Measurement method of plane mirror included angle in multiplane-mirror catadioptric system

A catadioptric and multi-plane technology, which is applied in the field of angle measurement of plane mirrors, can solve problems such as difficulty in measuring angles between plane mirrors, and achieve the effect of improving accuracy, system stability and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to better understand the technical solution of the present invention, further detailed description will be given below in conjunction with the accompanying drawings.

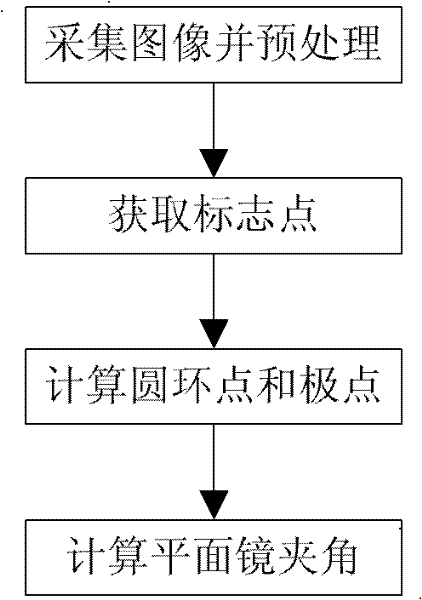

[0030] Depend on figure 1 From the system flow chart, it can be seen that the entire processing process of the system consists of four stages: data preprocessing, acquisition of identification points, calculation of ring points and poles, and final acquisition of mirror angles.

[0031] 1. Data preprocessing

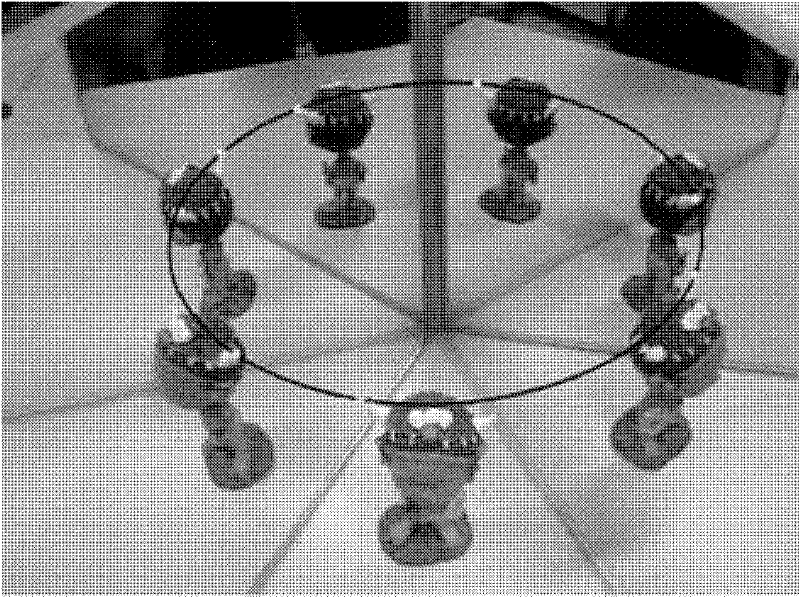

[0032] This phase includes the acquisition of image data— figure 2 For the data samples, the calibration of the internal and external parameters of the monocular camera, and the background modeling to ensure the real-time performance of the system.

[0033] Since the hardware acquisition system of the present invention is composed of a monocular camera and a multi-plane mirror, it is not necessary to consider the problem of synchronous control and acquisition of images involved in the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com