Transportation device

A technology for conveying devices and conveying media, which is applied in printing devices, transportation and packaging, thin material processing, etc., and can solve problems such as uneven crimping force, uneven spring 150 installation errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

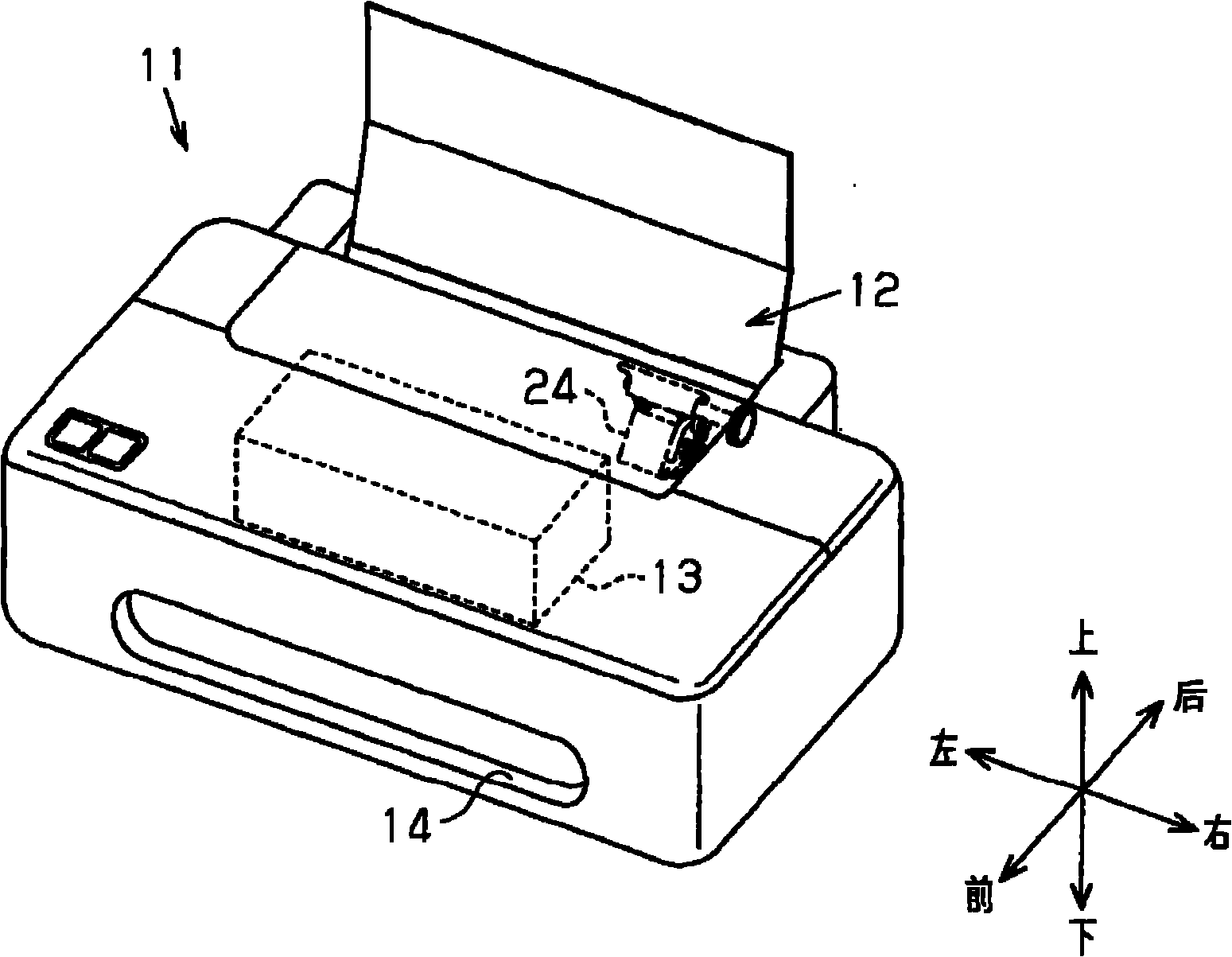

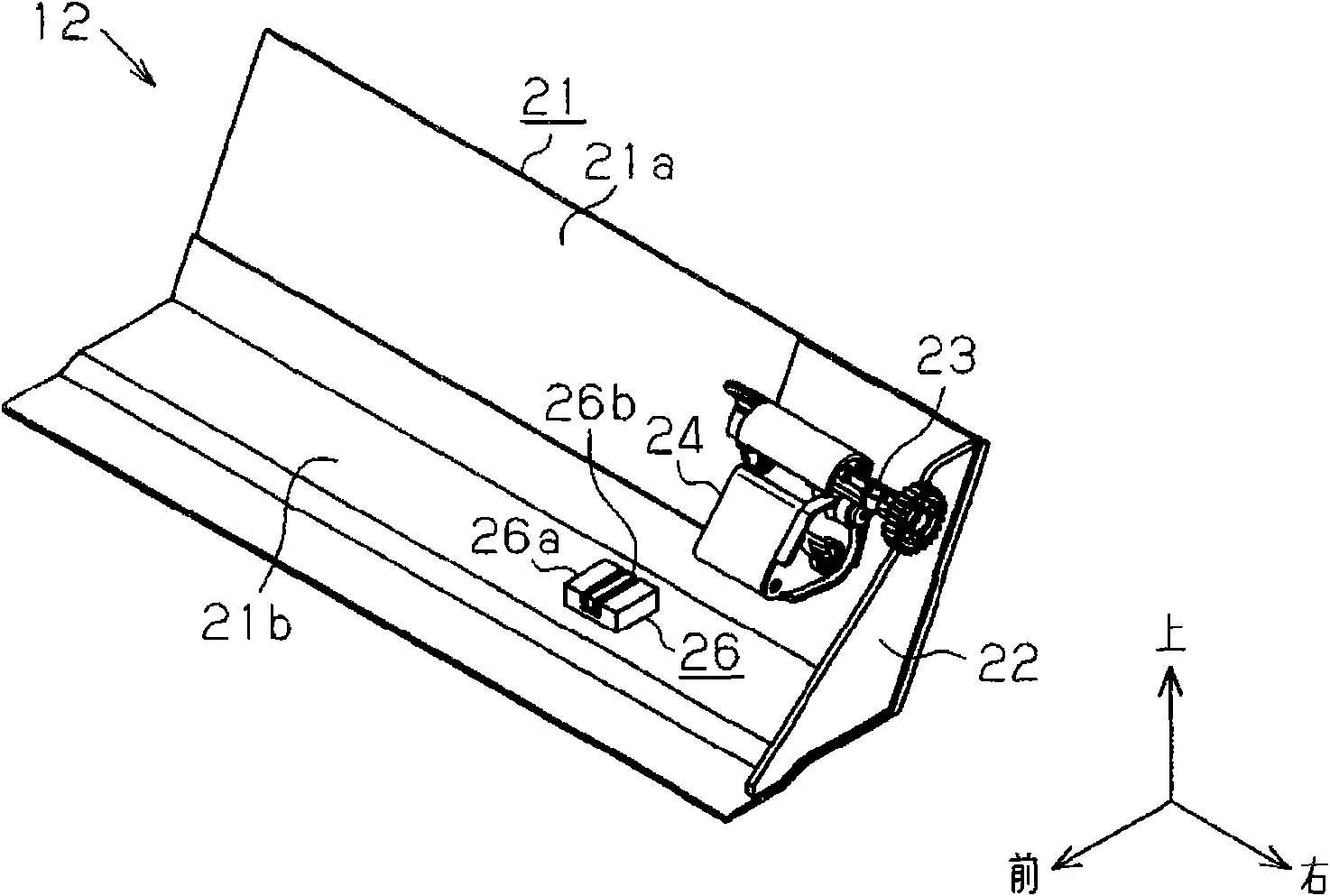

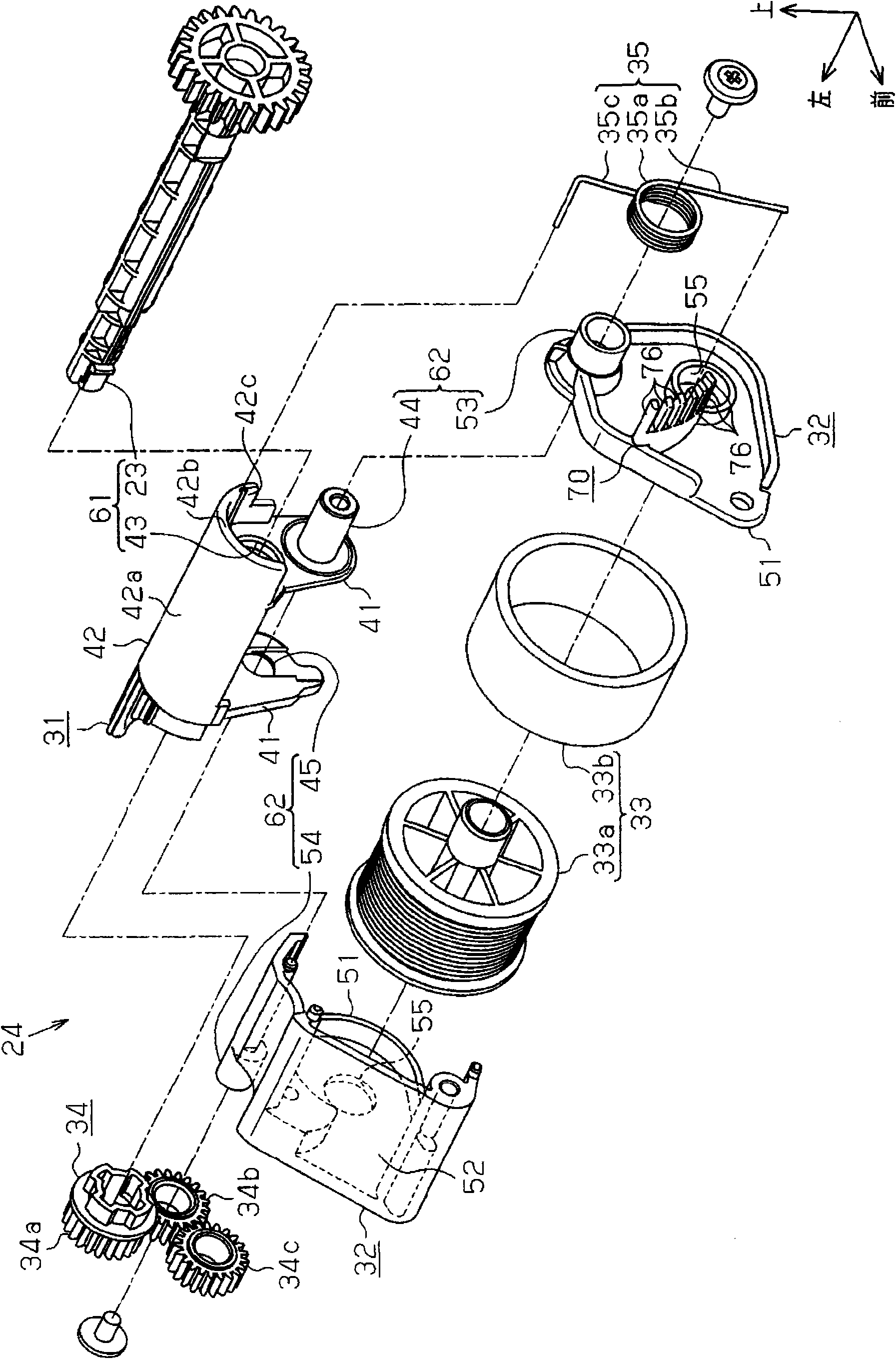

[0033] Below, refer to Figure 1 to Figure 9 , the specific embodiment of the conveying device used as an inkjet printer (hereinafter referred to as "printer") will be described. In addition, in the following description, unless otherwise specified, the use of "front-rear direction", "up-down direction" and "left-right direction" means figure 1 The "front-back direction", "up-down direction" and "left-right direction" indicated by the middle arrows. In addition, in this embodiment, the vertical direction is defined as the same direction as the vertical direction.

[0034] Such as figure 1 As shown, the printer 11 is a recording device that records characters, images, and the like on paper as a conveyed medium supplied from the rear side. The printer 11 includes: a conveying device 12 that is an Auto Sheet Feeder (ASF: Auto Sheet Feeder) for conveying paper; a recording device 13 that records an image or the like on the paper conveyed by the conveying device 12; The paper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com