Automatic detection mechanism for appearance integrity of ball bed high-temperature reactor fuel element

A fuel element and automatic detection technology is applied in the field of automatic detection mechanism for the appearance integrity of fuel elements of pebble bed high temperature reactors, to achieve the effect of avoiding missed detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

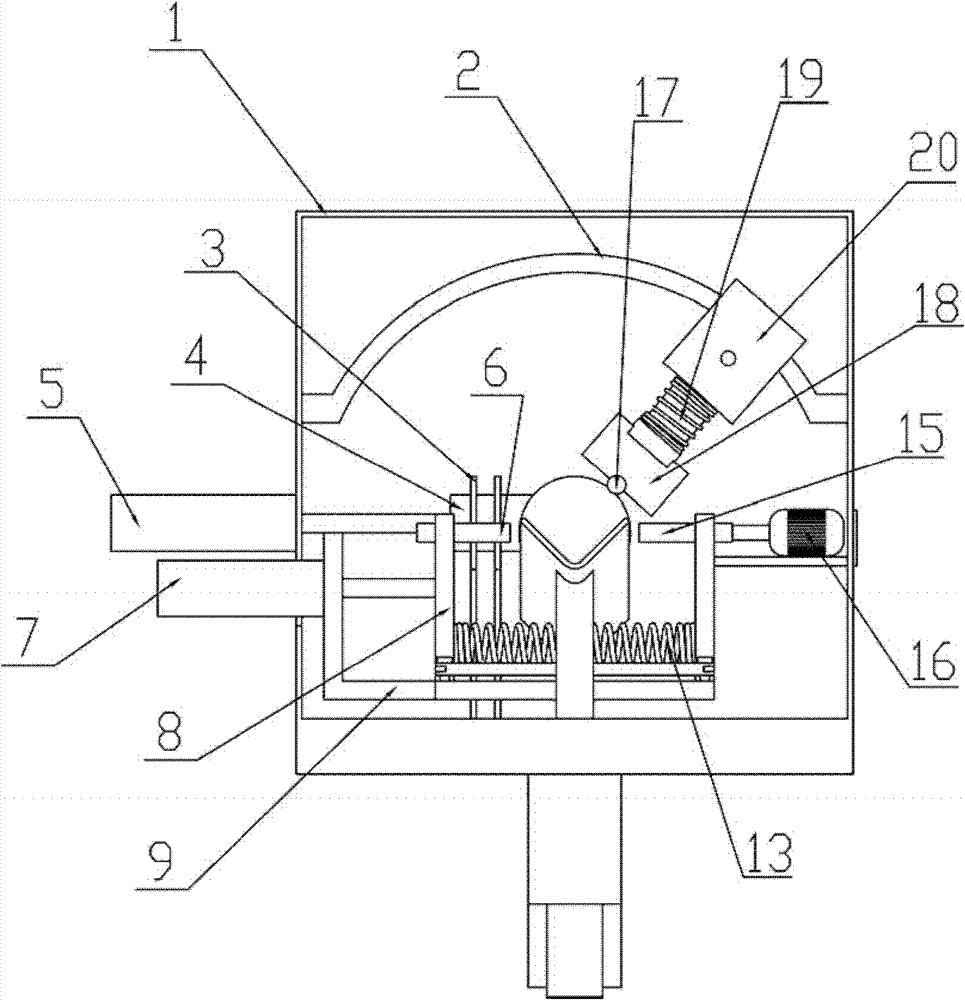

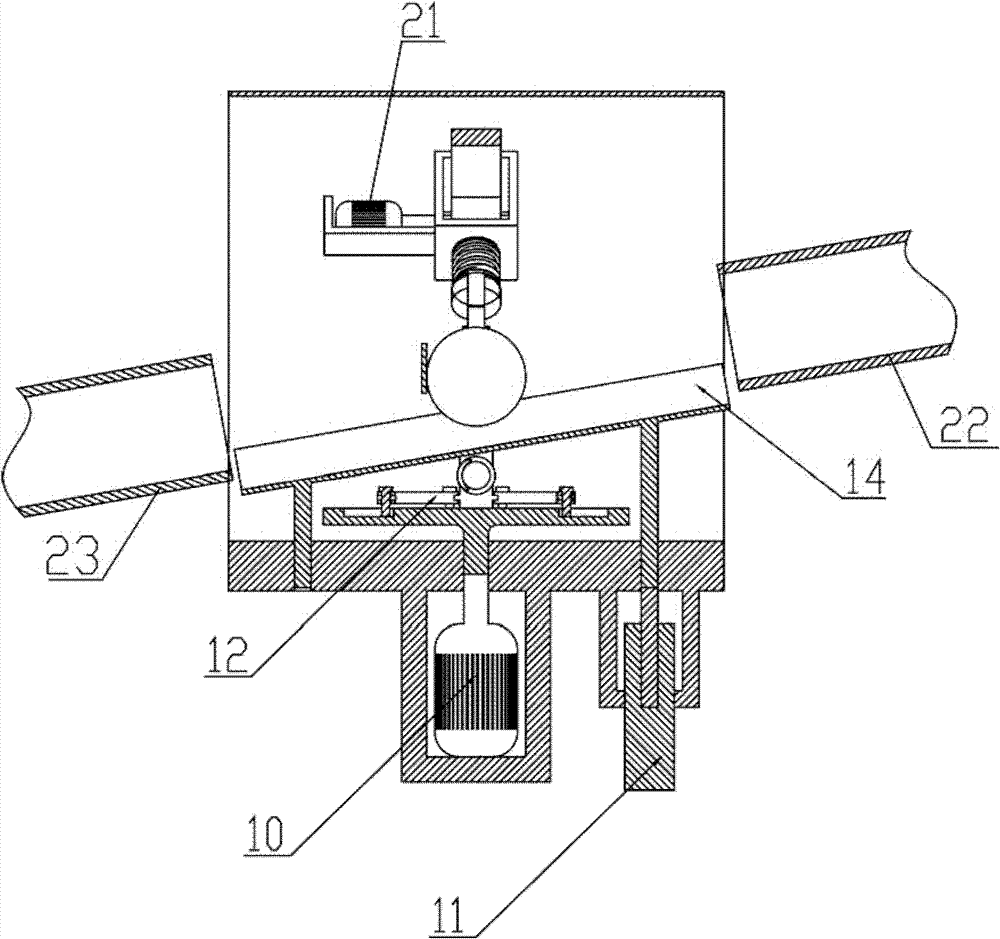

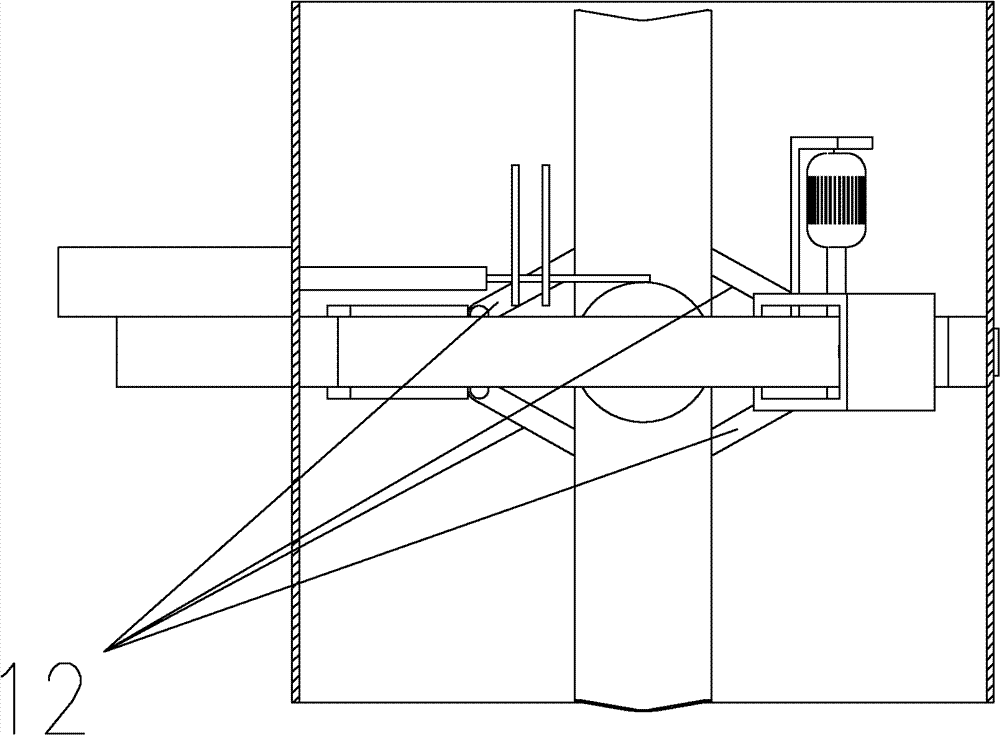

[0028] Such as Figure 1~3 As shown, it is a schematic diagram of an automatic inspection mechanism for the appearance integrity of a pebble bed high temperature reactor fuel element provided by an embodiment of the present invention. The detection mechanism includes a frame 1, a detection assembly, a clamp assembly, a clamp rotation assembly and a component guide rail assembly. The components mainly include: 1: rack; 2: arc rack guide rail; 3: component baffle slideway; 4: component baffle; 5: baffle driver; 6: passive rotating component clamp; 7: component clamp Bracket driver; 8: Component clamp bracket; 9: Rotating bracket; 10: Rotating bracket motor; 11: Component guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com