Method for preparing low-polymerization-degree polyformaldehyde dialkyl ether from petroleum fractions and application

A technology of formaldehyde dialkyl ether and low degree of polymerization, which is applied in the petroleum industry, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of high degree of polymerization and low effective content, and achieve simple preparation process, The effect of increasing the output ratio and reducing the olefin content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

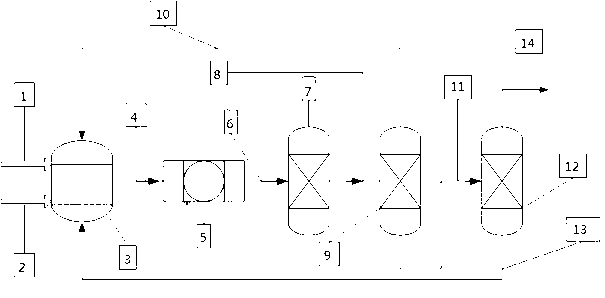

Image

Examples

Embodiment 1

[0047] Preparation of Polyoxymethylene Dialkyl Ether C with Low Polymerization Degree from Petroleum Fractions n h 2n+1 O(CH 2 O) m C n h 2n+1 The method is:

[0048] In the batch type autoclave, add petroleum C sequentially according to the molar ratio of 2:4 5 1. Industrial formaldehyde with a formaldehyde content of 37%. The water contained in industrial formaldehyde can be used as an initiator to participate in the reaction. Select p-toluenesulfonic acid, which accounts for 2% of the total weight of the reactants, as a catalyst and put it into the reaction kettle, and fill it with nitrogen replacement reaction The air in the kettle, the initial pressure in the reactor is controlled to 0.2Mpa, and the reaction temperature is maintained at 70-90°C for 10 hours with stirring at 100rpm until the components are balanced. After the reaction is completed, go through the above-mentioned extraction and separation process steps, separate and finally collect the fraction at 15...

Embodiment 2

[0051] Preparation of Polyoxymethylene Dialkyl Ether C with Low Polymerization Degree from Petroleum Fractions n h 2n+1 O(CH 2 O) m C n h 2n+1 The method is:

[0052] In the batch type autoclave, add petroleum C sequentially according to the molar ratio of 4:1:4 4 , methanol, a mixture of anhydrous low-polymerization paraformaldehyde and anhydrous formaldehyde, wherein methanol is used as an initiator to trigger the reaction, and a strong acidic cation exchange resin accounting for 5% of the total weight of the reactants is selected as a catalyst and put into the reaction kettle together , filling the inert gas to replace the air in the reactor, controlling the initial pressure in the reactor to 0.3Mpa, and maintaining a constant temperature of 90-120° C. for 10 hours under stirring at 100 rpm. After the reaction is completed, go through the above-mentioned extraction and separation process steps, separate and finally collect the fraction at 150-340° C., and refine the ...

Embodiment 3

[0055] Preparation of Polyoxymethylene Dialkyl Ether C with Low Polymerization Degree from Petroleum Fractions n h 2n+1 O(CH 2 O) m C n h 2n+1 The method is:

[0056] In the intermittent high-pressure reactor, add catalytically cracked light gasoline 30-70°C distillate, methanol and anhydrous paraformaldehyde in a molar ratio of 3:1:2. Methanol is used as an initiator to trigger the reaction. Select the total weight of the reactants. The mixture of 0.1% trifluoromethanesulfonic acid and p-toluenesulfonic acid is put into the reactor together as a catalyst, and the air in the nitrogen replacement reactor is charged, and the initial pressure in the reactor is controlled at 0.6Mpa, and kept under stirring at 100rpm. 50-70°C constant temperature reaction for 10 hours. After the reaction is completed, go through the above-mentioned extraction and separation process steps, separate and finally collect the fraction at 150-340° C., and refine the obtained product. According to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com