Method and system for estimating material property

A material performance and evaluation system technology, applied in the analysis of materials, strength properties, special data processing applications, etc., can solve the problem of heavy testing workload, and achieve the effect of avoiding huge testing workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

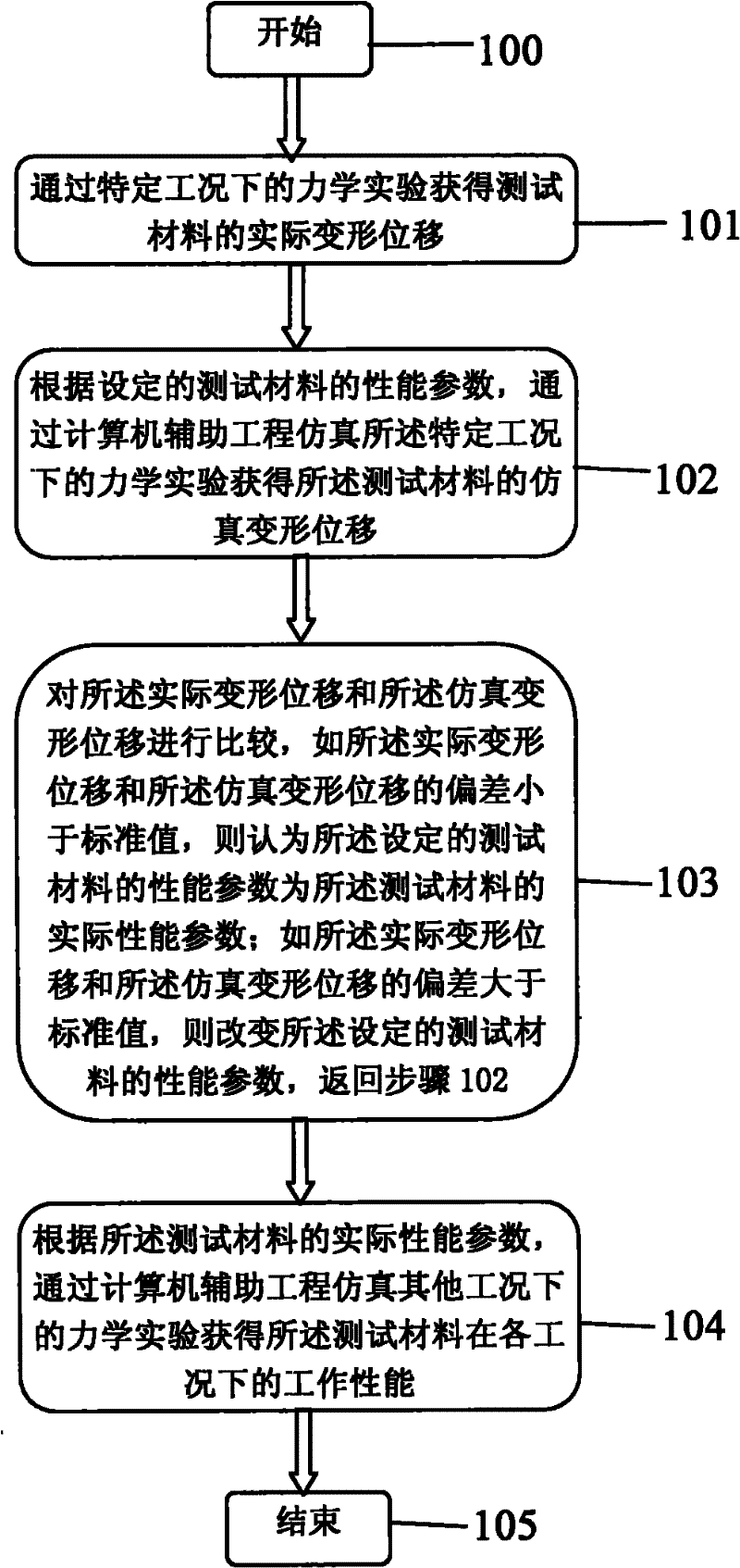

[0052] The purpose of the present invention is to quantify the mechanical performance parameters of the test material through the combination of compression deformation experiment and computer aided engineering calculation. As long as there are no restrictions on the selection of materials in the linear elastic range and the initial plastic yield stage of the metal, any self-made standard sample can be selected for testing. The implementation process is not limited to any process of experiment and simulation, but from the mutual Obtaining the real apparent mechanical performance parameters of the material during the calibration process is of great significance for the strength design and reliability analysis of components.

[0053] 1. Tooling structure design and standard sample production

[0054] The experimental tooling mainly completes the synchronous collection of contact force data and displacement data in mechanical testing experiments. The structural parts are as follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com