Cutting tool

A technology of cutting tool and fixed blade, applied in metal processing and other directions, can solve the problems of inconvenient use, cumbersome operation, complex cutting tool structure, etc., and achieve the effect of simplified structure and convenient operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

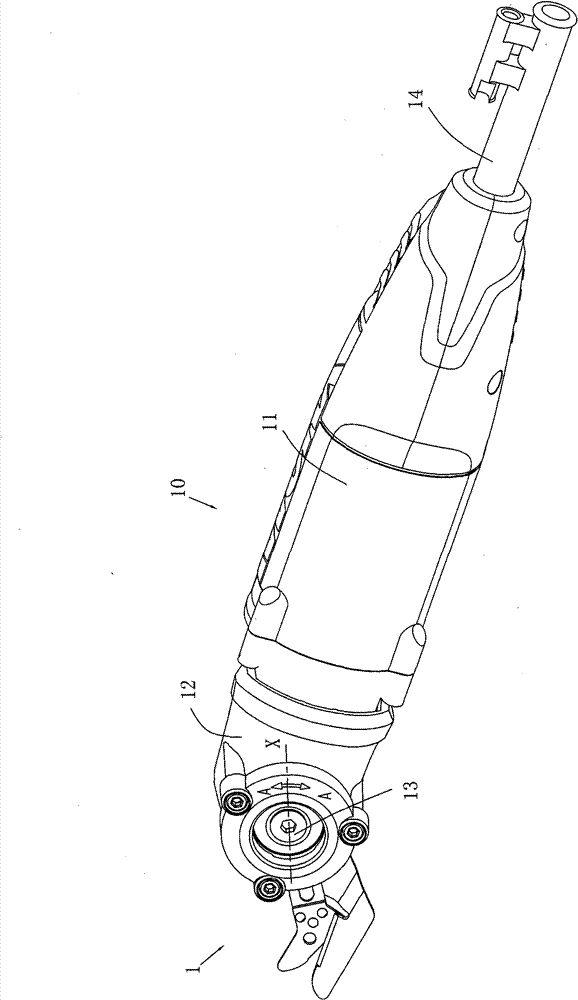

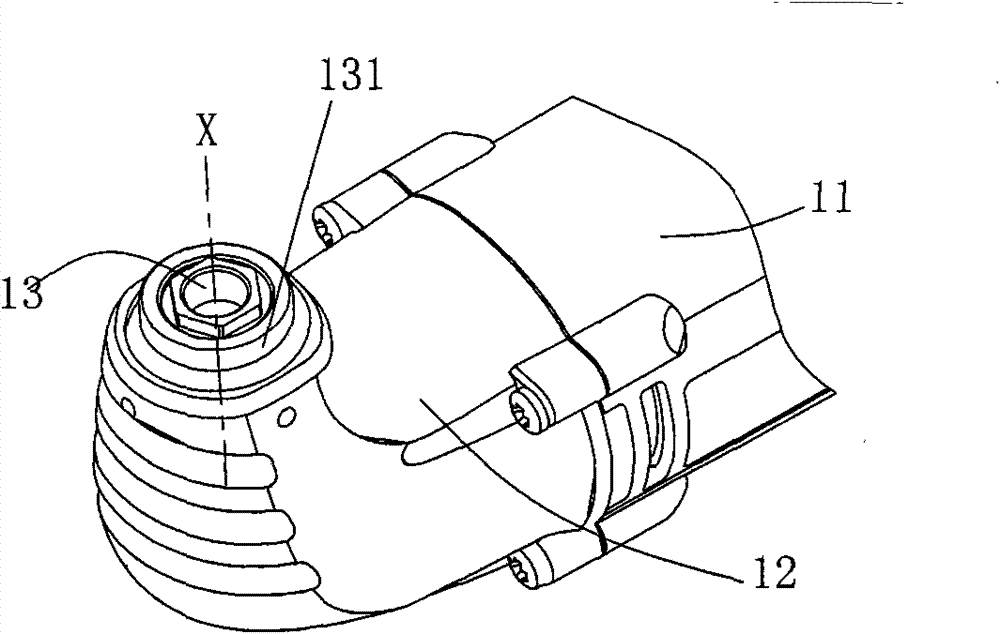

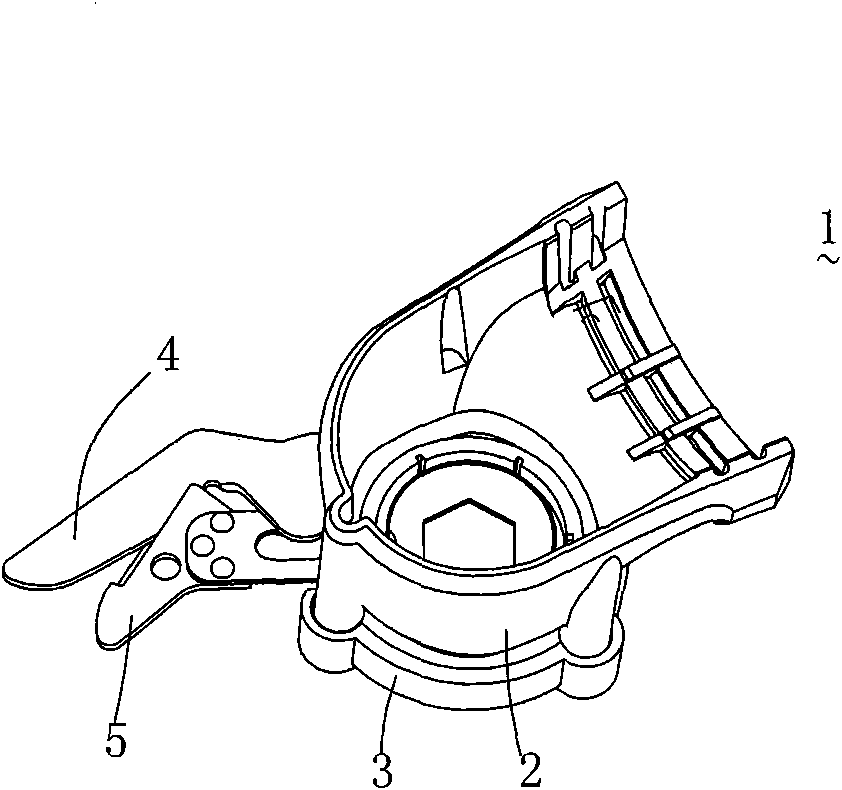

[0047] see figure 1 , a shearing tool 1 applied to an oscillating power tool, suitable for shearing operations. The oscillating power tool is designated as a reference numeral 10, and comprises a cylindrical casing 11 and is connected to the front end of the casing 11 ( figure 1 The left side of the middle is defined as the head shell 12 which is arranged roughly in an angular direction, and the output shaft 13 extends from the head shell 12 . Such as figure 2 As shown, the free end of the output shaft 13 is in the shape of a regular hexagon and has an axis X. An annular flange 131 is also formed radially at the free end of the output shaft 13 .

[0048] read on figure 1 A motor (not shown) that provides driving force and a transmission assembly (not shown) that transmits torque are arranged in the casing 11 of the swing power t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com