Carbon-fiber-reinforced polyethylene composite material

A composite material and carbon fiber technology, which is applied in the field of composite materials to achieve the effects of good toughness, improved environmental stress resistance and good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

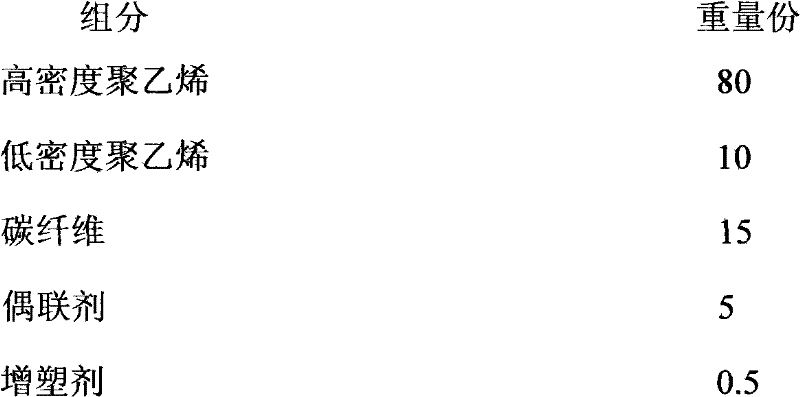

[0018] A carbon fiber reinforced polyethylene composite material, which consists of the following components (parts by weight):

[0019]

[0020] The preparation method is as follows: firstly, the ingredients are mixed according to the content of each component, and then high-density polyethylene, low-density polyethylene, maleic anhydride grafted polyethylene and carbon fiber are added to the double-roller plastic mixer, and the coupling is added during the mixing process. agents and plasticizers. The kneading temperature is 220° C., and the kneading time is 12 minutes; the kneaded material is molded to obtain a carbon fiber-reinforced polyethylene composite material.

Embodiment 2

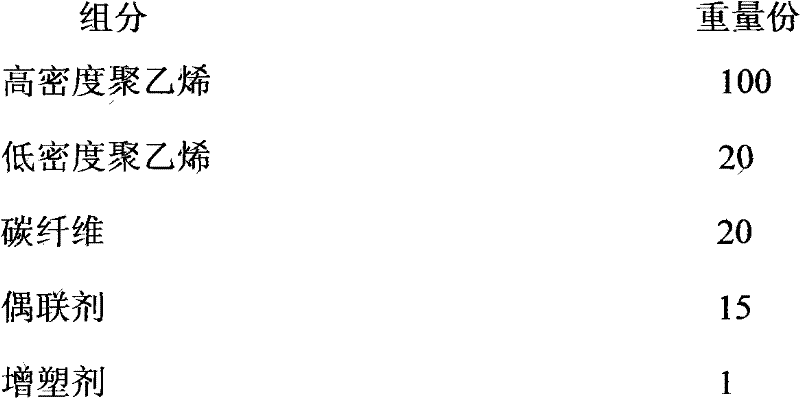

[0022] A carbon fiber reinforced polyethylene composite material, which consists of the following components (parts by weight):

[0023]

[0024] The preparation method is as follows: firstly, the ingredients are mixed according to the content of each component, and then high-density polyethylene, low-density polyethylene, maleic anhydride grafted polyethylene and carbon fiber are added to the double-roller plastic mixer, and the coupling is added during the mixing process. agents and plasticizers. The kneading temperature is 250° C., and the kneading time is 20 minutes; the kneaded material is molded to obtain a carbon fiber reinforced polyethylene composite material.

Embodiment 3

[0026] A carbon fiber reinforced polyethylene composite material, which consists of the following components (parts by weight):

[0027]

[0028] The preparation method is as follows: firstly, the ingredients are mixed according to the content of each component, and then high-density polyethylene, low-density polyethylene, maleic anhydride grafted polyethylene and carbon fiber are added to the double-roller plastic mixer, and the coupling is added during the mixing process. agents and plasticizers. The kneading temperature is 230° C., and the kneading time is 15 minutes; the kneaded material is molded to obtain a carbon fiber-reinforced polyethylene composite material.

[0029] The carbon fibers in the above three embodiments are all modified in advance: reflux the carbon fibers with a 1:1 acetone-ethanol solution for 15 hours, remove the epoxy resin on the surface of the carbon fibers, dry at 80°C to remove the solvent, and then impregnate maleic anhydride The monomer is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com