Water pump for vehicle

A water pump, vehicle technology, applied in engine cooling, climate sustainability, road transportation, etc., can solve problems such as increase in size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

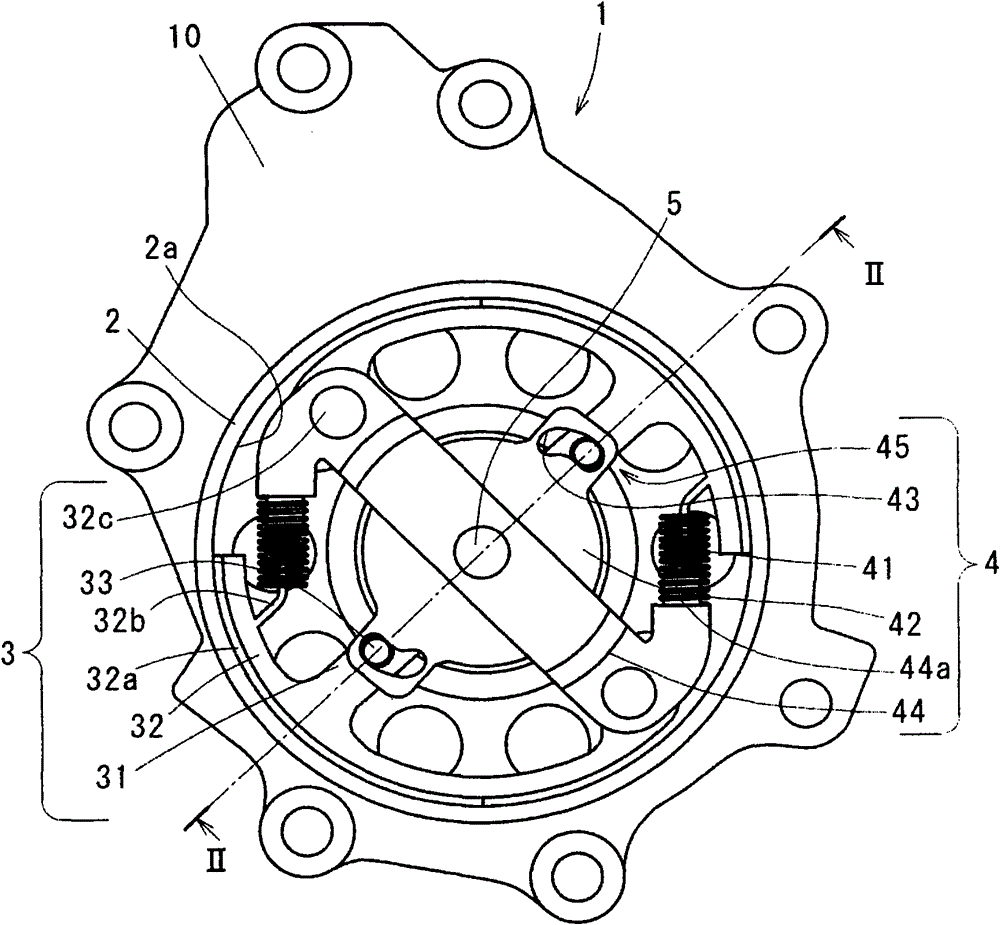

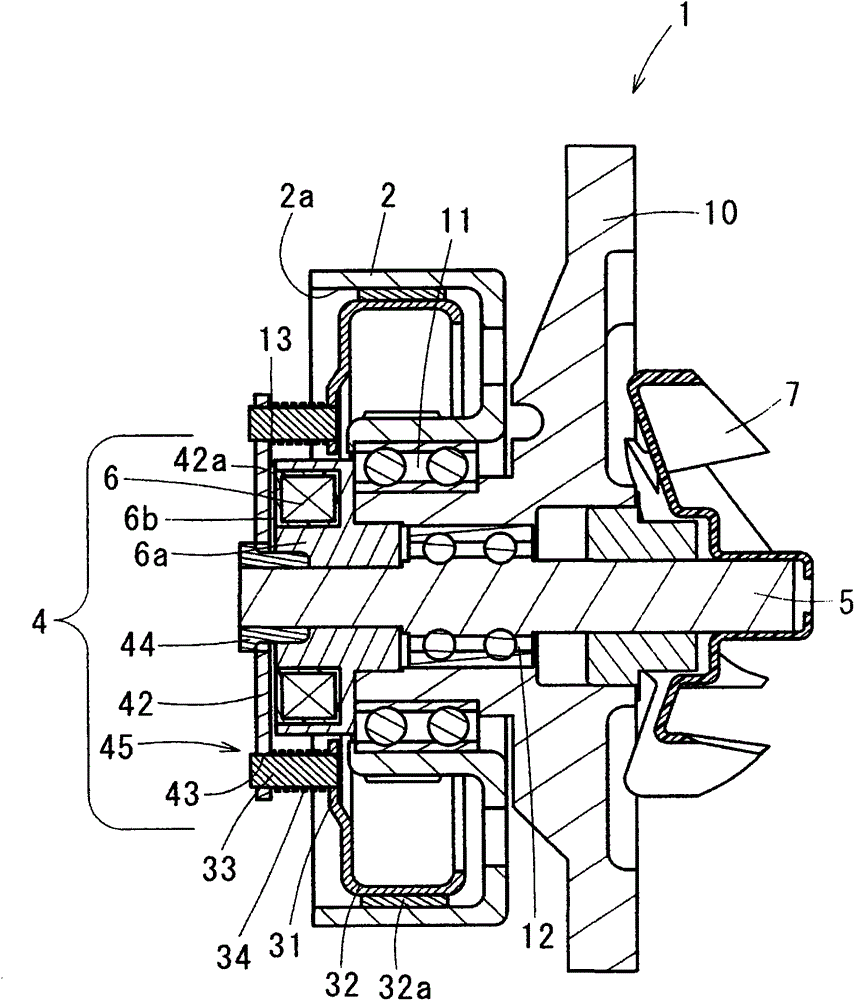

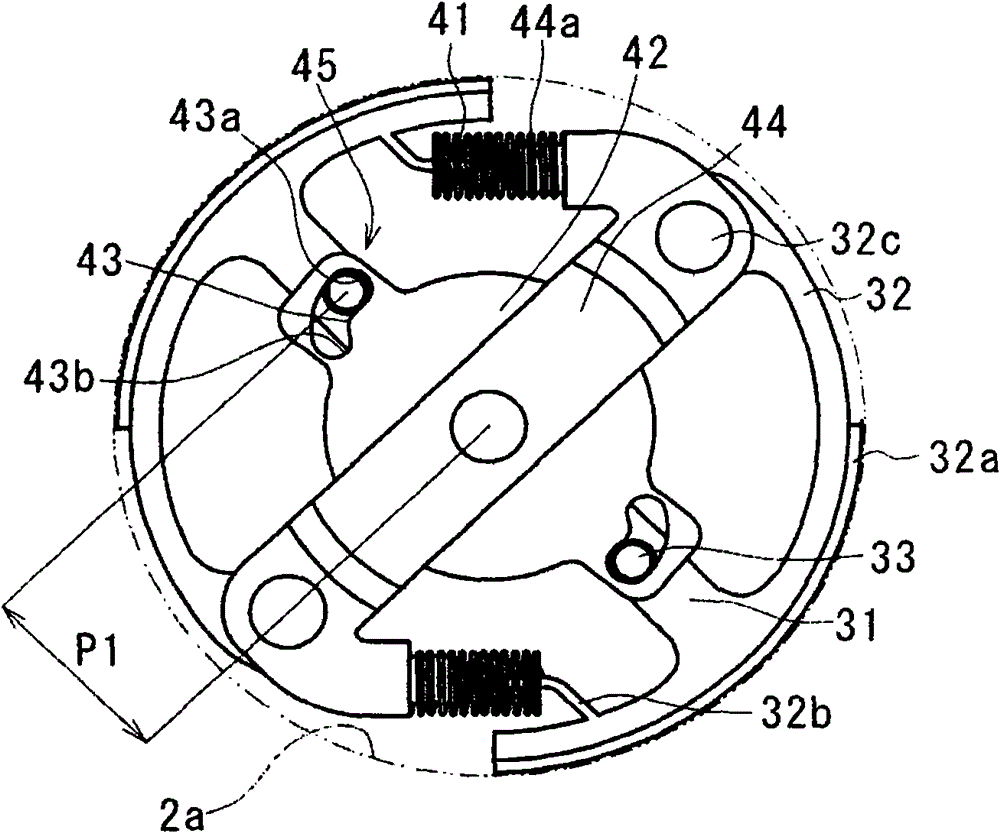

[0034] Below, refer to figure 1 Turning to FIG. 3, a first embodiment of the present invention is described.

[0035] like figure 1As shown, the vehicle water pump 1 (hereinafter referred to as the water pump) according to the first embodiment includes: a pump body 10, which has a water inlet and a water outlet; the friction portion 32a (as a pressing portion), which is positioned to face and press the inner peripheral surface 2a of the pulley 2; Rotation of wheel 2. The cooling water is pumped out to the part of the vehicle that needs cooling water, such as the internal combustion engine, through the water outlet, and returns to the water pump 1 through the water inlet. The water pump 1 also includes a control 4 . The control member 4 controls the arm member 3 so that the arm member 3 and the pulley 2 come into or out of contact with each other, and make the contact state (half-engagement state) between the arm member 3 and the pulley 2 variable. The water pump 1 further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com