Die extending structure and die extending method using hydraulic moveable male die

A drawing die and hydraulic pressure technology, which is applied in the field of sheet metal deep drawing and forming dies, can solve problems such as sheet metal drawing and cracking, and achieve the effects of preventing cracking, increasing flow force, and increasing bonding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The drawing die structure and drawing method of the present invention using a hydraulically movable punch will be described in detail below in conjunction with the embodiments and the accompanying drawings.

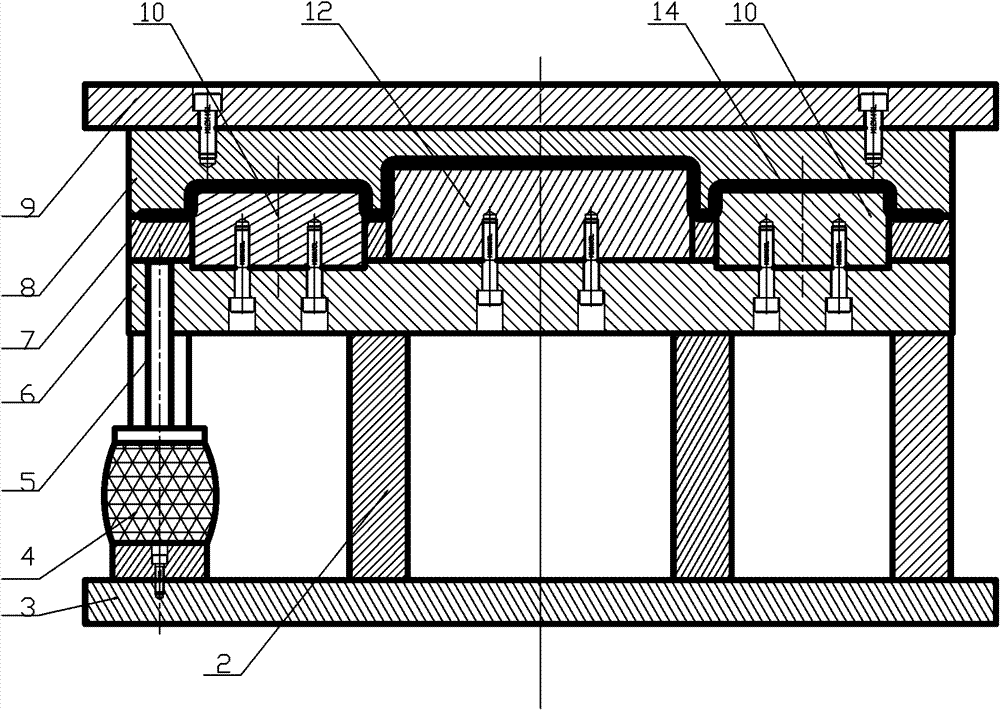

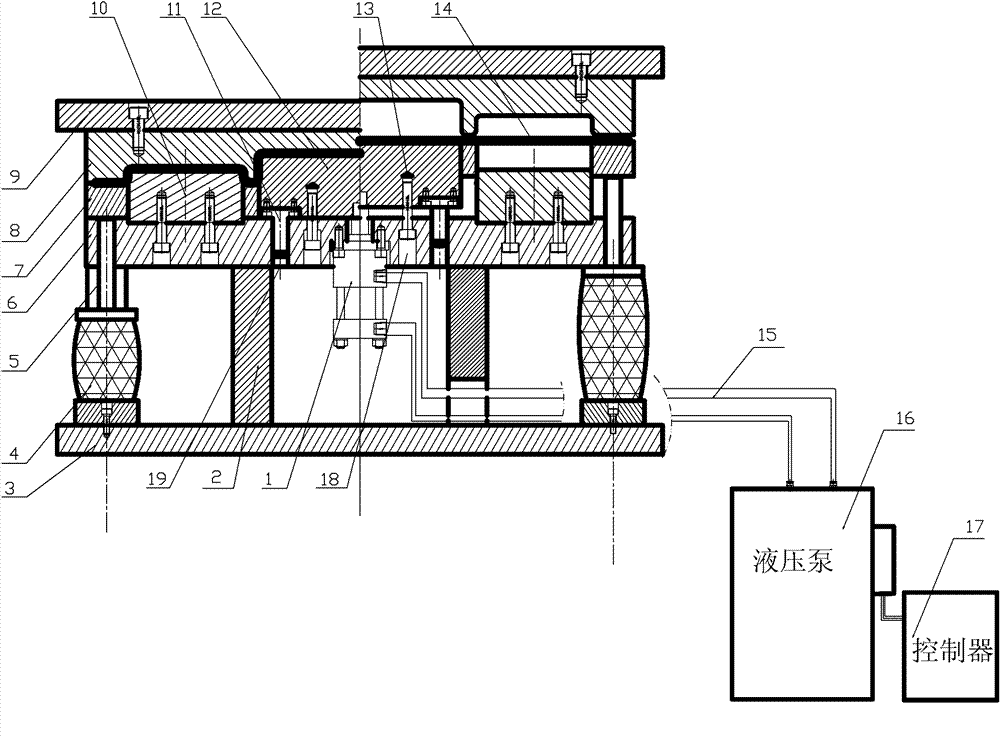

[0020] Such as figure 2 As shown, the drawing die structure utilizing the hydraulic pressure active punch of the present invention includes: a lower mold base 3, more than two elastic polyurethane support members 4 fixed on the periphery of the lower mold base 3, fixed on the lower mold base 3 More than two supporting plates 2, the punch backing plate 6 supported on the elastic polyurethane support 4 and the supporting plate 2, the blank holder 7 on the punch backing 6, the blank holder 7 embedded in the blank holder 7 The movable punch 12 and the small punch 10 are located on the blankholder 7, the movable punch 12 and the small punch 10 and are formed with the concave die 8 corresponding to the movable punch 12 and the small punch 10, and are fixed on the The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com