Flapping wing flight adopting compound flapping mode

A flapping-wing aircraft and driving mechanism technology, applied in the field of flapping-wing aircraft, can solve the problems of low reliability and large empty weight of the flapping-wing aircraft, and achieve the effects of small lift resistance and high aerodynamic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

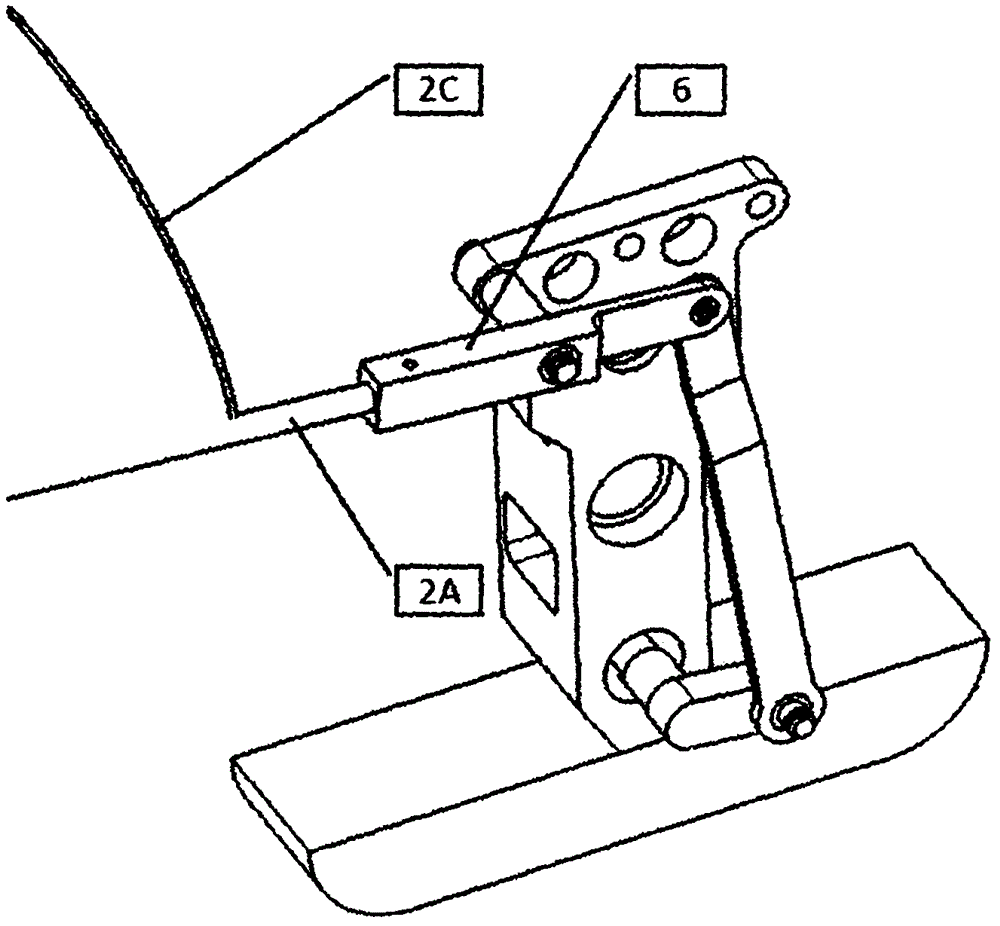

[0028]The composite flapping-wing aircraft of the present invention comprises a fuselage, a flapping wing and an empennage, and the fuselage is a composite material thin shell structure in the form of a cabin body, made of a glass fiber resin-based composite material or a carbon fiber resin-based composite material , left and right symmetrical, divided into nose 1A and body 1B.

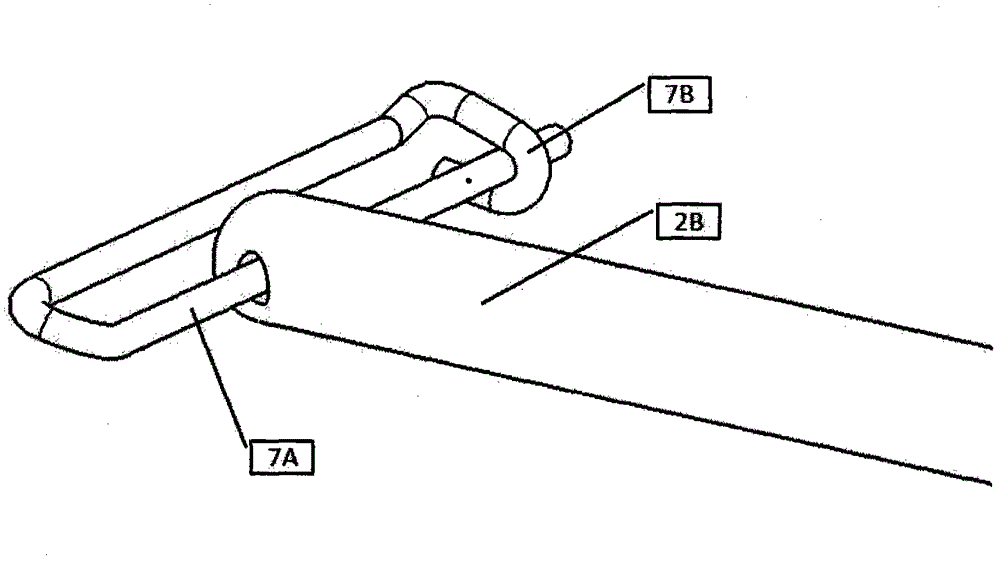

[0029] There is at least one supporting frame inside the body 1B for fixing the flapping wing drive mechanism. If the number of the supporting frame is more than one, except for the supporting frame that fixes the flapping wing drive mechanism, the remaining supporting frames play a supporting role in the body, and are arranged in the following locking device, steering gear installation position and empennage Positions where concentrated loads such as fixed positions act. The front part of the airframe 1B has a straight section with a rounded rectangle in cross section, where the flight control and n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com