On-site sealed sampling device for coal bed gas

A sampling device and coal seam gas technology, applied in the direction of sampling devices, etc., can solve problems such as single conditions, impossibility to fully conform to the actual analysis of coal seam gas, simple models, etc., and achieve the effect of simple operation, strong practical value, and scientific principles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

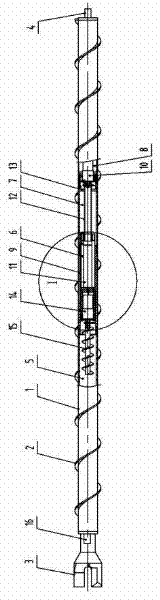

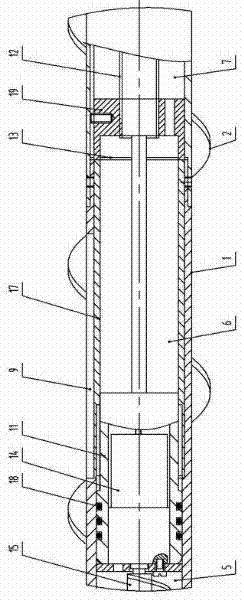

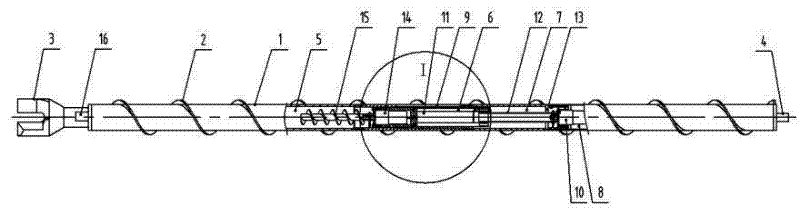

[0015] Such as figure 1 and figure 2 As shown, the coal seam gas in-situ sealed sampling device of the present invention includes a hollow long rod 1, the outer circumference of the long rod 1 is provided with spiral ribs 2, and the front and rear ends of the long rod 1 are respectively provided with coaxial The drill bit 3 and the connector 4, the inside of the long rod 1 are respectively provided with a coal storage cabin 5, a closed cabin 6, a transmission cabin 7 and a power and control cabin 8 from front to back, and the closed cabin 6 is provided with a coal inlet 9, and the transmission The cabin 7 is equipped with a reciprocating push-pull mechanism, and the power and control cabin 8 is equipped with a miniature power reduction motor 10 that provides power for the reciprocating push-pull mechanism. The front end of the cabin 5 is provided with a gas analysis hole 16 .

[0016] The inner diameter of the coal storage cabin 5 is smaller than the inner diameter of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com