Vibration detection platform

A technology of vibration detection and workbench, which is applied in the field of detection and can solve problems such as inability to withstand vibration and reliability evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

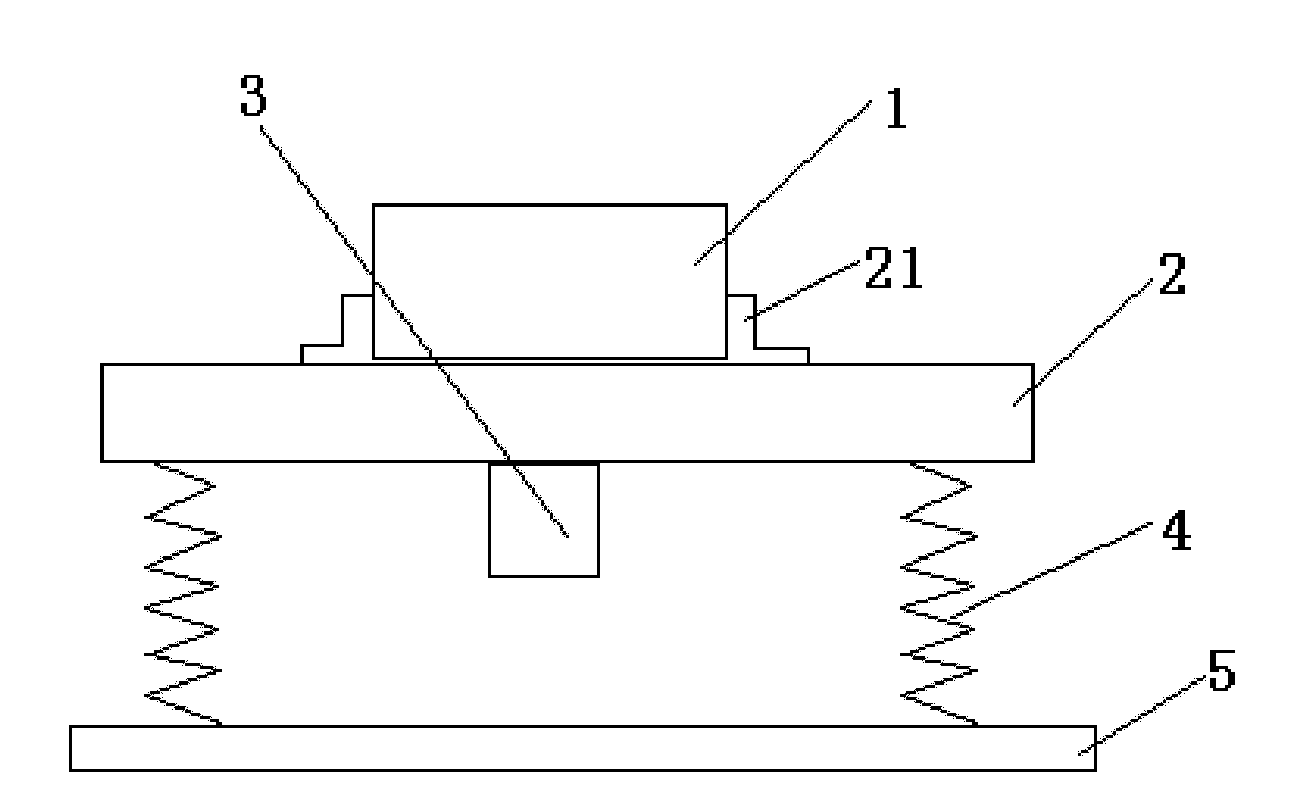

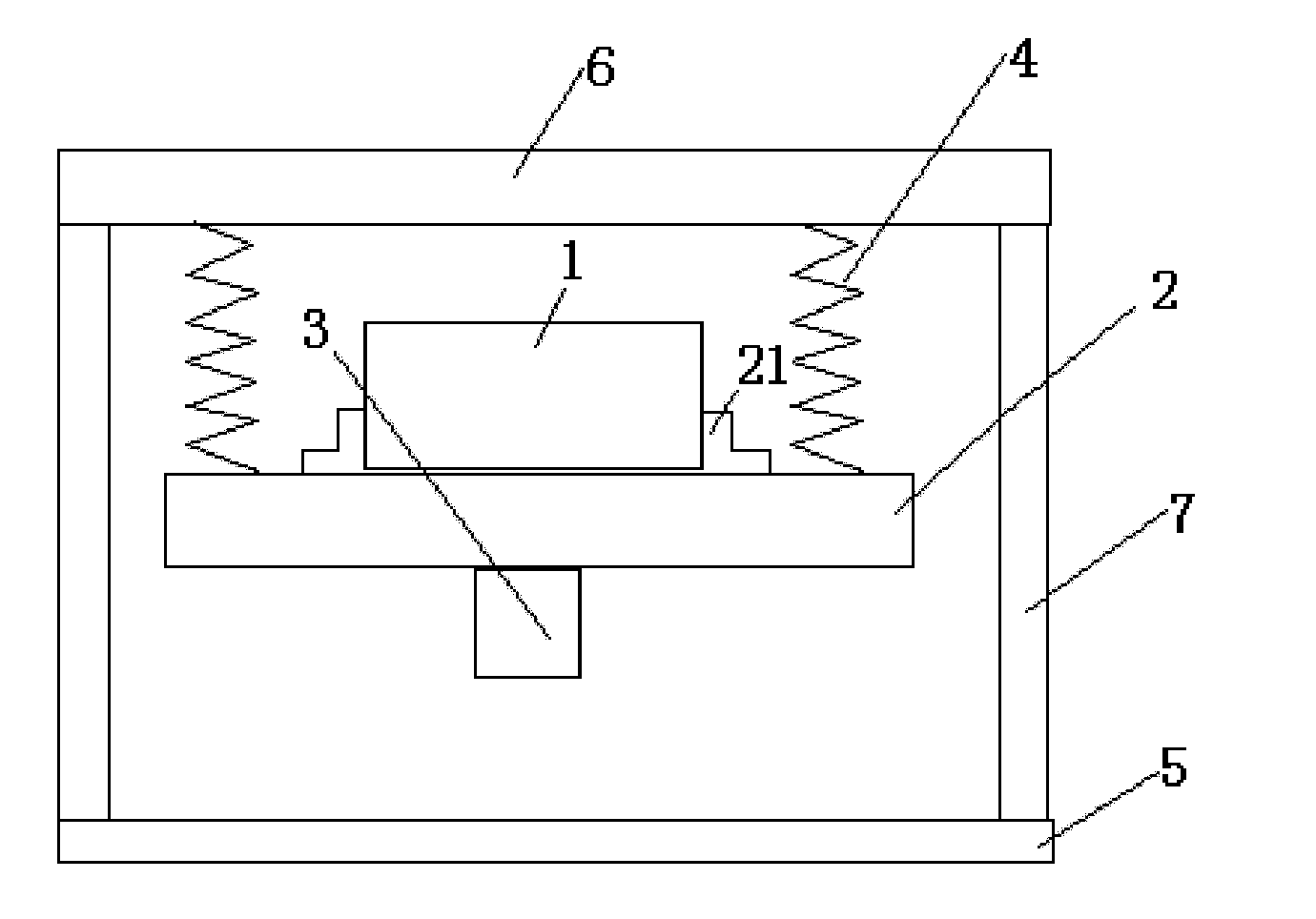

[0020] like figure 2 As shown, the vibration detection table of the present invention includes a base 5, a vibrator 3, a workbench 2 with a locking device 21 on the upper surface, 5 tension springs 4, and a support; the vibrator 3 is fixed on the working Below the platform 2, the product under test 1 is fixed on the workbench 2; the bracket is composed of a horizontal plate 6 and a column 7; the column 7 is vertically fixed on the base 5, and its upper end is fixedly connected with the horizontal plate 6; the tension spring 4 One end of it is connected with the horizontal plate 6, and the other end is connected with the workbench 2, so that the workbench 2 is suspended above the base 5.

Embodiment 2

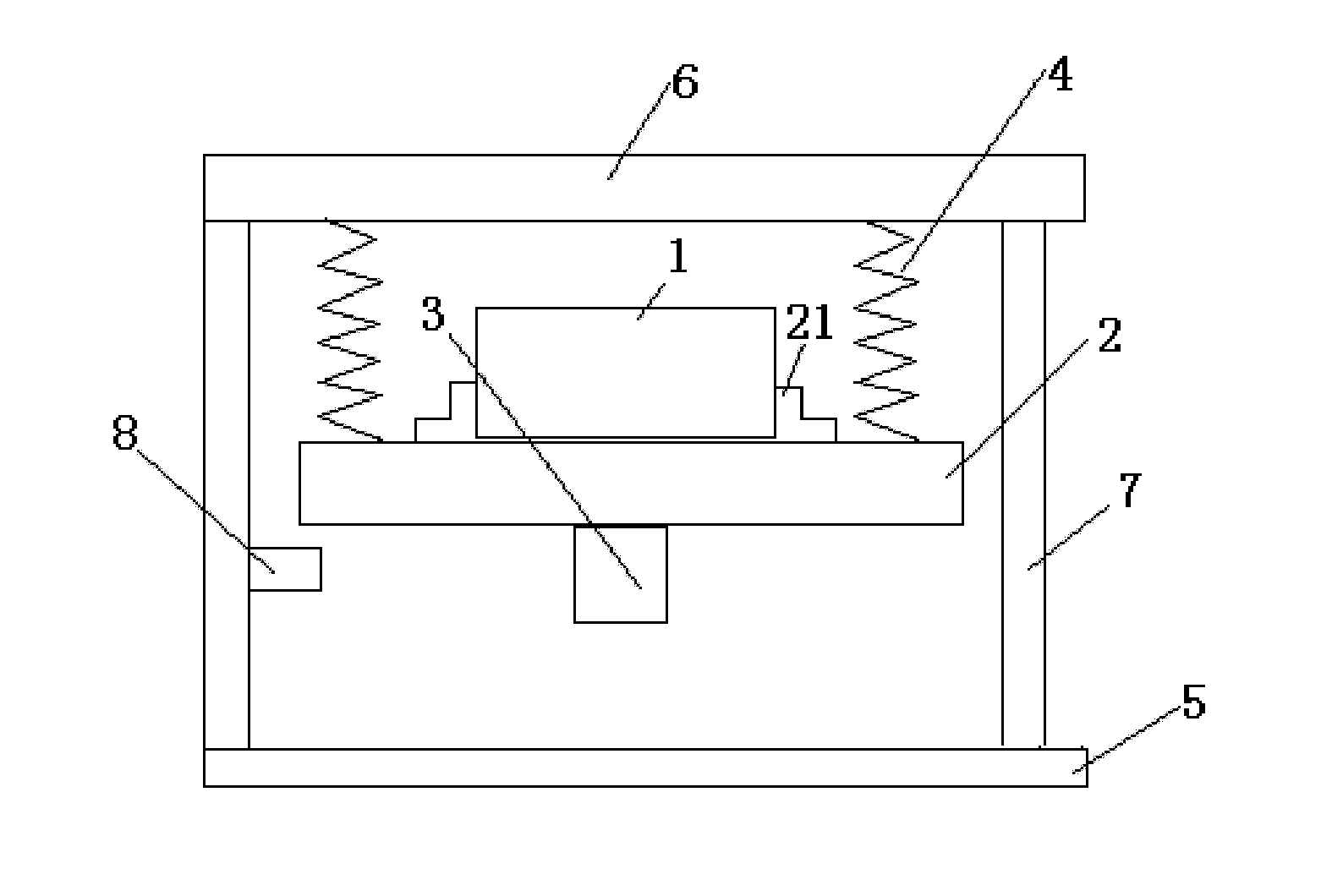

[0022] like image 3 As shown, the vibration detection table of the present invention includes a base 5, a vibrator 3, a workbench 2 with a locking device 21 on the upper surface, 4 tension springs 4, a support, and a limit device 8; The instrument 3 is fixed under the workbench 2, and the product under test 1 is fixed on the workbench 2; the bracket is composed of a horizontal plate 6 and a column 7; the column 7 is vertically fixed on the base 5, and its upper end is fixedly connected with the horizontal plate 6 One end of the tension spring 4 is connected with the horizontal plate 6, and the other end is connected with the workbench 2, so that the workbench 2 is suspended above the base 5; When the surface is in contact with the limiting device 8, the stress on the extension spring 4 does not exceed its elastic limit.

Embodiment 3

[0024] like Figure 4 As shown, the vibration detection table of the present invention includes a base 5, a vibrator 3, a workbench 2 with a locking device 21 on the upper surface, a tension spring 4, a support, and a limit device 8; the vibrator 3 is fixed under the workbench 2, and the product under test 1 is fixed on the workbench 2; the bracket is composed of a horizontal plate 6 and a column 7; the column 7 is vertically fixed on the base 5, and its upper end is fixedly connected with the horizontal plate 6; One end of the tension spring 4 is connected with the column 7, and the other end is connected with the workbench 2, so that the workbench 2 is suspended above the base 5; the limit device 8 is fixed on the column 7, and when the lower surface of the workbench 2 When the limit device 8 is in contact, the stress on the extension spring 4 does not exceed its elastic limit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com