Method and device for removing iron in fluid

A fluid and fluid outlet technology, applied in the field of magnetic separation methods and devices, can solve the problems of large clean water, consumption, and poor cleaning effect, and achieve the effects of convenient and reliable use, low manufacturing cost, and recovery ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

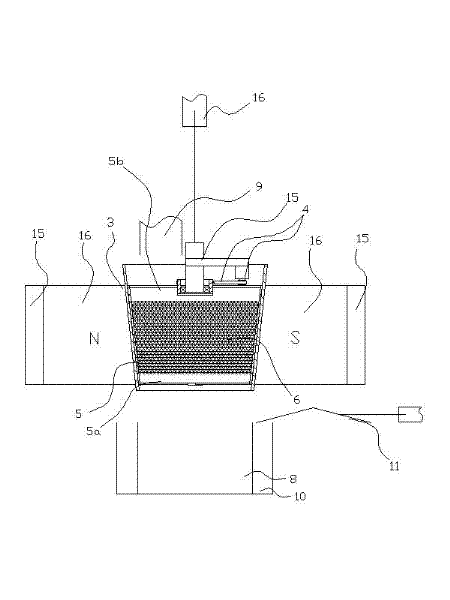

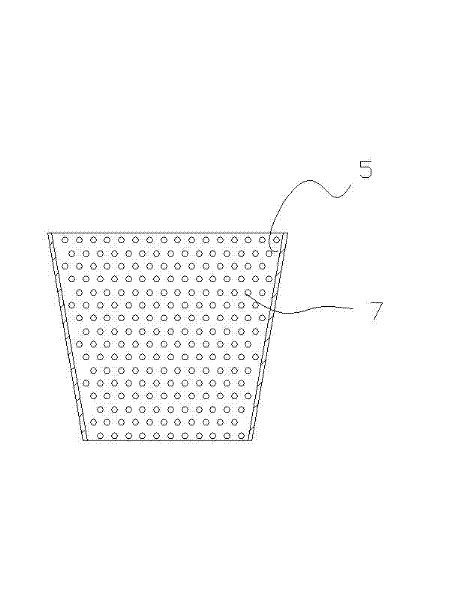

[0025] Embodiment 1: as figure 1 , 2 As shown, the fluid iron removal device of the present invention is realized in this way, comprising the magnetic field 1 formed between the north and south permanent magnet poles 16 with armor 15, the passage 3 arranged in the magnetic field, the passage 3 arranged in the passage 3 with The non-magnetic conductive cylinder 5 of the rotating power mechanism 4, the soft magnetic medium 6, the frame 15, and the lifting power mechanism 16 arranged in the non-magnetic conductive cylinder 5, the passage 3 is conical and non-magnetic, and the corresponding non-magnetic conductive cylinder 5 is conical, and the non-magnetic conductive cylinder 5 is rotated and arranged on the frame 15, and the frame 15 is connected with the lifting power mechanism 16, such as image 3 As shown, several perforations 7 are arranged on the sides of the non-magnetic cylinder 5, and the perforations 7 are distributed in the form of a net on the sides of the non-magnet...

Embodiment 2

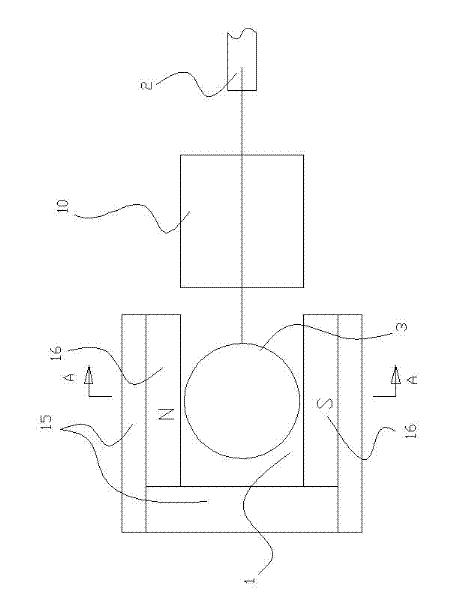

[0029] Embodiment 2: as Figure 4 , 5 , 3, on the basis of embodiment 1 during the present embodiment, the channel 3 is a straight cylindrical non-conductive channel 3 driven in and out of the magnetic field 1 by the overpower mechanism 2, and the non-magnetic tube 5 is arranged on the straight cylindrical non-conductive There is a straight cylindrical non-magnetic conductive cylinder 5 with a rotary power mechanism 4 in the magnetic passage 3, and the diameter of the straight cylindrical nonmagnetic conductive passage 3 is larger than the outer diameter of the straight cylindrical nonmagnetic conductive cylinder 5. In the straight cylindrical nonmagnetic conductive passage 3 A support frame 17 is arranged inside, and the straight cylindrical non-magnetic conduction cylinder 5 is rotatably arranged on the support frame 17, such as Figure 5 As shown, several perforations 7 are arranged on the sides of the non-magnetic cylinder 5, and the perforations 7 are distributed in a me...

Embodiment 3

[0032] Embodiment 3: as Image 6 As shown, this embodiment is based on Embodiment 1, and uses electromagnetic poles to replace the north-south permanent magnet poles 16 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com