Once reciprocating reverse jacking type capsule de-molding machine

A technology of demolding machine and reciprocating mechanism, which is applied in the directions of capsule delivery, drug delivery, pharmaceutical formulation, etc., can solve the problems such as being unsuitable for large-scale production line matching, large body of the demolding machine, unfavorable for large-scale production line matching application, etc. Large-scale production line matching, compact and compact body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

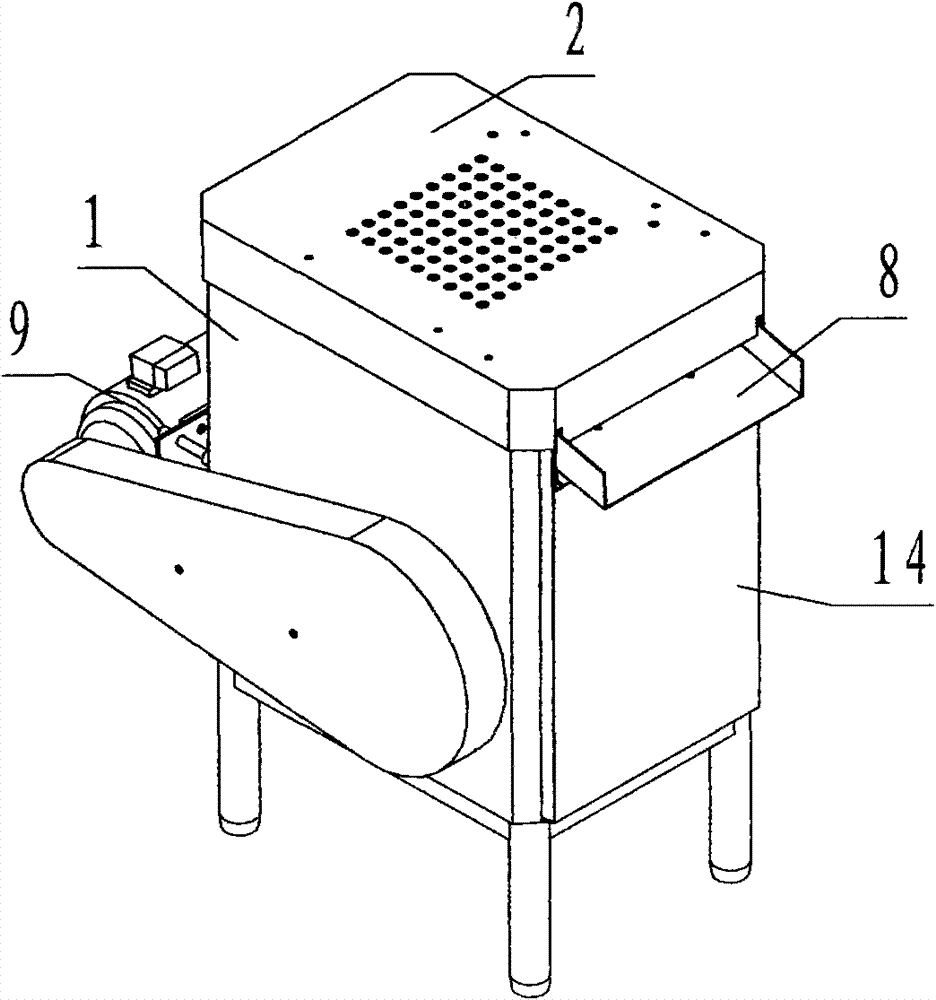

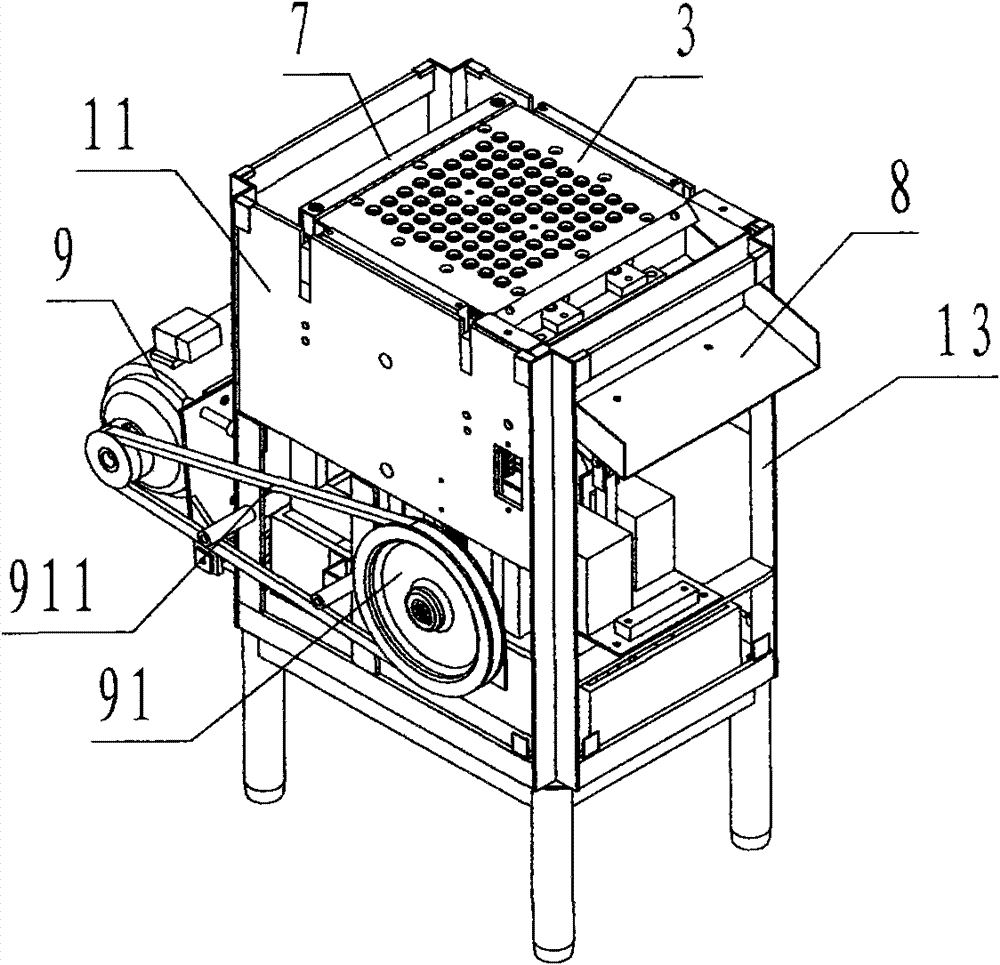

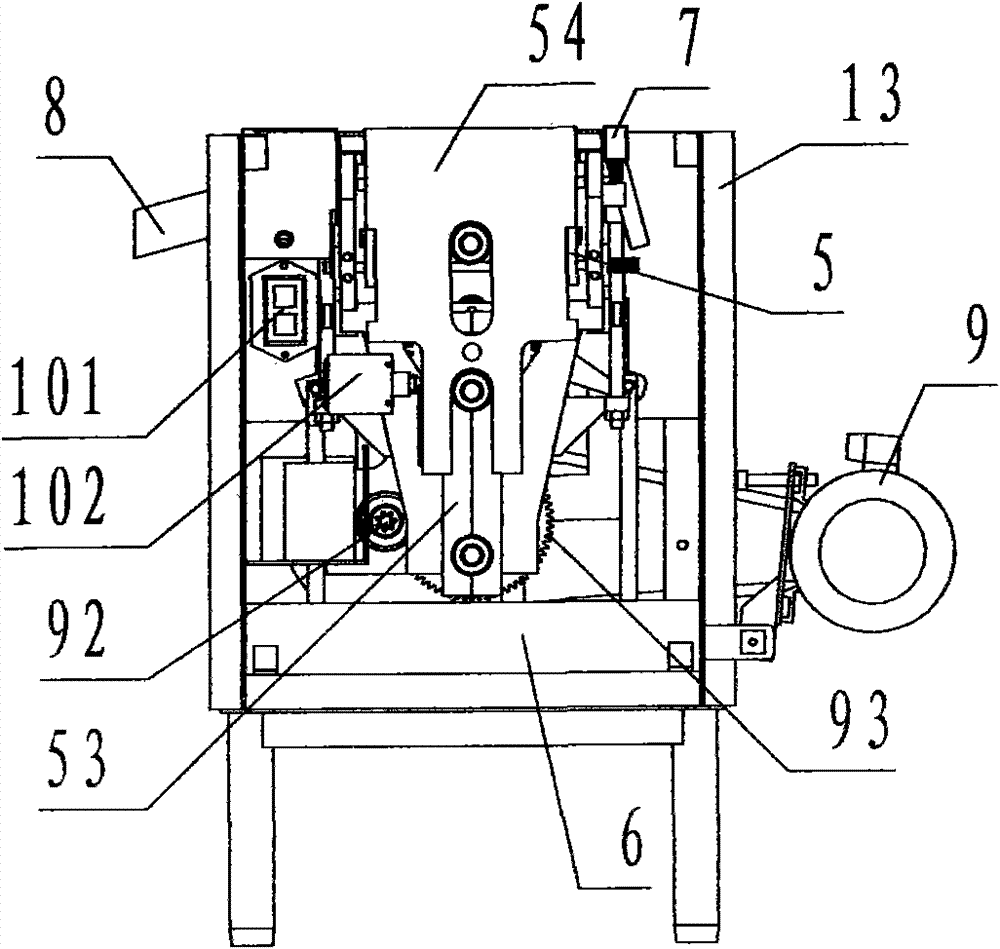

[0043] refer to Figure 1 to Figure 11 , a reciprocating one-time inverted capsule demoulding machine of the present invention, comprising a body 1, a lifting cover 2, a clamping plate 3, a tube jacking plate 4, a ejector rod plate 5, a bellows 6, a tuyere 7, an inclined bucket 8, Tube jacking reciprocating mechanism, ejector plate reciprocating mechanism, piston reciprocating mechanism, power transmission mechanism, and electrical control system, wherein: the body 1 includes wall panels 11, support plates 12, brackets 13, shells 14, and beam plates 15 , used to carry the steel frame body of each part of the capsule demoulding machine; the bracket 13 is a frame body made of angle steel to form the twelve edges and the bottom of the rectangular body 1; two wall panels 11 and two beam panels 15 The frame beam plate that surrounds a rectangle is fixed on the top of the support 13, the wall plate 11 is positioned at the two sides overlooking the long side of the body 1, the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com