Longitudinal axial flow threshing device with side window

A longitudinal axial flow, threshing device technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of difficult observation of technical status and working conditions, no observation, cleaning of debris, inconvenient use and maintenance by users, etc. Easy to clear, easy to close, easy to open effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

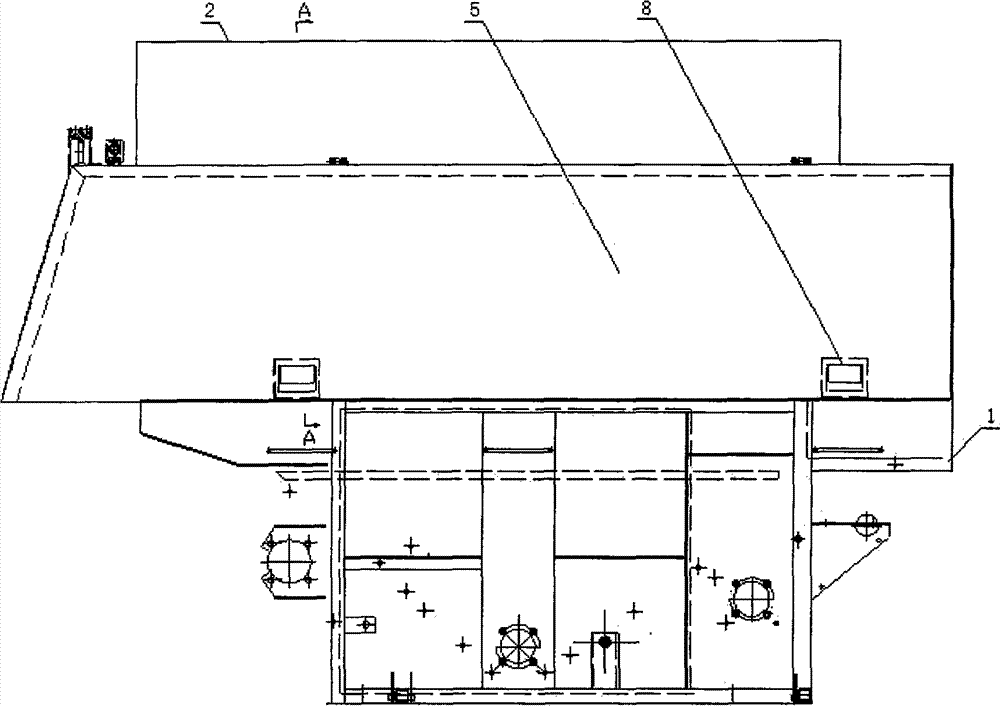

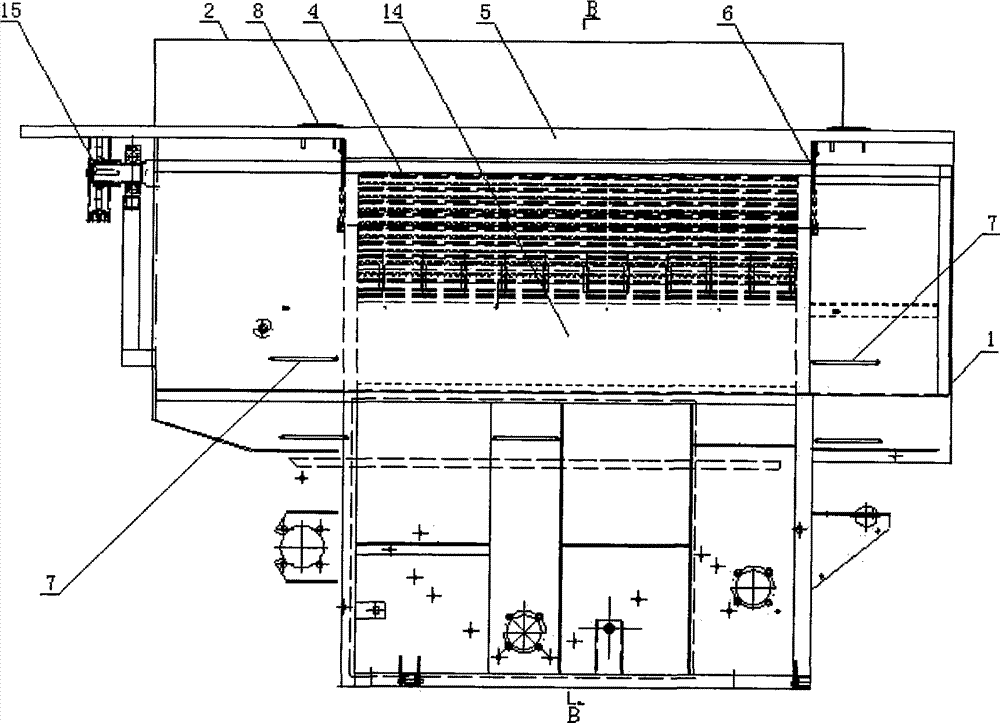

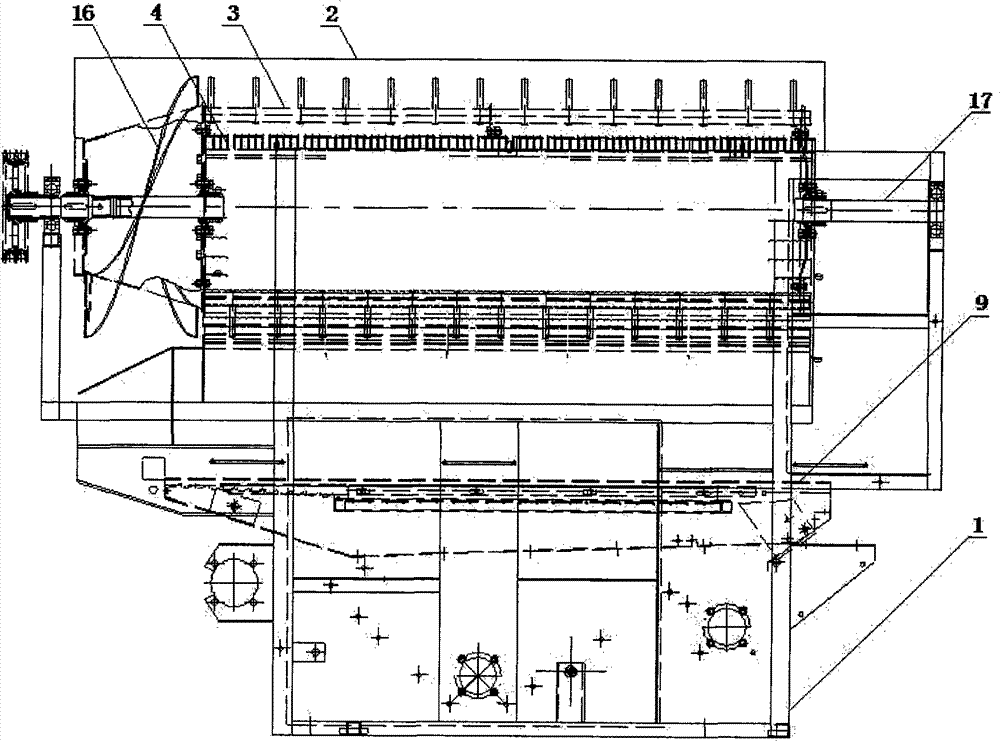

[0022] Examples, see attached Figure 1~6 A longitudinal axial flow threshing device with side windows, including a frame 1, a threshing assembly, a window assembly, and a vibrating screen 9; the threshing assembly has a front half shaft 15, a spiral cone feeder 16, a threshing drum 3. Concave screen 4, top cover 2, the front end of the spiral conical feeder 16 is connected to the front half shaft 15 through a flange, the rear end is coaxially rigidly connected to one end of the threshing drum 3, and the front end of the threshing drum 3 The other end is fixedly connected with the rear half shaft 17, and the front half shaft 15 and the rear half shaft 17 are installed on the frame through bearings, so that the front and rear half shafts can freely rotate on the frame, and the concave plate screen 4 is installed On the frame 1, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com