On-site certificate card manufacturing equipment and method

A technology for ID cards and equipment, applied in printing devices, printing, printing processes, etc., can solve the problems of inability to reflect the service efficiency of convenient and beneficial services, low flexibility, and restrictions on the application of card-type certificates, and achieve a simple and easy-to-understand certification process. , easy to transport and store, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

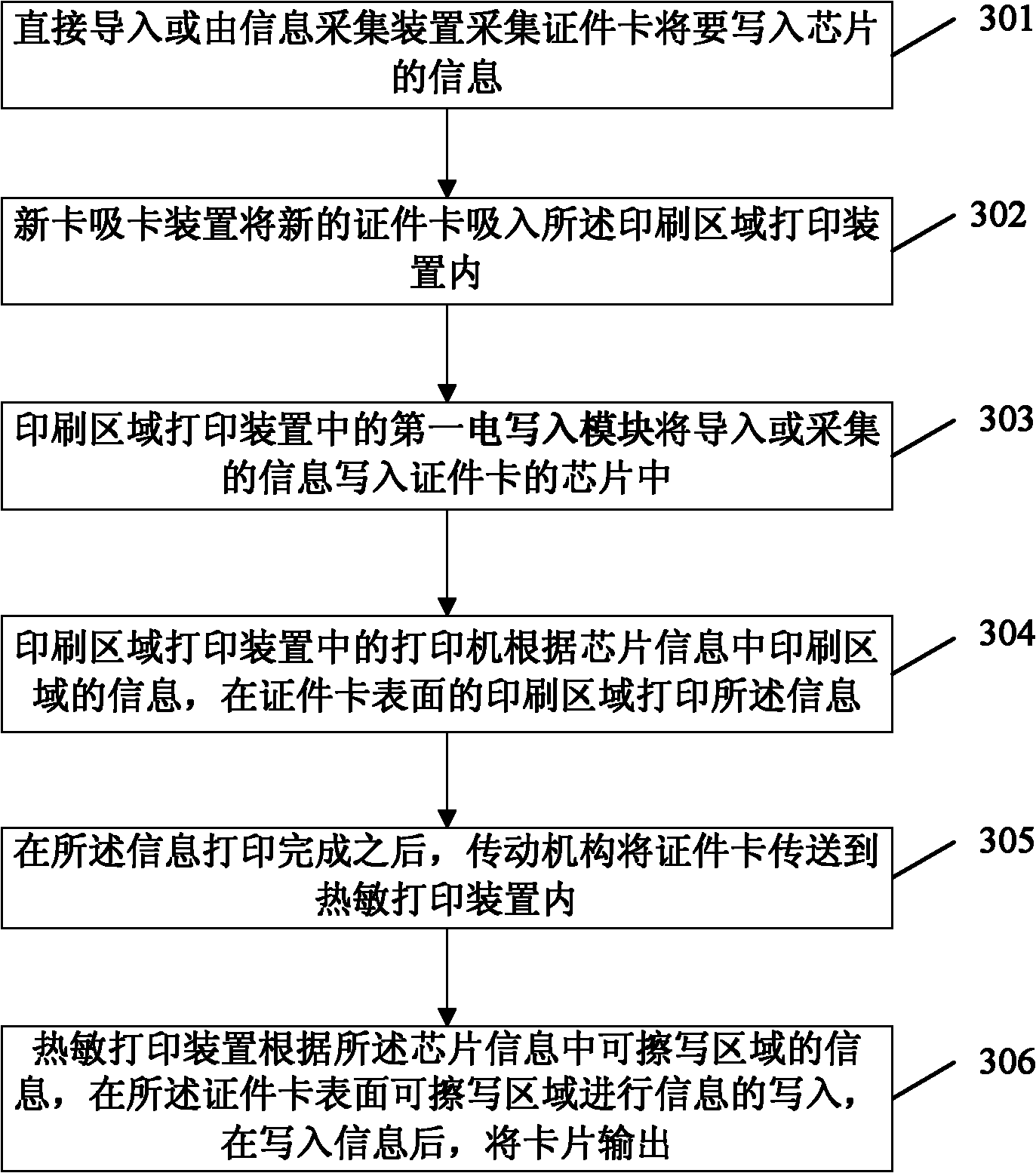

Embodiment 1

[0044] see figure 2 , which is a frame structure diagram of the equipment for producing a document card according to an embodiment of the present invention. As shown in the figure, the equipment includes a chassis, an information collection device 21 arranged outside the chassis, and a new card suction device 22 arranged in the chassis , the printing area printing device 23, the transmission mechanism 24, the thermal printing device 25 and the control assembly 26 that are provided with the first electrical writing module and the printer inside; The new card suction device 22, the printing area printing device 23, the transmission mechanism 24 is connected to the thermal printing device 25 in turn, and the control assembly 26 is respectively connected to the information collection device 21, the new card suction device 22, the printing area printing device 23, the transmission mechanism 24 and the thermal printing device 25 through lines.

[0045] In specific implementation: ...

Embodiment 2

[0070] see Figure 5 , is a schematic diagram of the three-dimensional structure of the on-site certificate card production equipment according to the embodiment of the present invention. It should be noted that, Figure 6 It is a schematic diagram of the chassis structure of the on-site certificate card production equipment according to the embodiment of the utility model. Due to the different angles of the schematic diagram, some parts are visible, and some parts are non-visible. For non-visible parts, it is mainly through text Describe and express the positional relationship of non-visual components, such as Figure 5 As shown, the production equipment includes:

[0071] Barcode reader 1, ID card reader 2 and ID card reader 3, ID card reader 2 and ID card reader 3 form a smart card reader, and the smart card reader and barcode reader 2 are set on the workbench to form a The information collection device 21 in Embodiment 1 is mentioned, and for its specific description, pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com