Low concentration photovoltaic generating module

A technology of concentrating photovoltaics and power generation modules, applied in the field of solar photovoltaics, can solve the problems of reducing the use effect and life of the system, reducing the cost of the original intention, and unfavorable for the normal operation of the cells, so as to avoid daily tracking and macular effect , reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

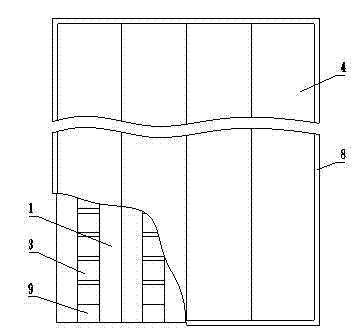

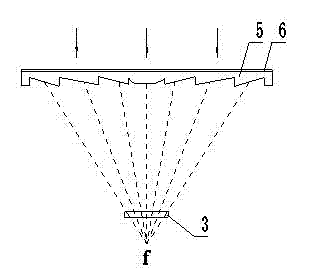

[0024] Referring to the accompanying drawings, the present invention coats the outer surface of the glass or transparent resin substrate 5 of the component module with an optical film 6 to make a coated transparent cover plate 4, and the optical film 6 is a composite optical film.

[0025] The glass or transparent resin substrate 5 has a thickness of 2.8 to 5 mm. Silicon dioxide (SiO2), titanium dioxide (TiO2), zirconium dioxide (ZrO2), aluminum oxide (Al2O3), and Niobium (Nb2O5), tantalum pentoxide (Ta2O5), and magnesium fluoride (MgF) are used as raw materials, and are plated into single-layer, double-layer, three-layer or multi-layer composite optical dielectric films.

[0026] Appropriate matching and thickness design of these film materials can make the coated transparent cover plate 4 have an anti-reflection effect on the relevant bands of the solar spectrum (0.4-1.1 μm), and different film system designs can obtain different anti-reflection effects; It can block ultrav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com