Multifunctional wood working machine

A kind of woodworking machine and multi-functional technology, applied in the direction of multi-purpose machinery, wood processing equipment, manufacturing tools, etc., can solve the problems of large volume, complex structure, occupying space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

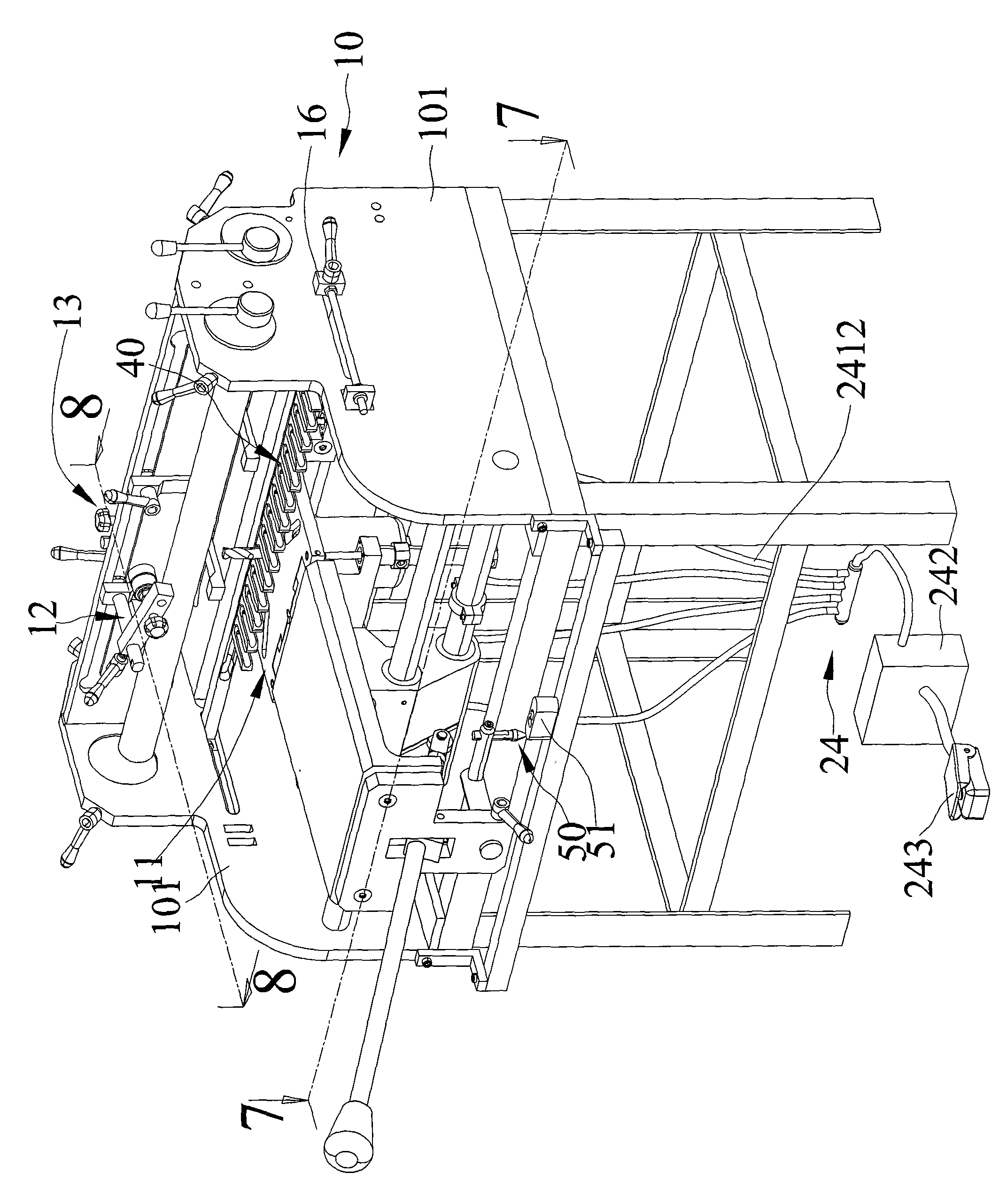

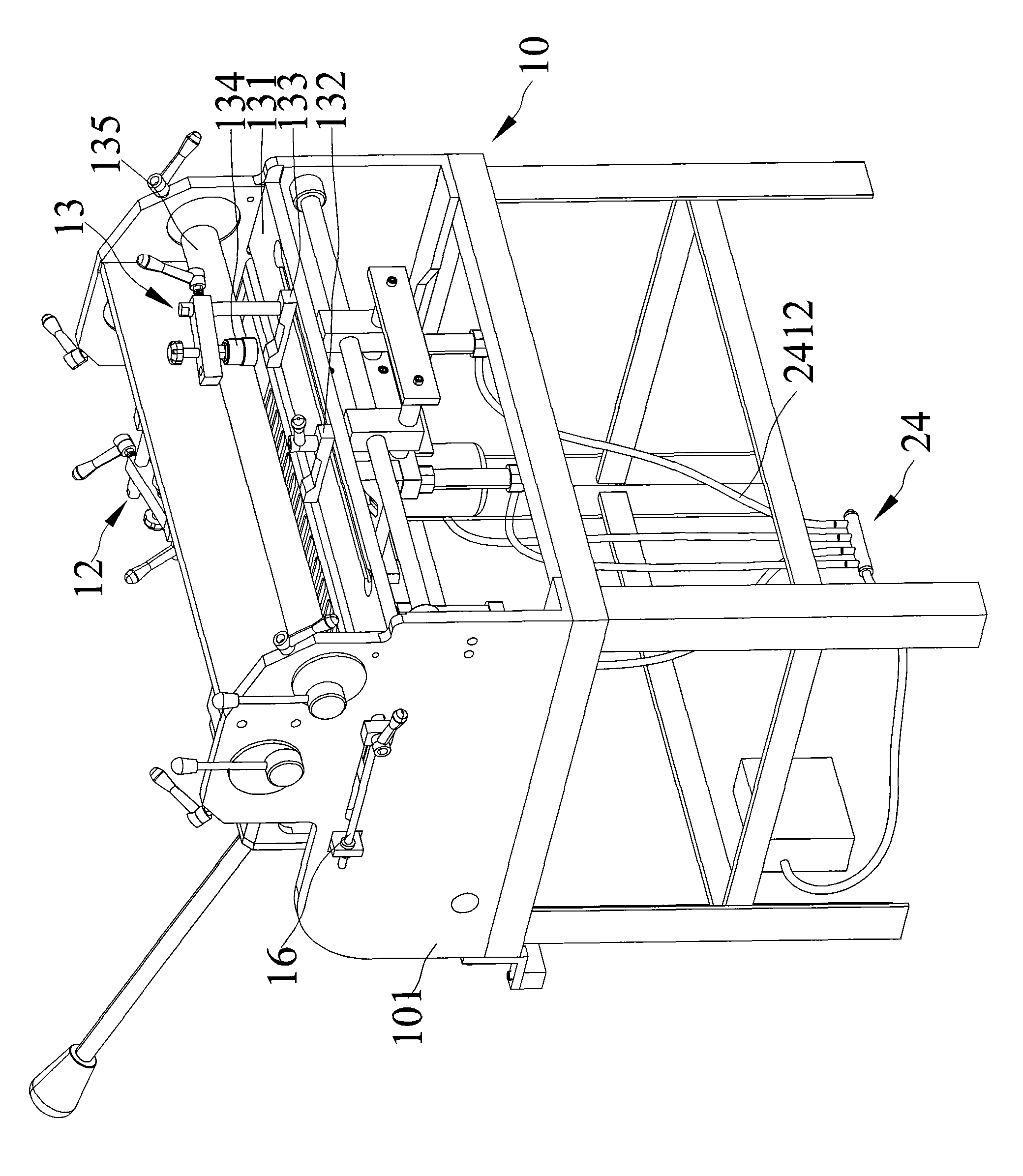

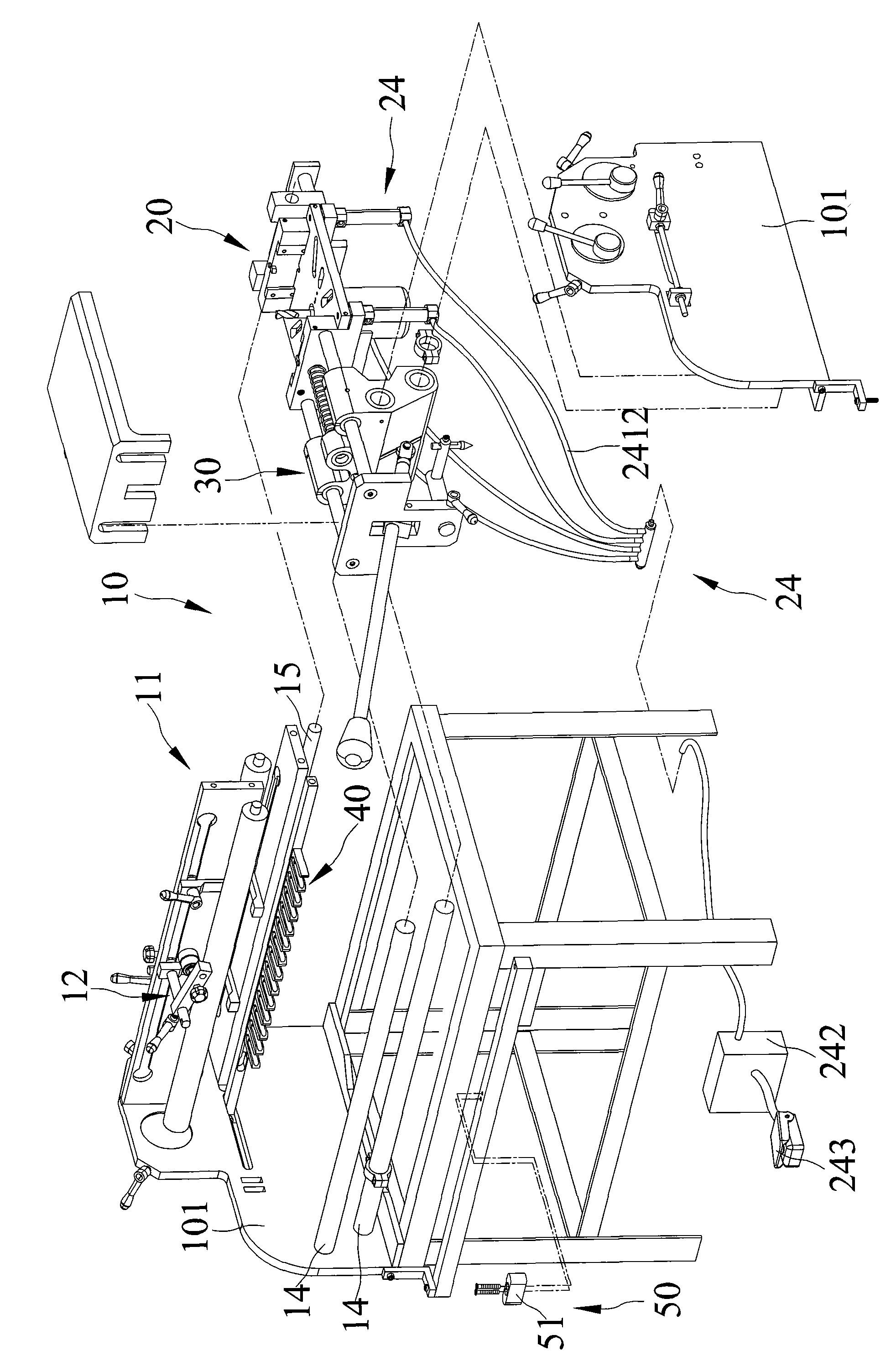

[0079] refer to Figure 1 to Figure 3 , is the three-dimensional appearance view and three-dimensional exploded view of the multifunctional woodworking machine provided by the embodiment of the present invention. The present invention includes a machine platform 10 , a workbench 20 , a traction moving device 30 and a guiding device 40 .

[0080] Also refer to Figure 4 The two sides of the top of the machine table 10 are respectively provided with side walls 101, and the top of the machine table 10 includes a placement portion 11, a first clamping device 12, a second clamping device 13, two first slide bars 14 and A second slide bar 15. The placement part 11 is used to place the work object, and the work object can be placed on the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap