Inkjet recorder

An inkjet recording and inkjet technology, which is applied in the direction of inking devices, printing devices, power transmission devices, etc., to achieve the effects of reducing space, preventing pollution, and preventing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

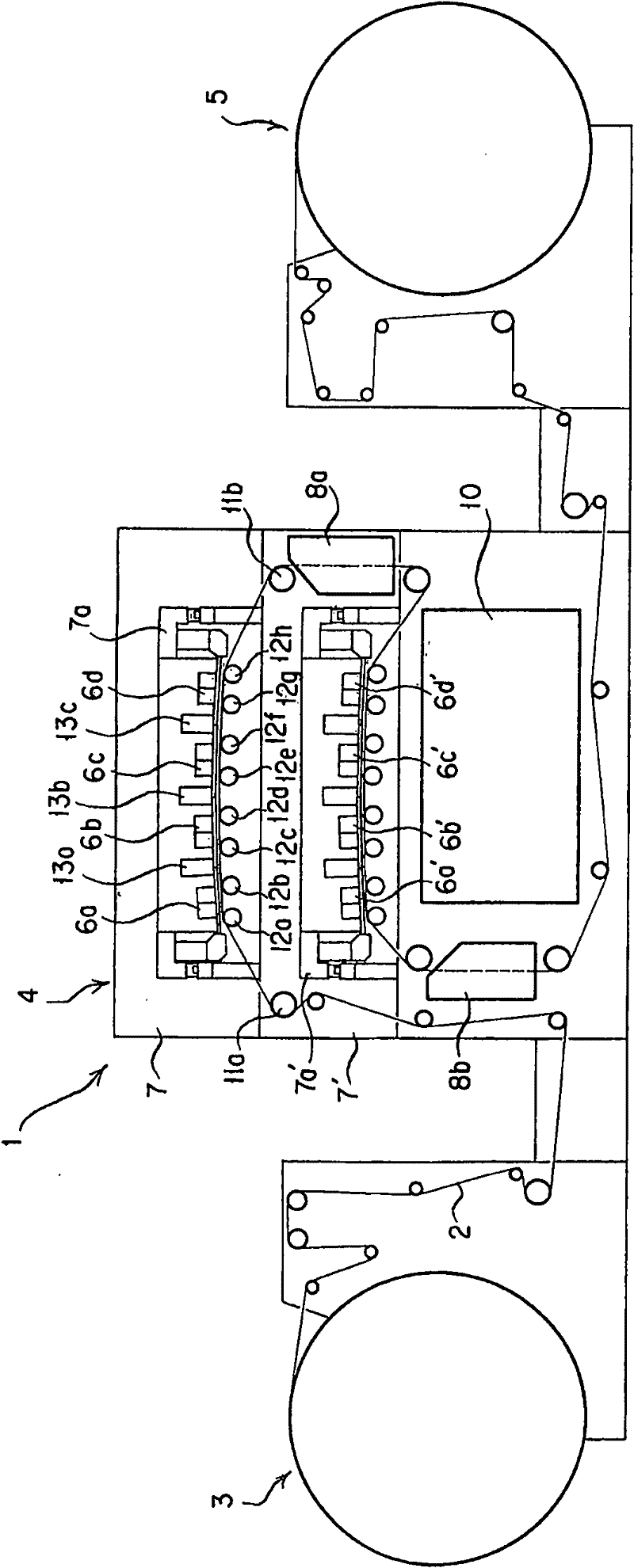

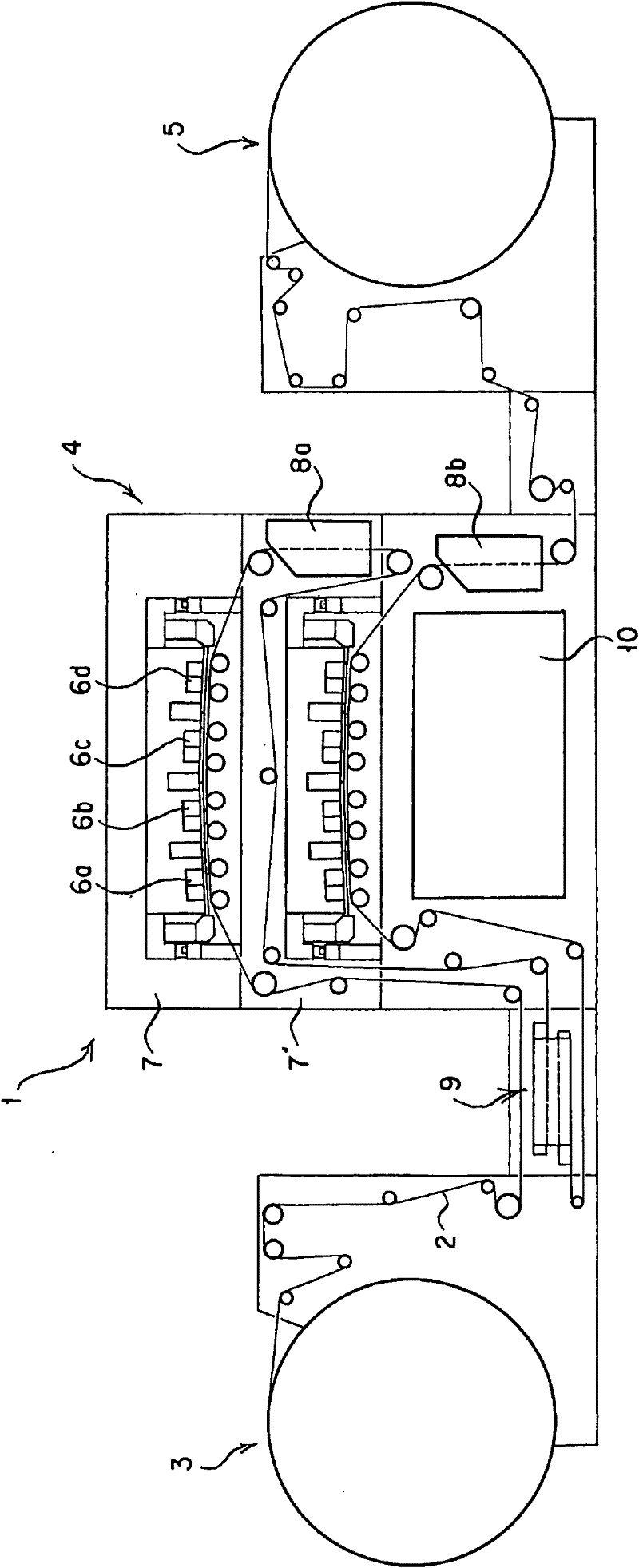

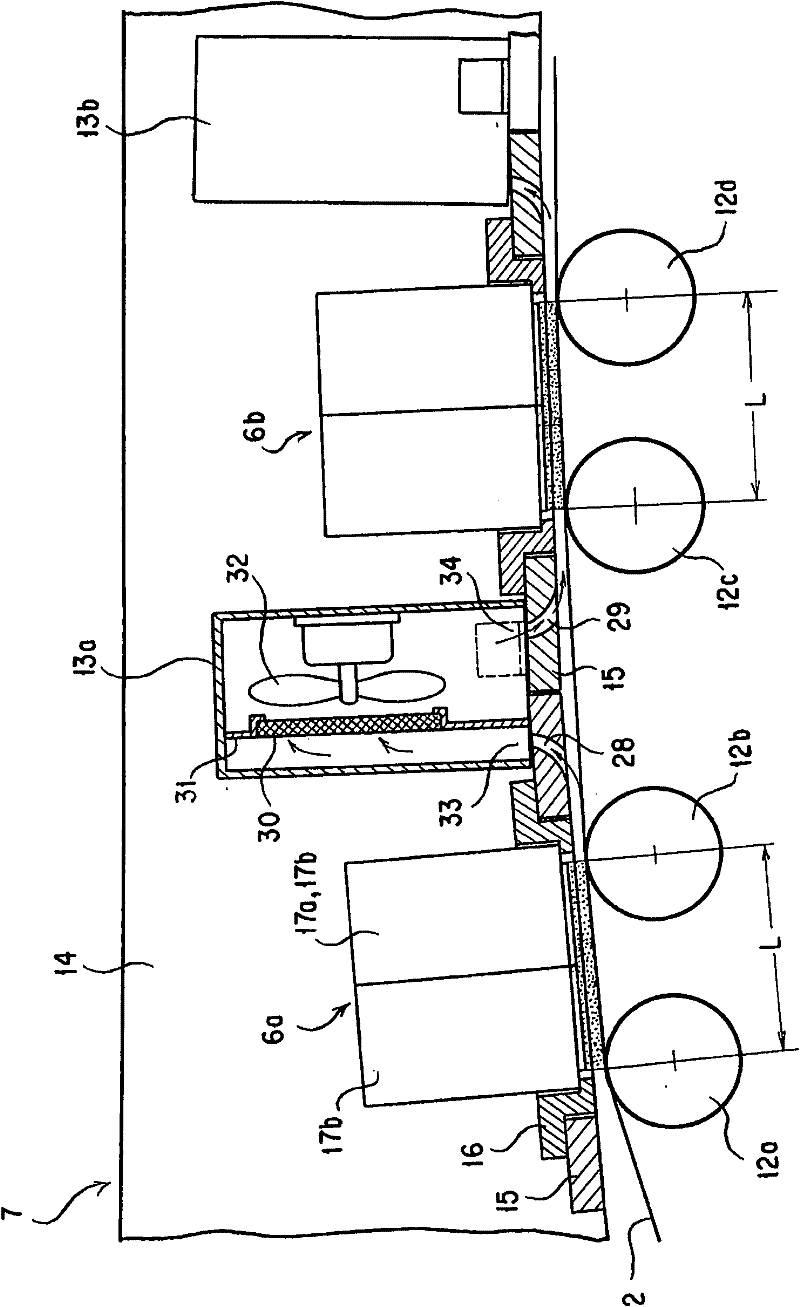

[0029] figure 1 The inkjet recording apparatus 1 according to the first embodiment of the present invention is schematically shown, and the inkjet recording apparatus 1 prints on the paper 2 supplied from the paper supply section 3 by the inkjet head. The inkjet printing unit 4 and the take-up unit 5 for winding the paper 2 printed by the inkjet printing unit 4 are constituted.

[0030] As the above-mentioned inkjet printing unit 4, it has a structure in which first and second printing units 7, 7' are superimposed on each other in the vertical direction. A plurality of, for example, four (Y, M, C, K) inkjet heads 6a, 6b, 6c, 6d and 6a', 6b', 6c', 6d' are arranged.

[0031] Moreover, in the first embodiment of the present invention, when the paper feeding direction of the paper 2 fed from the paper feeding unit 3 is referred to as the “forward direction” and the opposite direction is referred to as the “reverse direction”, the direction from the paper feeding unit 3 is The su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com