Multi-goal path planning of welding robots with automatic sequencing

A welding robot and path planning technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as unconsidered and uncontrollable robot paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

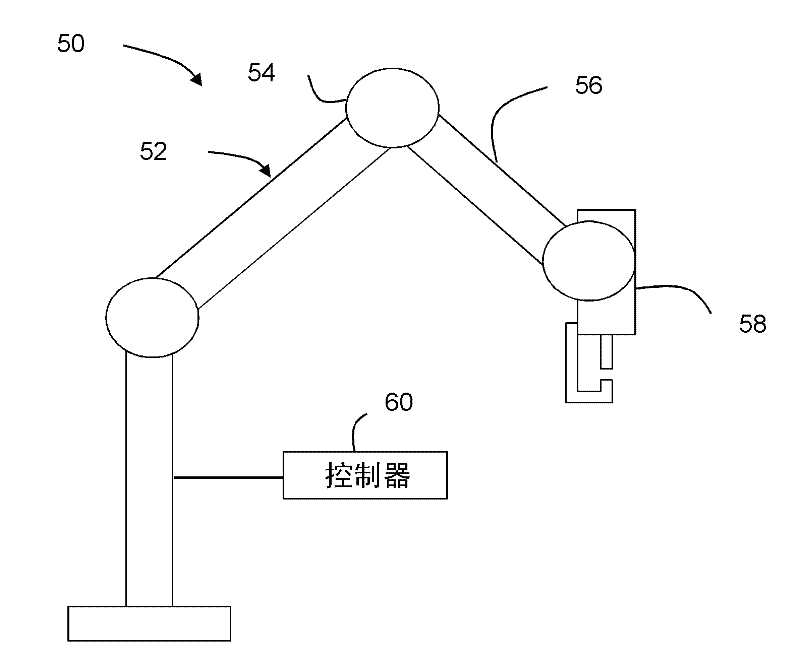

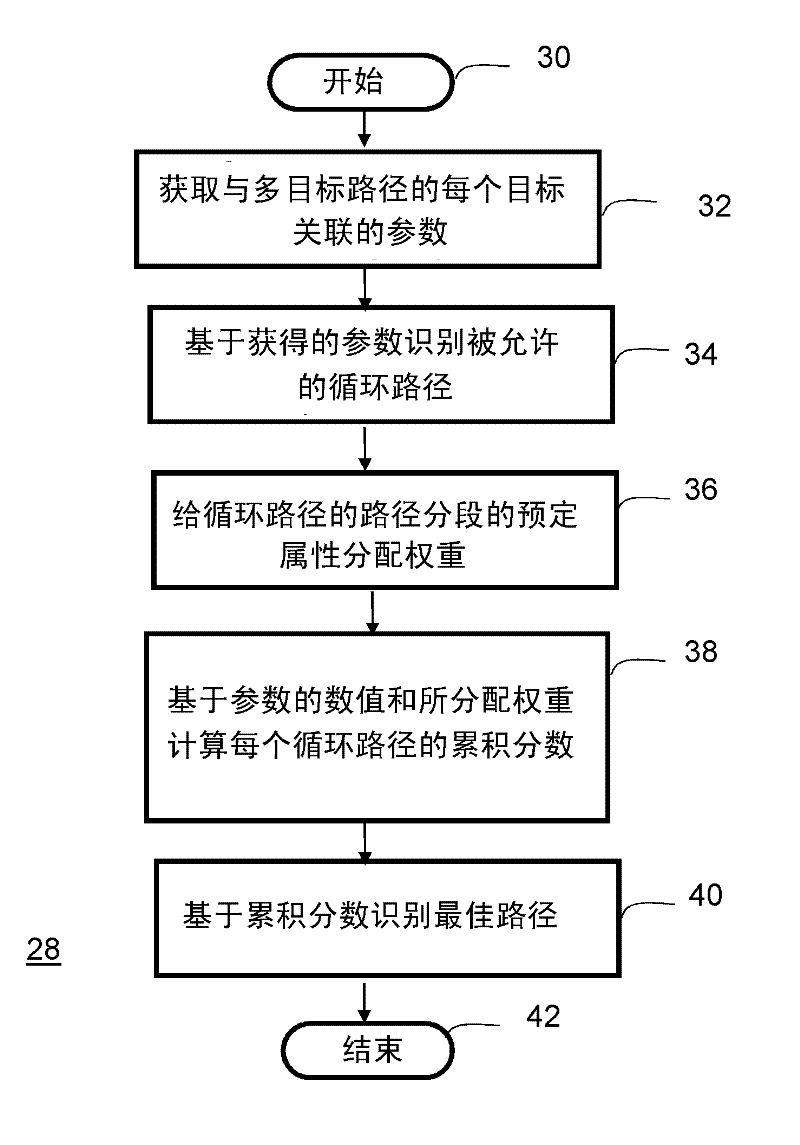

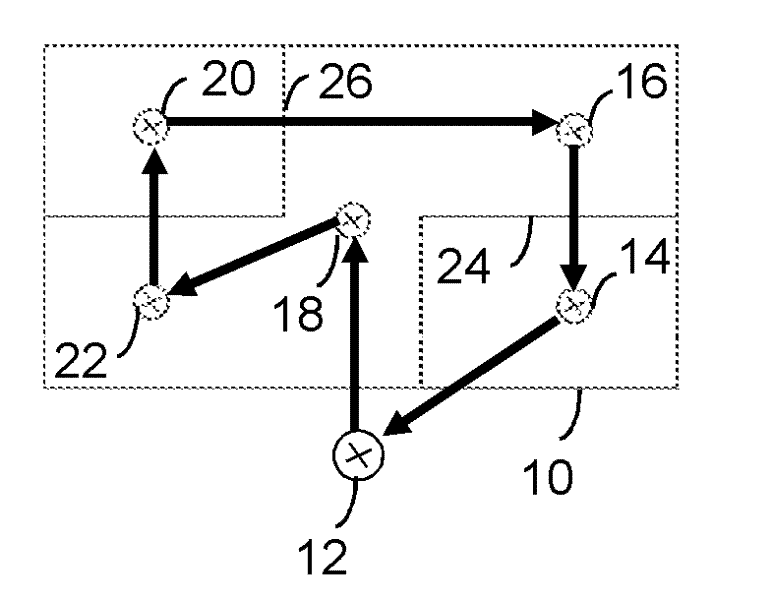

[0012] The following discussion of embodiments of the invention relating to systems and methods for providing multi-objective path planning for welding robots is merely exemplary in nature and in no way serves to limit the invention, its application or uses.

[0013] The present invention proposes a multi-objective optimal path planning algorithm for welding robots that takes the same geometric inputs - such as target structures, i.e. welding points and welding torch orientation at welding points, geometry of parts and fixtures, etc., The algorithm also generates collision-free paths that automatically determine the optimal welding sequence based on a specific cost function associated with the entire path. The cost may include one or more of cycle time, smoothness criteria of the path, and overall joint motion of the robot. The algorithm will run over all possible configurations independently generated by inverse dynamics and will thus be free from anomalies. The algorithm wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com