Fixation-free connection way of motor of small washing machine

A connection method and washing machine technology, applied in the field of washing machines, can solve the problems such as the inability to reduce the size of the washing machine, the unreasonable installation method of the motor, and the difficulty in disassembly, and achieve the effects of expanding the operable space, running stably, and realizing the degree of tightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

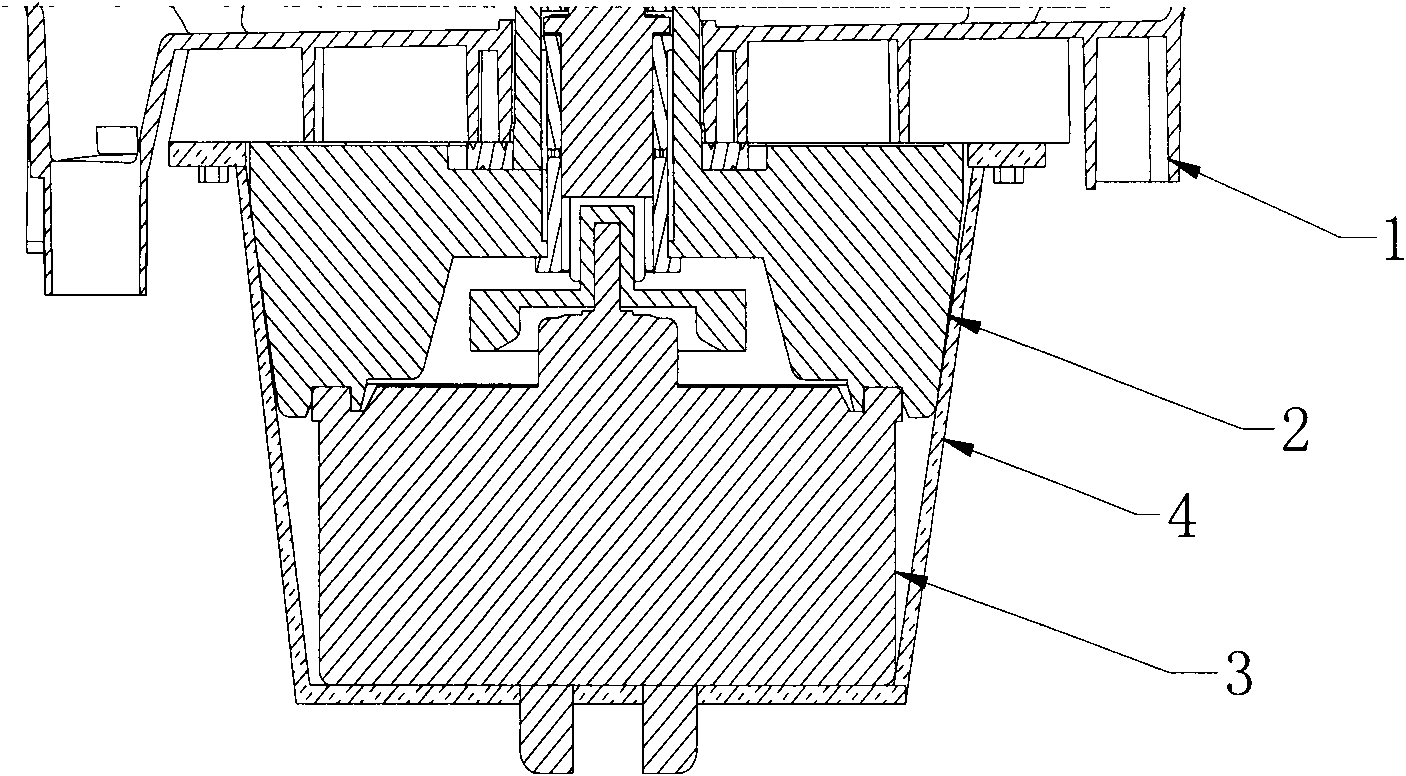

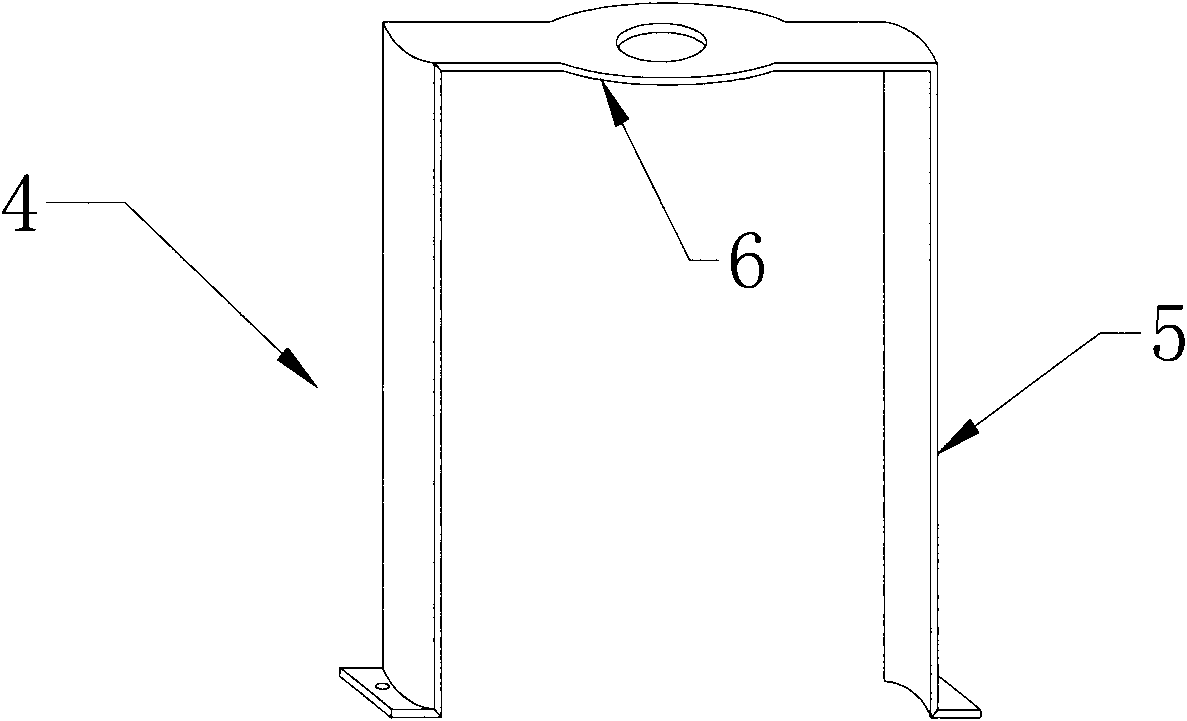

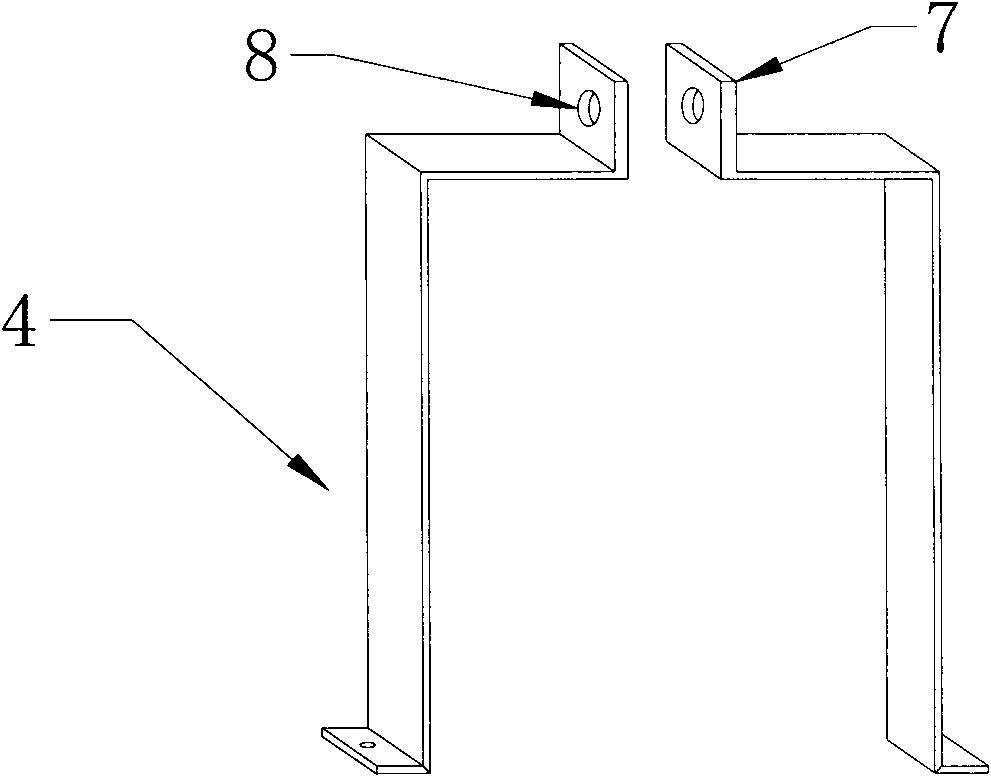

[0018] Such as figure 1 As shown, the motor 3 and the bearing housing 2 are successively superimposed on the bottom of the outer tub 1 of the small washing machine, and there is no fixed connection between the components, only the meshing relationship. The fixing device 4 adopts a slat-shaped U-shaped structure, and is fixed on the bottom of the outer tub of a small washing machine by using two ends, so that the motor and the bearing seat are tightly pressed on the bottom of the outer tub, and the fixing device simultaneously realizes the level of the motor and the bearing seat. The fixing in the vertical direction, and the concave-convex meshing structure provided among the motor, the bearing seat, and the bottom of the outer barrel also strengthen the stability between the various components. The fixing points of the fixing device are all located in places with a wide field of view, which avoids the problems of different angles and specific spatial positions when each compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com