Method for detecting curvature radius of optical spherical surface

A technology of curvature radius and detection method, which is applied in the direction of optical devices, measuring devices, instruments, etc., can solve problems such as measurement and error of spherical mirrors with large curvature radii, and achieve simple data processing and mathematical operations, short measurement time, and experimental results. Simple and easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

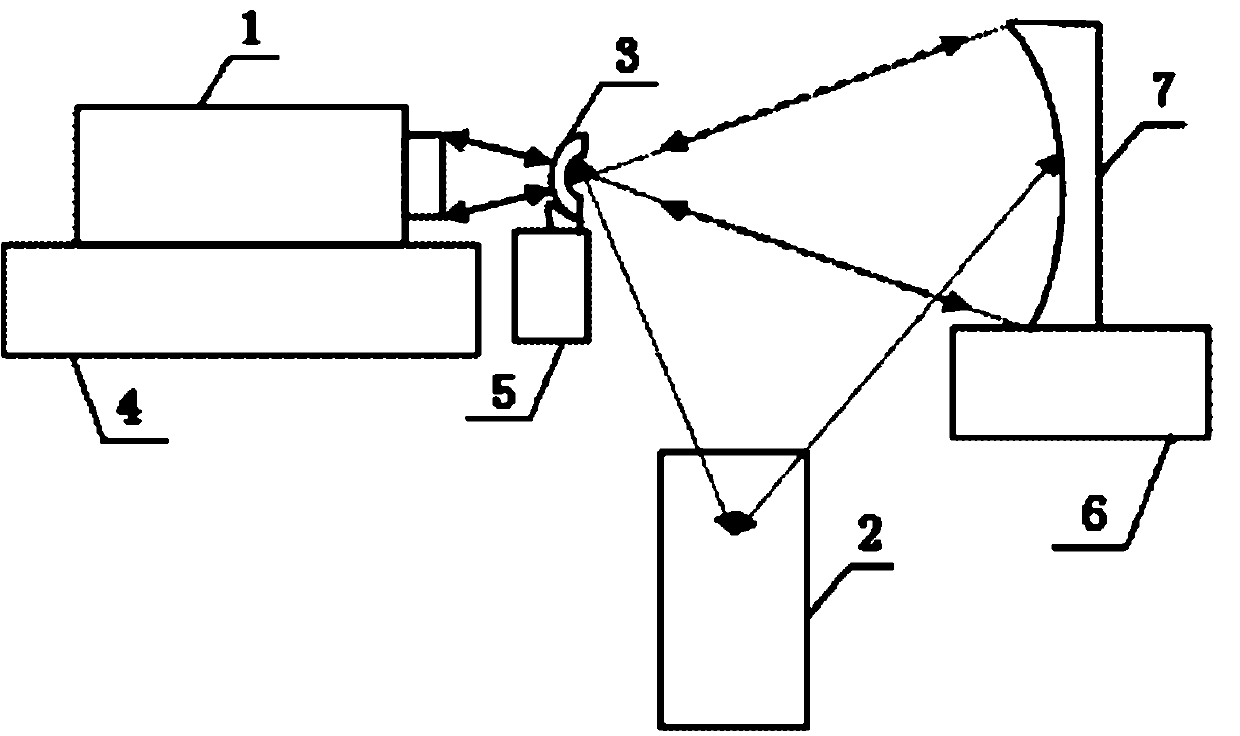

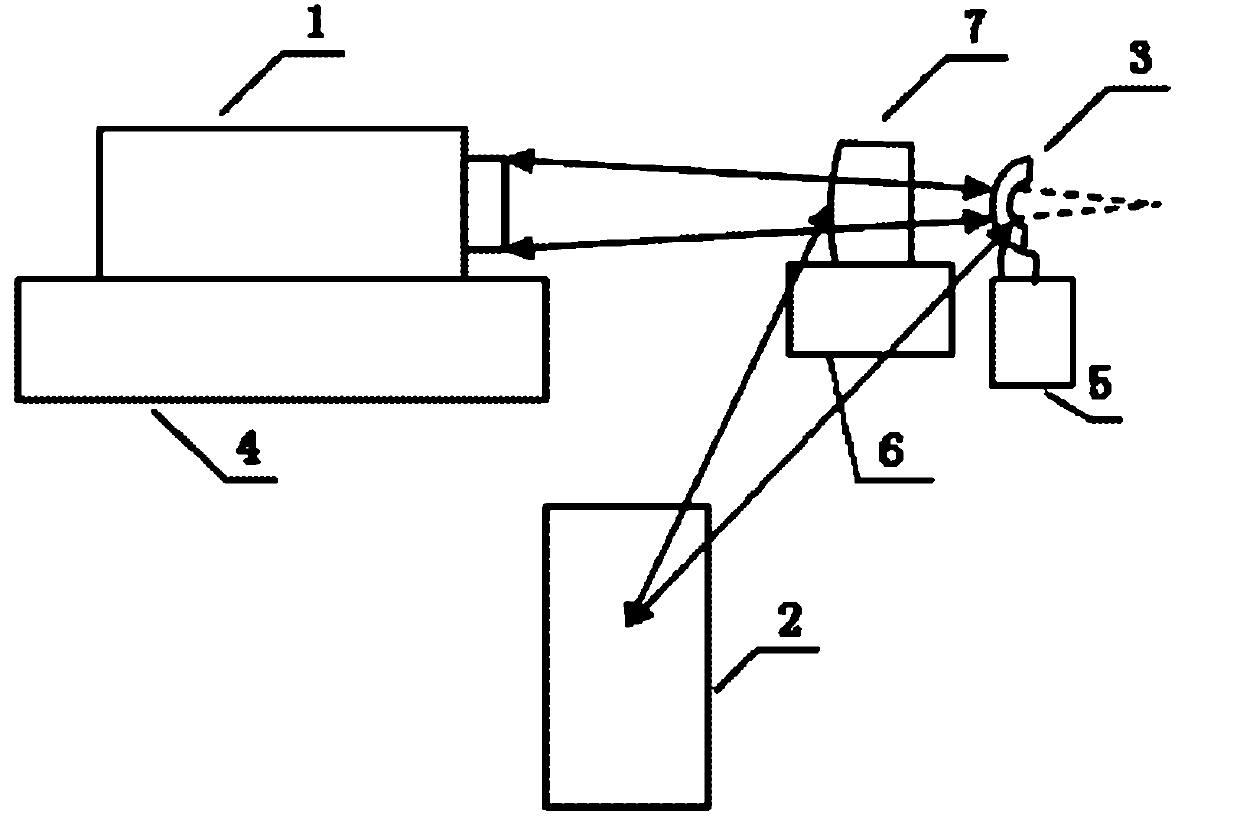

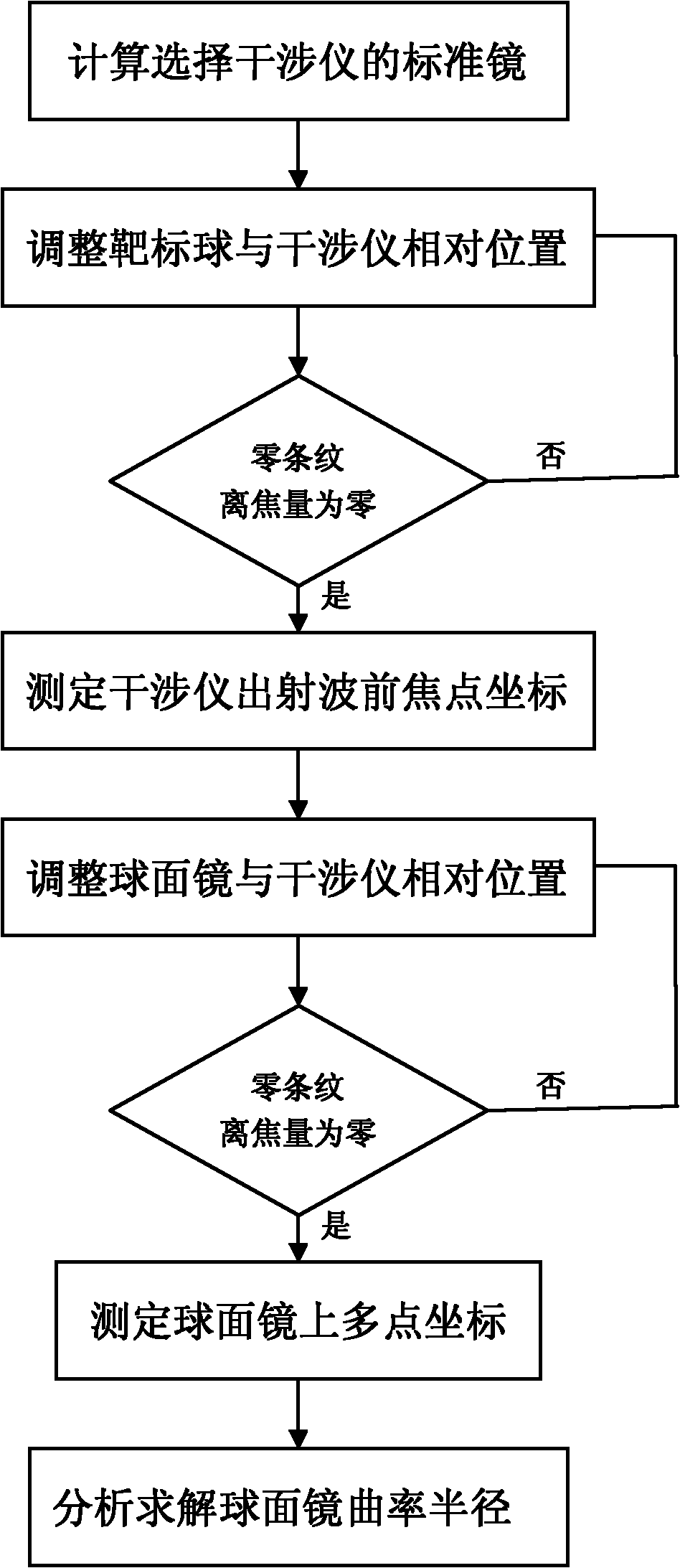

[0017] Specific implementation mode 1. Combination Figure 1 to Figure 3 Describe this embodiment, a kind of detection method of the radius of curvature of an optical spherical mirror, this method is realized by the following steps:

[0018] Step 1. Adjust the relative position of the target ball 3 and the interferometer 1, and judge whether the center of curvature of the target ball 3 coincides with the wavefront focus of the interferometer 1 exiting the spherical mirror to be tested; if yes, then perform step 2; if not, Then continue to adjust the relative position of the target ball 3 and the interferometer 1;

[0019] Step 2, the laser tracker 2 measures the center of curvature coordinates of the target ball 3, and the center of curvature coordinates of the target ball 3 are the coordinates of the focal point of the outgoing wavefront of the interferometer 1;

[0020] Step 3, repeatedly adjust the relative position of the spherical mirror 7 to be measured and the interfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com