Electric heater with omega tube

An electric heating device and heating element technology, applied in the direction of the shape of the heating element, can solve problems such as high cost, and achieve the effect of reliable heat distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In all figures, the same reference numerals are used for the same components of the same embodiment.

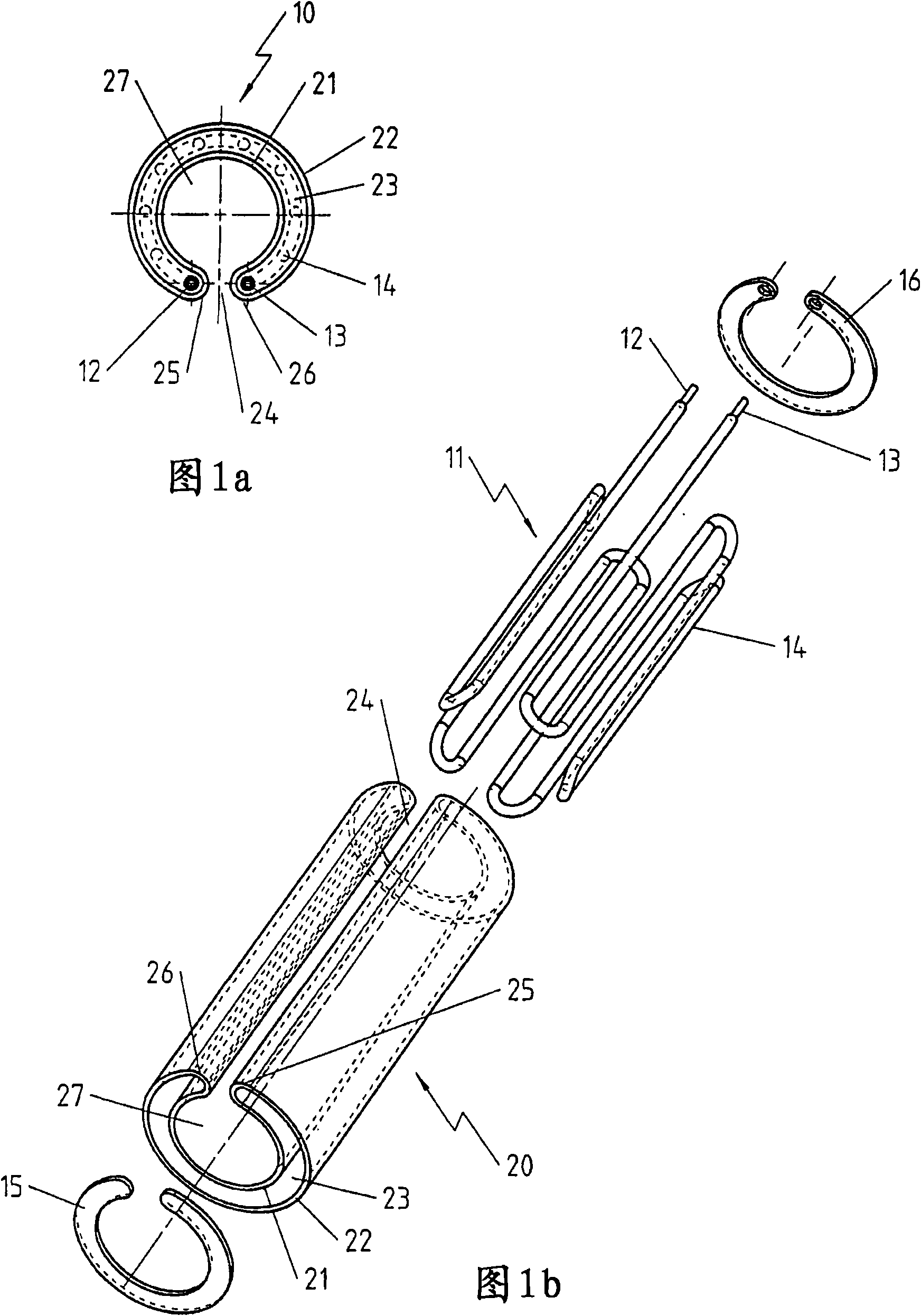

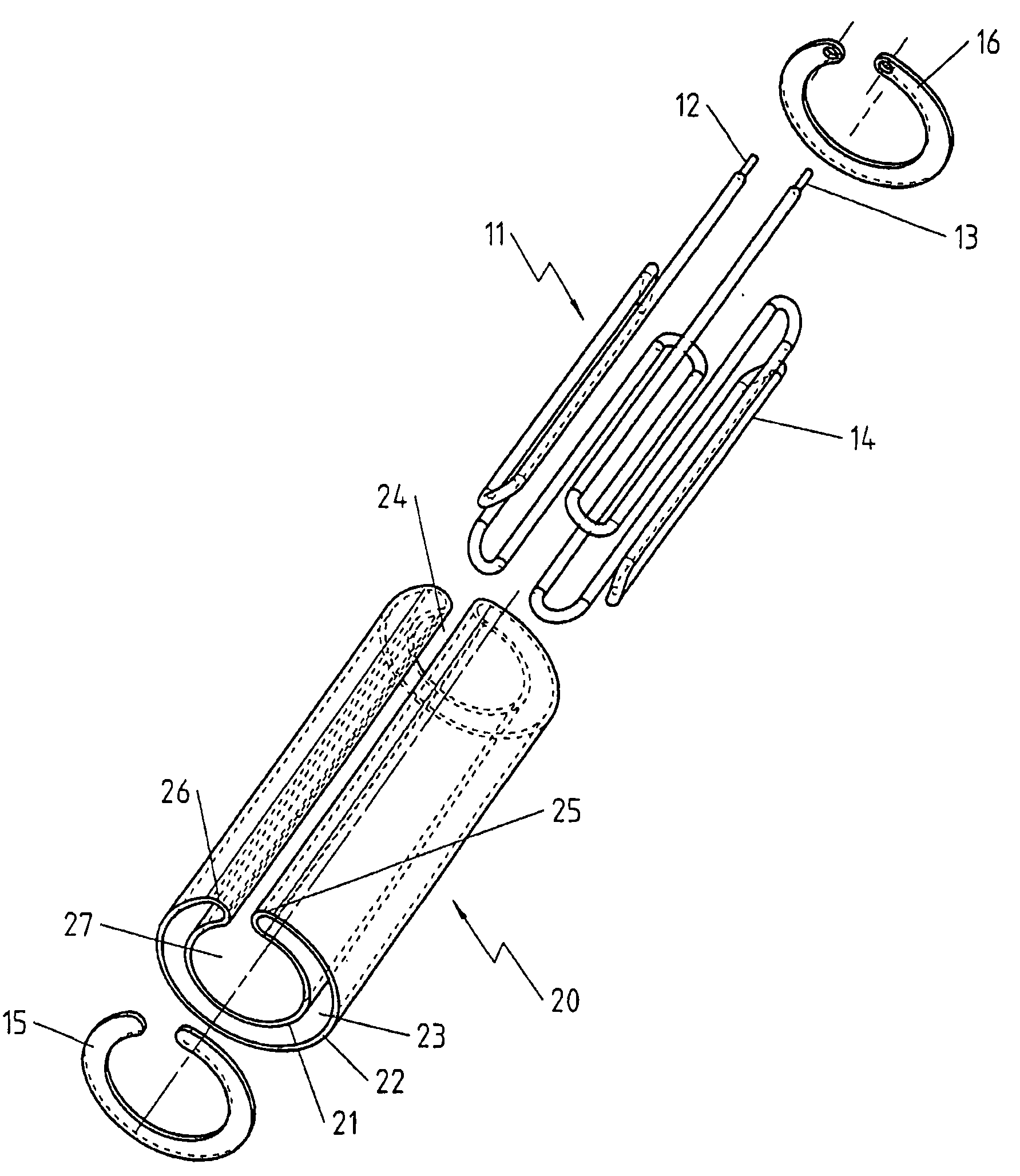

[0034] Figure 1a A sectional view of an electric heating device according to an embodiment of the present invention is shown (the section is perpendicular to the extending direction of the electric heating device). The electric heating device 10 has a double-walled tube 20 with an inner wall shell 21 and an outer wall shell 22 , between which a space 23 is defined. The inner wall shell 21 and the outer wall shell 22 are radially symmetrical in the section shown and are arranged coaxially with one another, but other geometries are also possible. The inner wall shell 21 and the outer wall shell 22 are penetrated by a gap 24 . Space 23 passes through walls 25, 26 (in Figure 1a The center is bent toward the gap 24) and the gap is spaced. The inner wall shell 21 and the part of the gap which passes through the inner wall shell 21 enclose a space 27 in which, for example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com