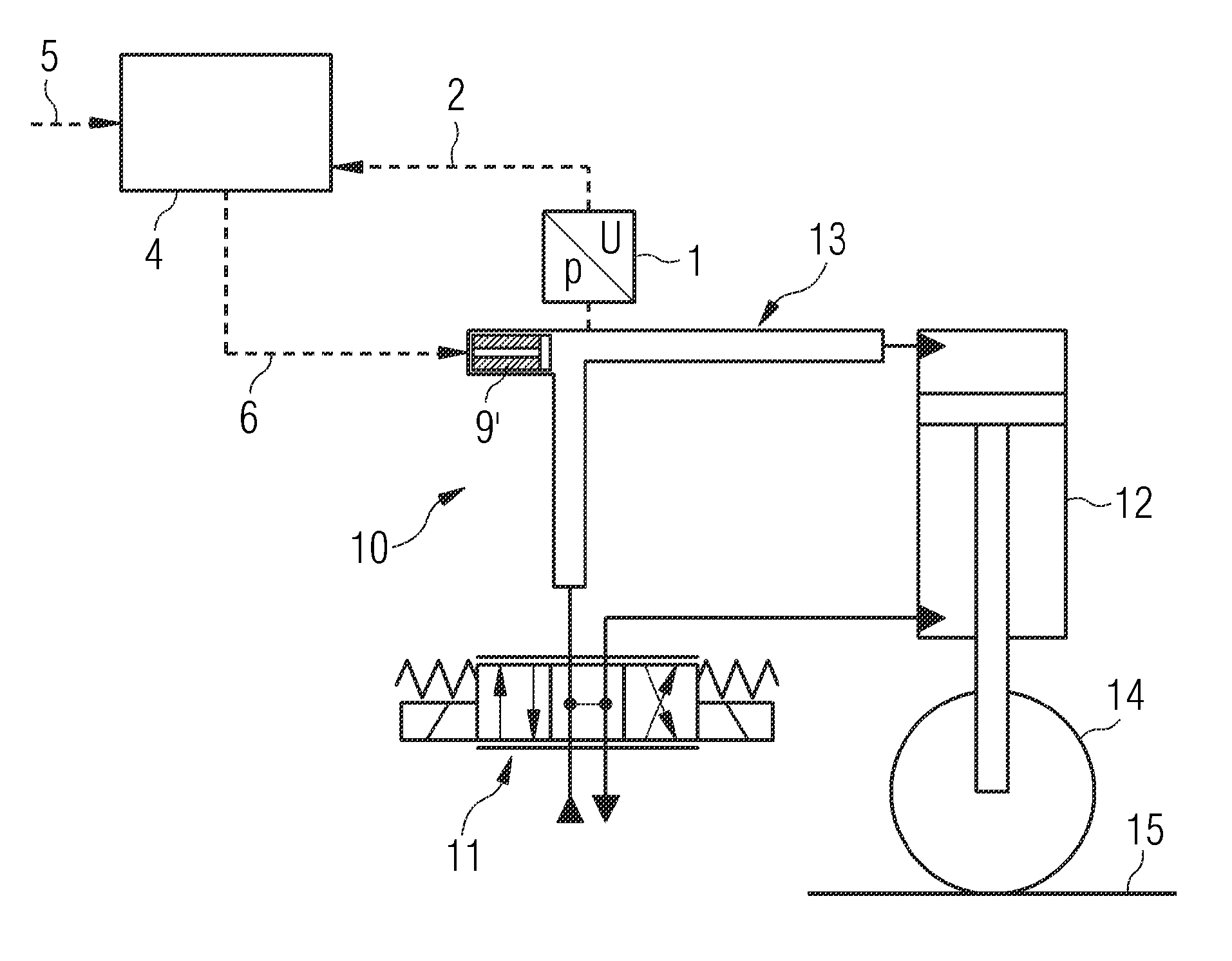

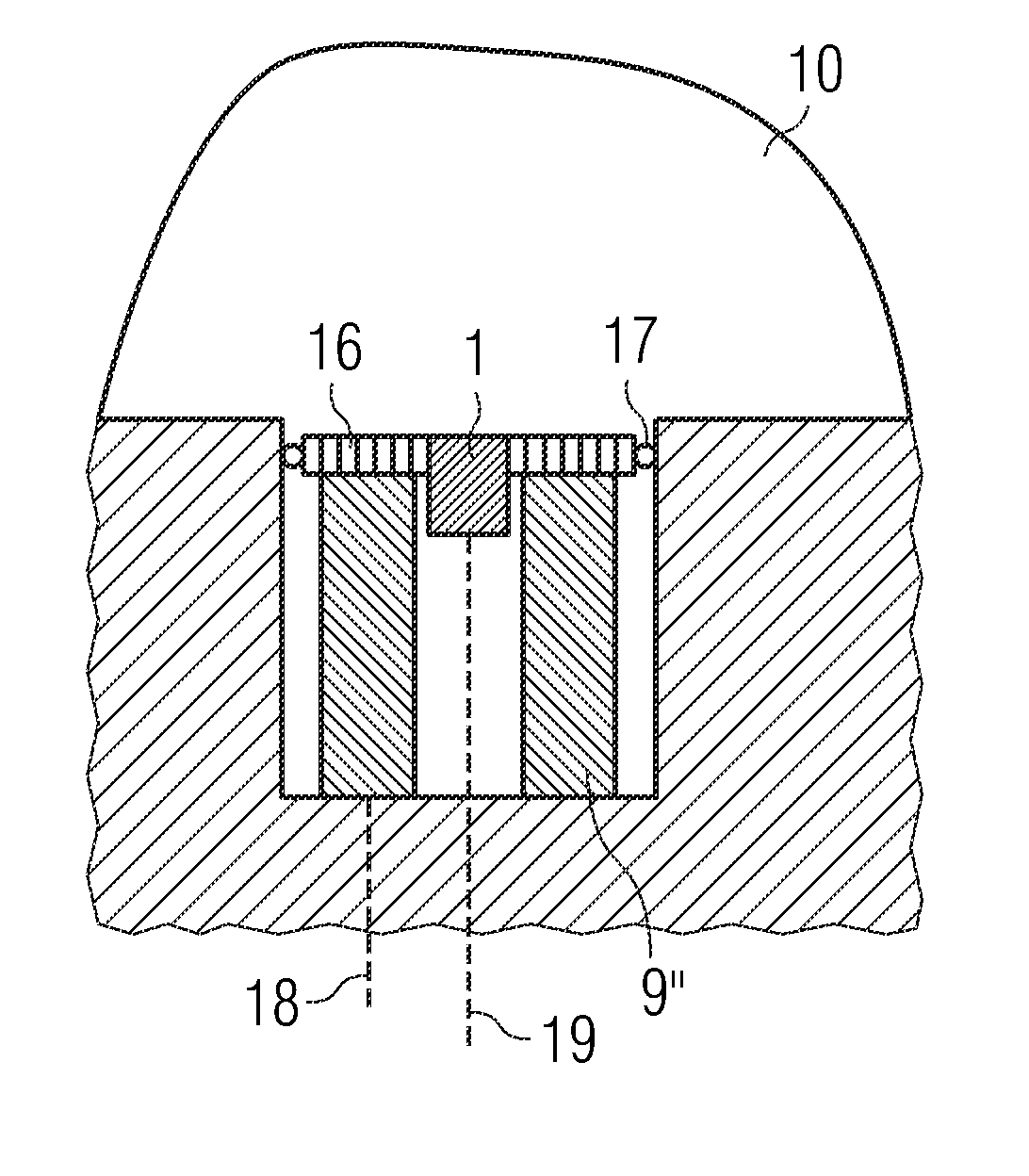

[0028] figure 1A basic configuration of a controlled object for suppressing pressure fluctuations in a hydraulic system of a rolling mill train is shown. The pressure signal 2 in the hydraulic system 10 is detected by the pressure detector 1, and the pressure signal 2 is delivered to the high-pass filter 3 (for details about the electronic circuit, for example, refer to Cambridge University Press P. Horowitz, The Art of W. Hill of Electronics 2nd Edition 1989, page 35), the high-pass filter 3 determines the alternating component of the pressure signal 2 ′ and supplies it to the controller 4 . This controller 4 calculates the time-varying control variable 6 in real time by means of the control law, taking into account the alternating component 2' and the nominal value 5, and sends this control variable 6 to the lead / lag element (Lead / Lag Glied ) 7. The phase shift of the control variable 6 is changed by the lead / lag element 7 , thereby at least partially compensating for a ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com