Method for adjusting a web changing roll device and a web changing roll device

A roll paper and paper roll technology, applied in the field of roll paper changer devices, can solve the problems of wrong, disadvantageous, inaccurate known printing material roll thickness or inertia, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

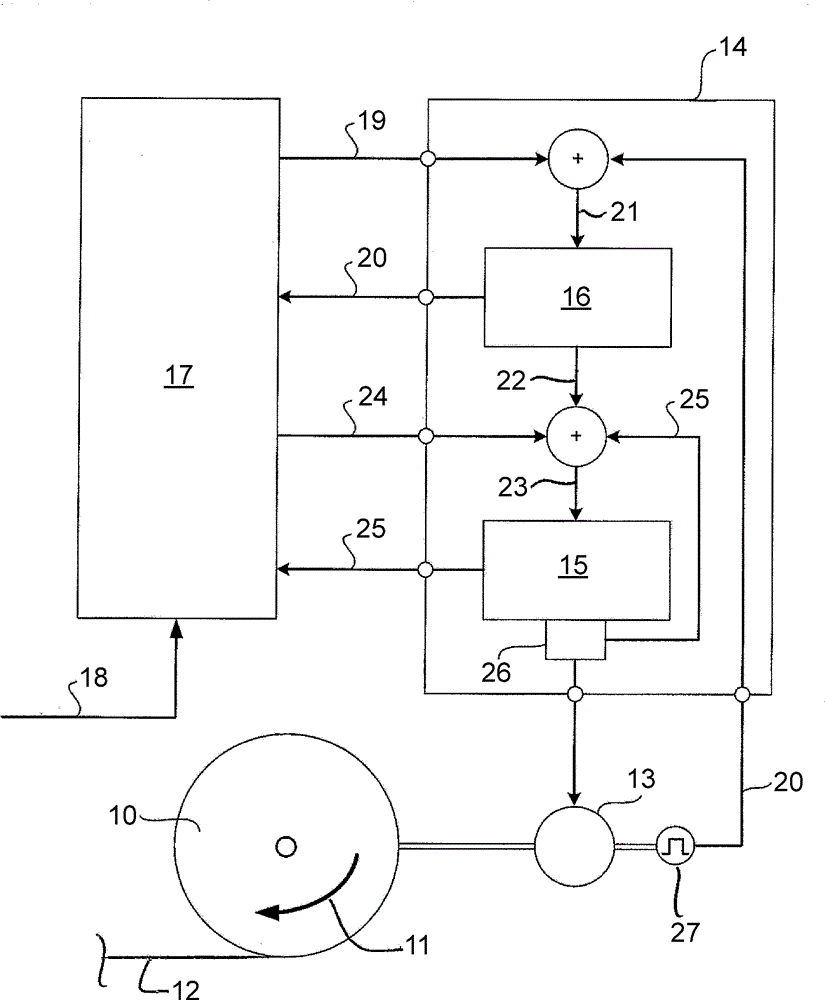

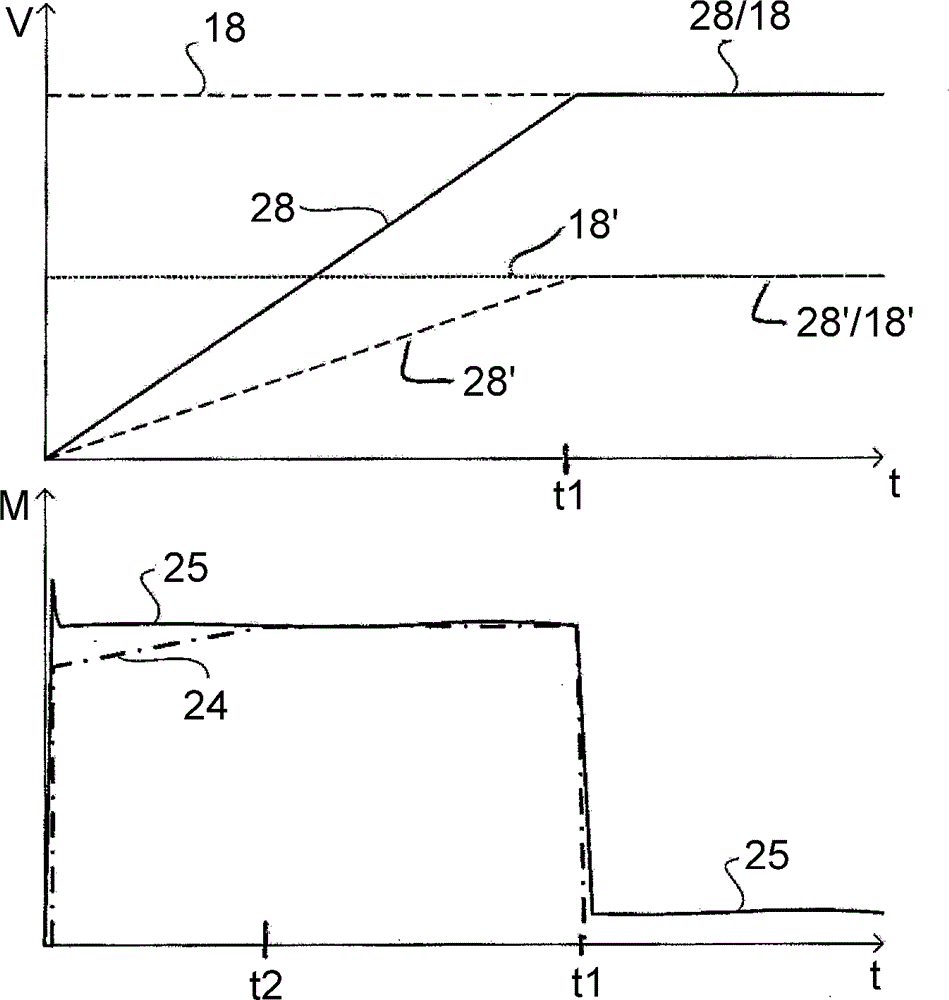

[0017] figure 1 A block diagram showing an adjustment structure of a web changing roll device for a web rotary printing machine according to the present invention, wherein according to figure 1 A printing material web 12 is unwound from a printing material roll 10 whose direction of rotation is indicated by arrow 11 . The printing material roll 10 is driven by an electric motor 13 , wherein the electric motor 13 is actuated via a cascaded control circuit 14 consisting of a current regulator 15 and a speed regulator 16 superimposed on the current regulator 15 . The cascade control loop 14 is used to regulate the rotational speed of the motor 13 driving the printing material roll 10 and thus the rotational speed or peripheral speed of the printing material roll 10 or the web speed of the printing material web to be unwound from the printing material roll 10 . In the illustrated preferred embodiment, the control computer 17 and the cascade control circuit 14 cooperate. The spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com