Automatic loading device of lathe applicable to disc-type parts

A technology for automatic feeding and plate parts, applied in metal processing and other directions, can solve the problems of inability to realize automatic feeding, low work efficiency, and high labor intensity of operators, and achieve simple structure, reduce labor intensity, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

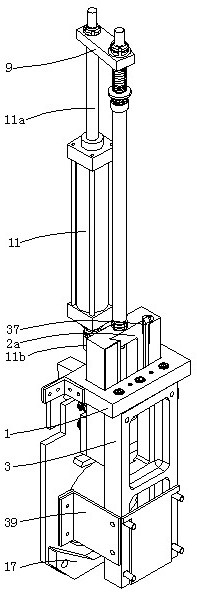

[0022] like Figure 1~5 As shown, the feeding device consists of a rectangular frame 1, a sliding plate 2, a fixed plate 3, a limit block 4, a limit screw 5, a push-pull rod 6, a spring 7, a limit washer 8, a connecting plate 9, and a lock nut 10 , double-piston cylinder 11, feeding actuator, feeding raceway 20, cylinder 21, connecting block 22, connecting piece 23, toggle piece 24, lever 25, pin shaft 26, "n" type lug 27, feeding Control pin 28, feeding control rod 29, solid connecting sheet 30, telescopic rod 31, feed raceway 32, upper pressing plate 33, pin 34, extension spring 35 and upper pressing plate limit block 36 etc. components are formed, wherein the rectangular frame 1 The sliding plate 2 is perforated in the square inner hole of the sliding plate 2, and a dovetail groove 2a is vertically opened on the left plate surface of the sliding plate 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com