Trimmer for tea garden

A technology for trimming machine and tea garden, applied in the field of agricultural and forestry machinery, can solve the problems of high labor intensity, difficulty in meeting the requirements of ridge trimming of tea trees, and inability to prune both sides of shrubs at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

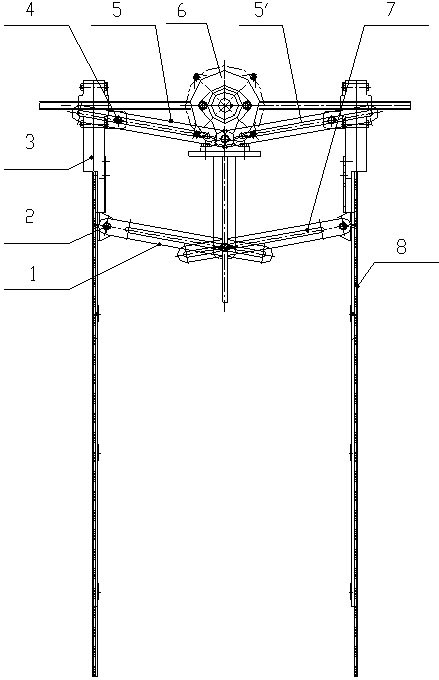

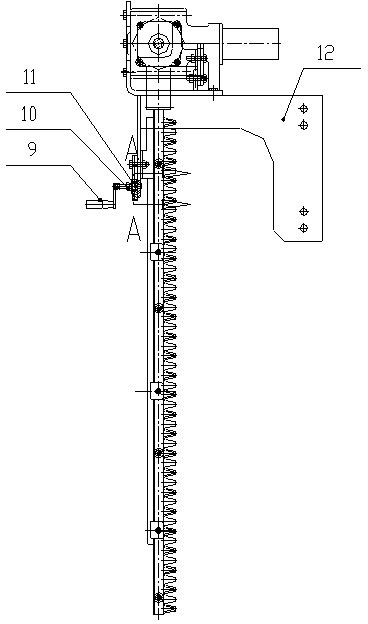

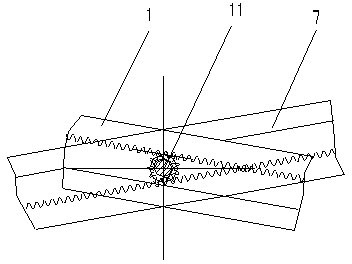

[0018] The tea garden trimming machine of present embodiment is as figure 1 and figure 2 Shown, have power assembly 6 and cutter assembly 3,8. For the structure of the cutter assembly, see Figure 5 , Image 6 , the left and right casings 3-2, 3-4 are combined to form an eccentric wheel composed of two eccentric bearings 3-10 with angular positions staggered, and the two eccentric wheels are respectively connected to each other through the connecting rod 3-9. Two staggered razor-shaped left and right blades 3-7, 3-6 are connected by transmission, and the two blades form a moving pair with the tool magazine extending from the housing, thus essentially forming a crank that converts rotation into reciprocating linear motion slider mechanism. The upper ends of the two sets of left and right blade assemblies 3, 8 are respectively hinged with one end of the left and right widening adjustment rods 5, 5' through bolts 4, and the middle part is respectively hinged with one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com