Method for monitoring coal bed gas parameter in real time

A real-time monitoring, coal seam gas technology, applied in surveying, earthwork drilling, wellbore/well components, etc., to achieve the effect of easy on-site operation, wide practicability, and accurate data monitoring results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

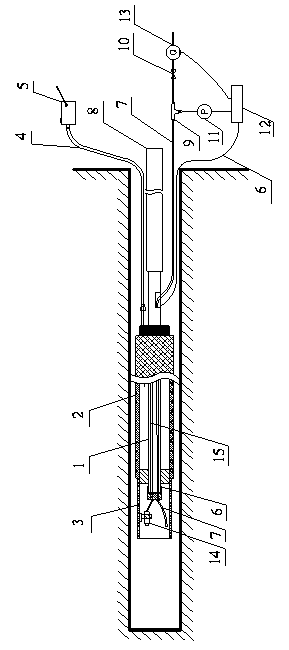

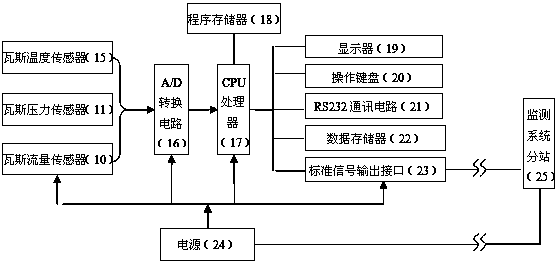

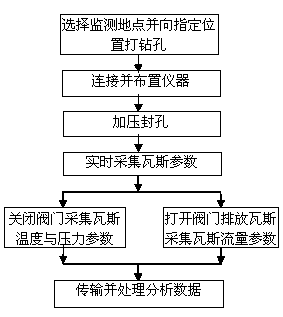

[0023] Such as figure 1 , figure 2 As shown, the coal seam gas parameter real-time monitoring device of the present invention is mainly composed of a hole sealer, a gas parameter sensor, a data acquisition instrument 12 connected to the gas parameter sensor, and a booster pump 5; wherein: the hole sealer is mainly composed of a supporting steel pipe 1, The sealing capsule 2, the front cover 3, the pressurizing pipe 4, the sealing joint 6, the gas pipe 7 and the push rod 8 are composed; the sealing capsule 2 is fixed on the supporting steel pipe 1, and the front end of the sealing capsule 2 is connected with the front cover 3 , the outer wall of the front cover 3 is a filter screen with air permeability, which can prevent coal dust from polluting the sensor; the push rod 8 is connected to the supporting steel pipe 1, the sealing capsule 2 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com