Airplane wingtip device

A wingtip and aircraft technology, applied in the direction of wing shape, heat reduction structure, etc., can solve the problems of large bending moment, increase of structural weight, influence of aircraft flutter characteristics, etc., to reduce eddy current strength, reduce structural weight, flutter Features with little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

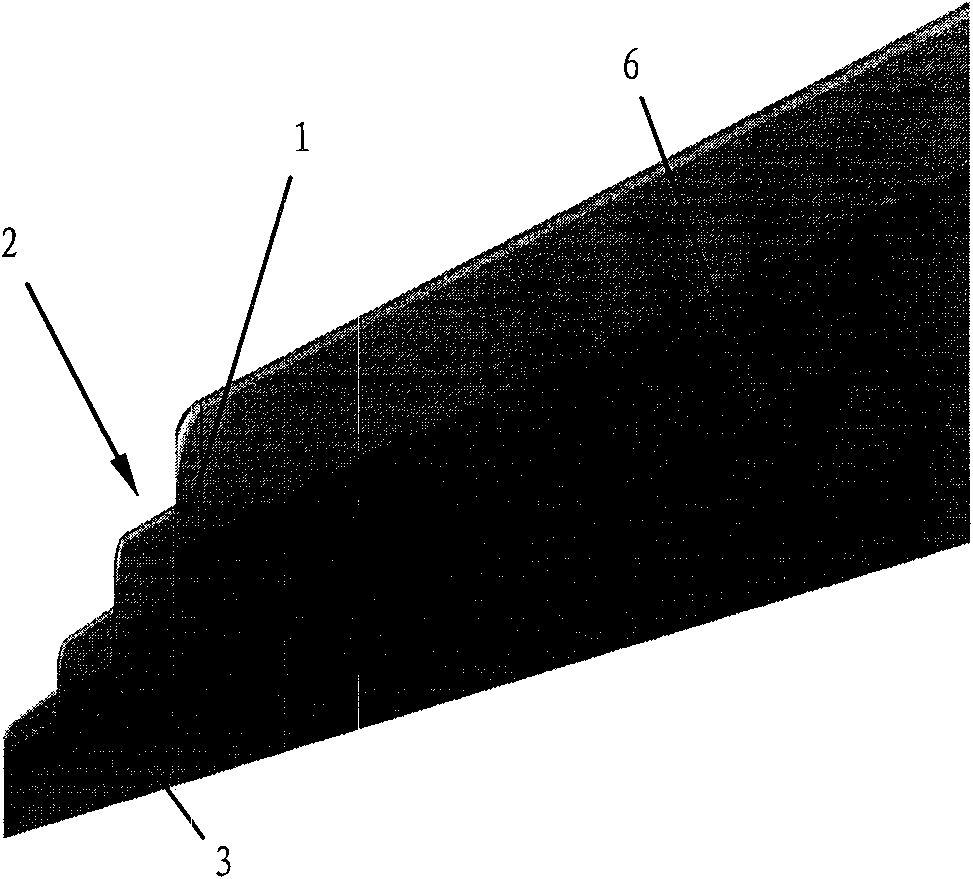

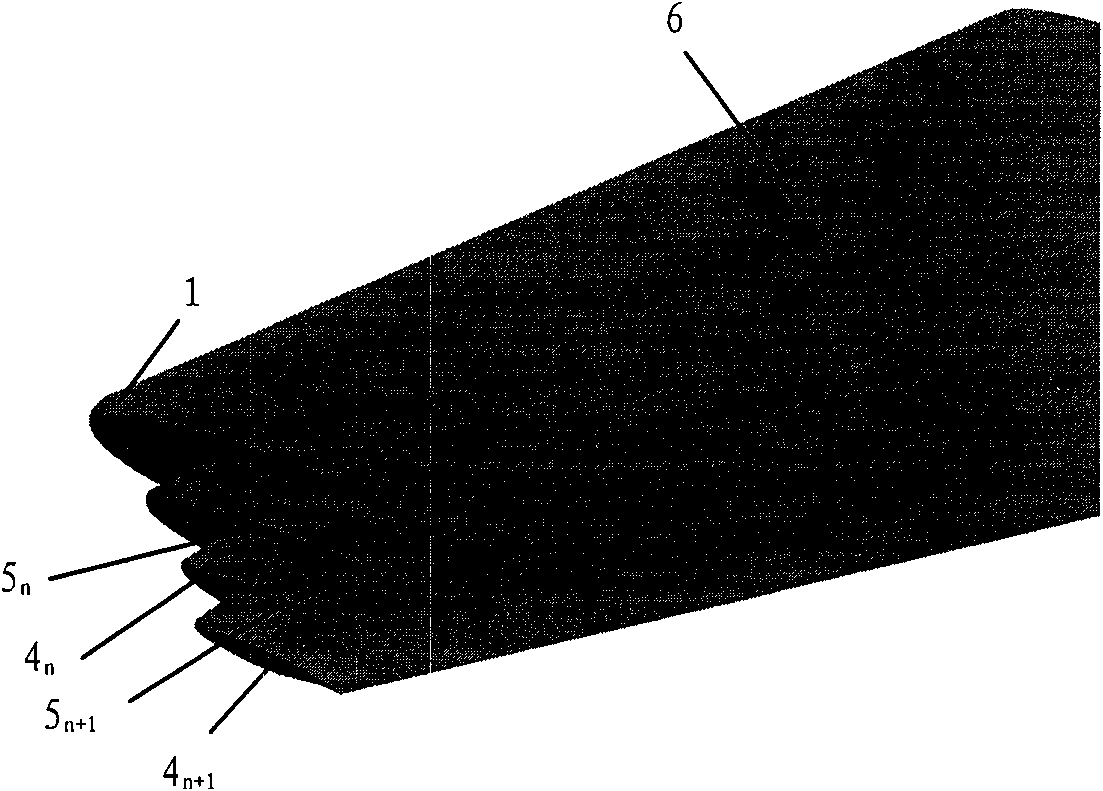

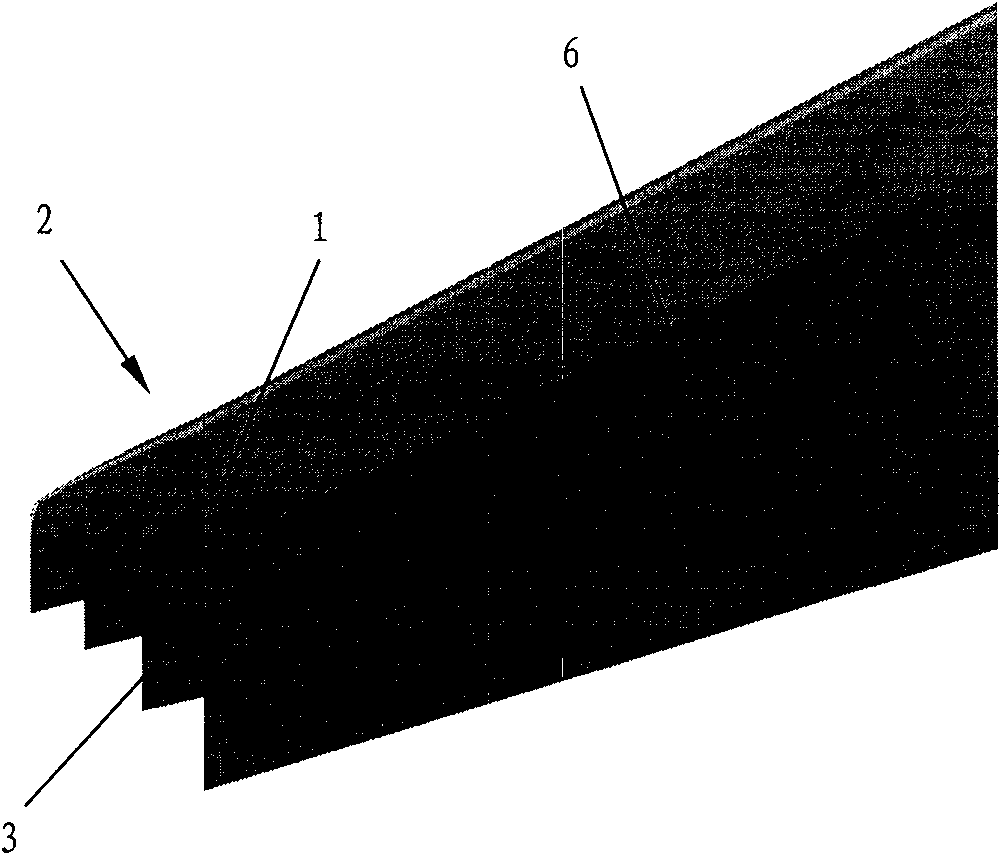

[0044] Such as figure 1 with figure 2 As shown, in one embodiment of the present invention, the aircraft wingtip device is in a multi-step shape, which includes a transition portion 1 and a wingtip portion 2, and the inner end of the transition portion 1 is connected to the far end of the aircraft wing 6 , the connection between the outer end of the transition portion 1 and the wing tip 2, wherein the wing tip includes a plurality of wing tip segments 3 n , each wingtip segment includes wingtip 4 n and wing root 5 n , the first wingtip segment 3 1 wing root 5 1 Connected to the outer end of the transition portion 1 and aligned with the trailing edge of the outer end of the transition portion 1, the n+1th wing tip segment 3 n+1 wing root 5 1 Located at the nth wingtip segment 3 n Wingtip 4 n on, and the n+1th wingtip segment 3 n+1 wing root 5 1 The chord length is less than the nth wingtip segment3 n Wingtip 4 n Chord length, where n>0. Additionally, if figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com